A mechanical micro-sample rapid sampling mechanism

A fast and mechanical technology, applied in the direction of sampling device, etc., can solve the problems of difficult sample acquisition, no non-destructive or micro-destructive rapid sampling device, etc., and achieve the effect of ensuring centering, compact structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

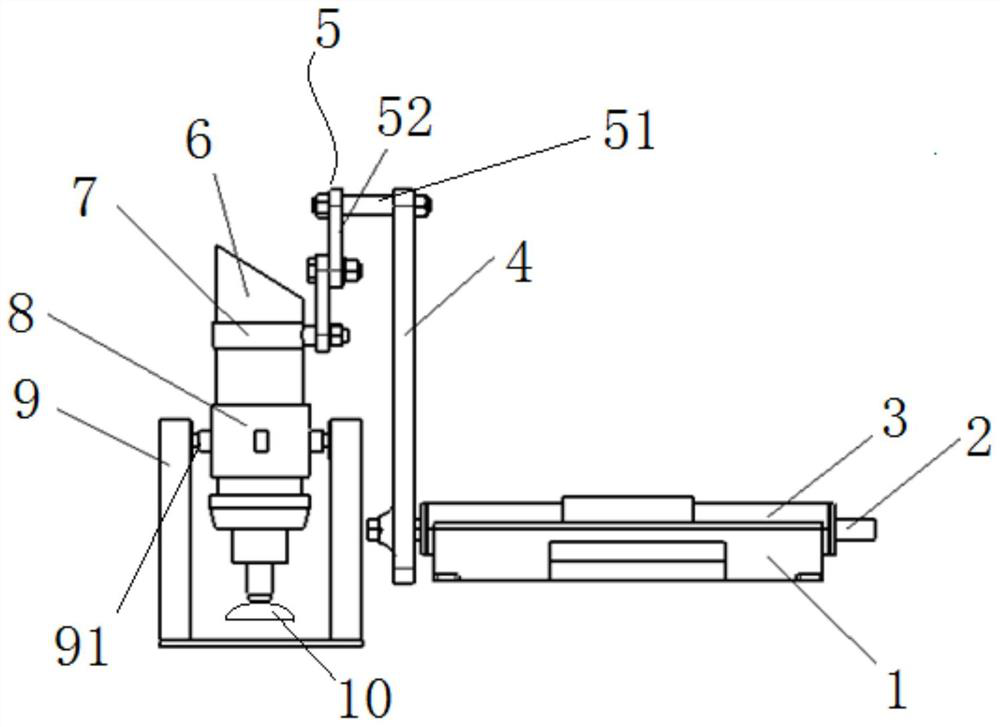

[0023] A mechanical micro-sample rapid sampling mechanism, its structure is as follows figure 1 shown, including:

[0024] Base 9: the top is provided with a horizontal rotating shaft 91;

[0025] Cutter unit 5: comprising a rotary motor 6 and a sampling tool 10 connected to the rotary motor 6, the middle part of the rotary motor 6 is fixed with a hoop frame 8, and is rotatably connected to the horizontal rotating shaft 91 through the hoop frame 8;

[0026] Swing unit: including a box body composed of a base 1 and an upper cover 3, a main shaft 2 fixedly arranged inside the box body, a drive motor (not shown in the figure) arranged at one end of the main shaft 2, and a bottom end fixedly arranged on the main shaft 2 The swing rod 4 at the other end and the ferrule 7 connected to the top of the swing rod 4 through the connection unit 5, the ferrule 7 is sleeved on the upper end of the rotating motor 6.

[0027] Wherein, the connecting unit 5 includes a connecting rod 51 verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com