Gas outlet valve with dual-ball sealing

A technology of air outlet valve and air outlet, which is applied in valve details, multi-way valves, control valves, etc., can solve the problems of lack of reliability, complex structure, and many accessories, so as to increase the flowable space of gas, reduce collision wear and high The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

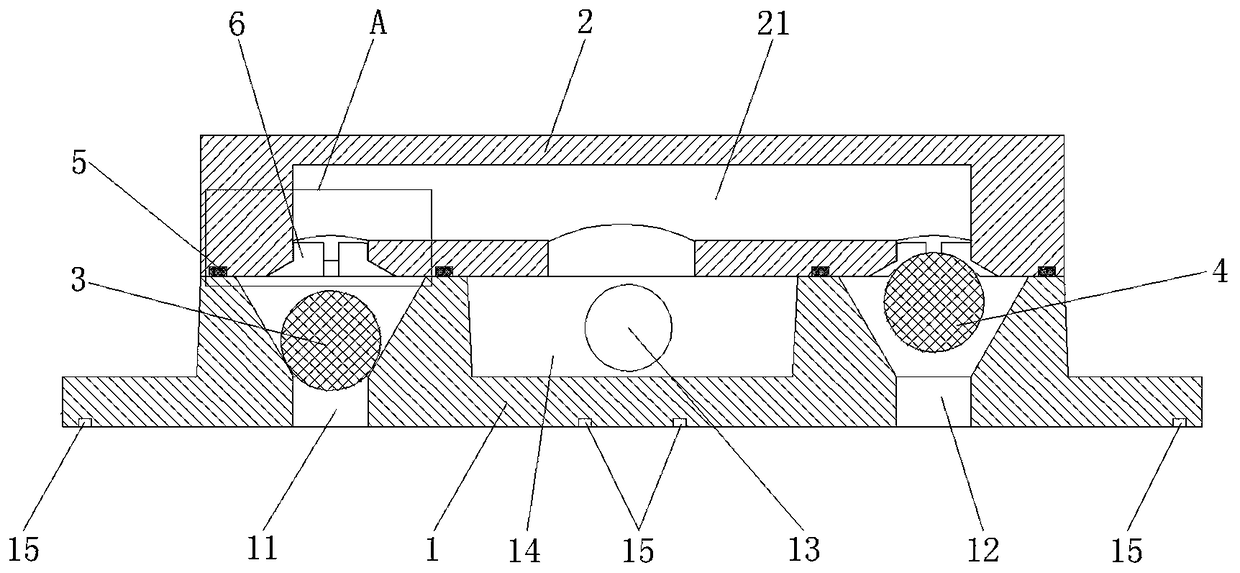

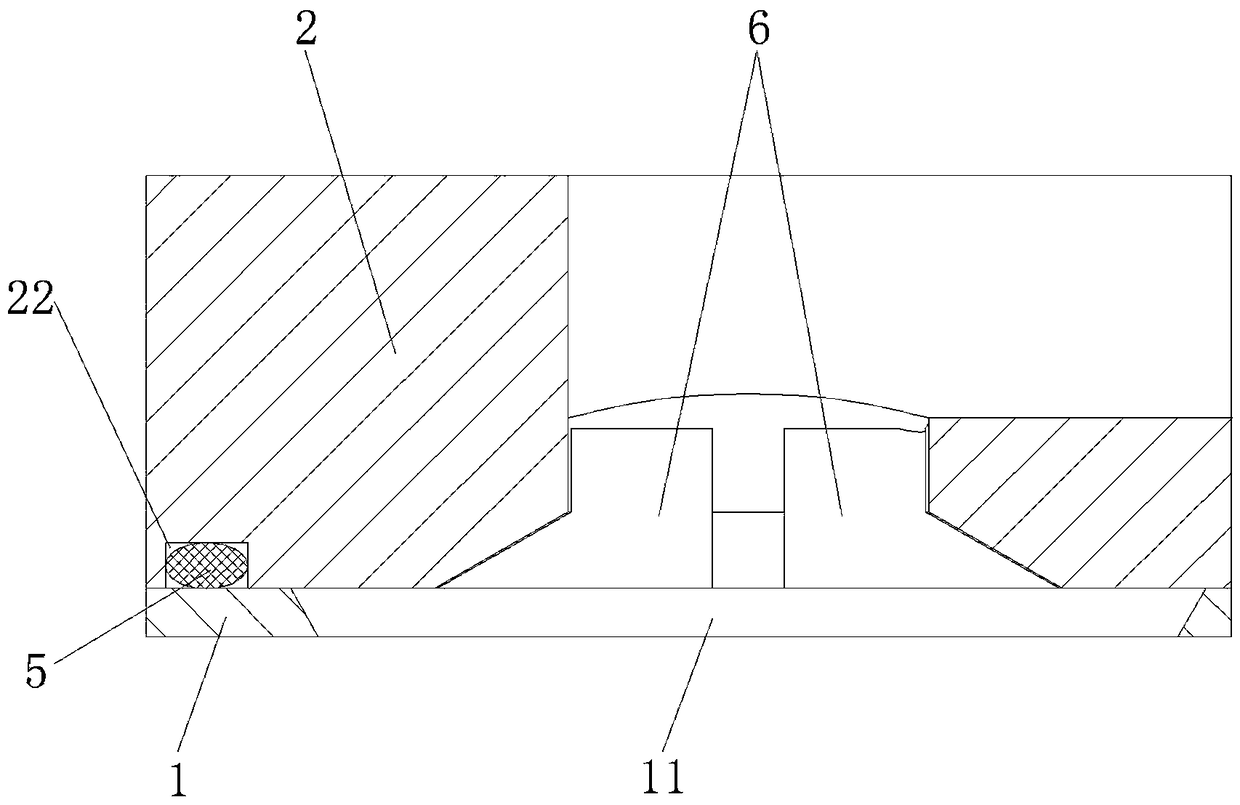

[0022] like figure 1 and figure 2 As shown, in this embodiment, the present invention includes a valve body 1 and a valve cover 2 matched with the valve body 1. The valve body 1 is provided with a tower A gas outlet 11, a B tower gas outlet 12 and a valve body gas outlet 13, the valve cover 2 is provided with an AB tower gas outlet confluence pipe 21, and the AB tower gas outlet confluence pipe 21 corresponds to the A tower gas outlet 11, the B tower gas outlet 12 and the valve body The air outlets 13 are all provided with through holes, the air outlet 11 of the A tower is provided with the A tower sealing ball 3, and the B tower air outlet 12 is provided with the B tower sealing ball 4. The gas outlet 11 of tower A and the gas outlet 12 of tower B both include an upper section and a lower section, the upper section is a funnel-shaped opening, and the lower section is a cylindrical through hole. The A tower sealing ball 3 can move up and down at the gas outlet 11 of the A t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com