Fast connecting device realizing heavy current charge and discharge

A fast connection, charge and discharge technology, applied to the parts, connections, coupling devices, etc. of the connection device, can solve the problems of insufficient stability, easy disconnection, large connector size, etc. The effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

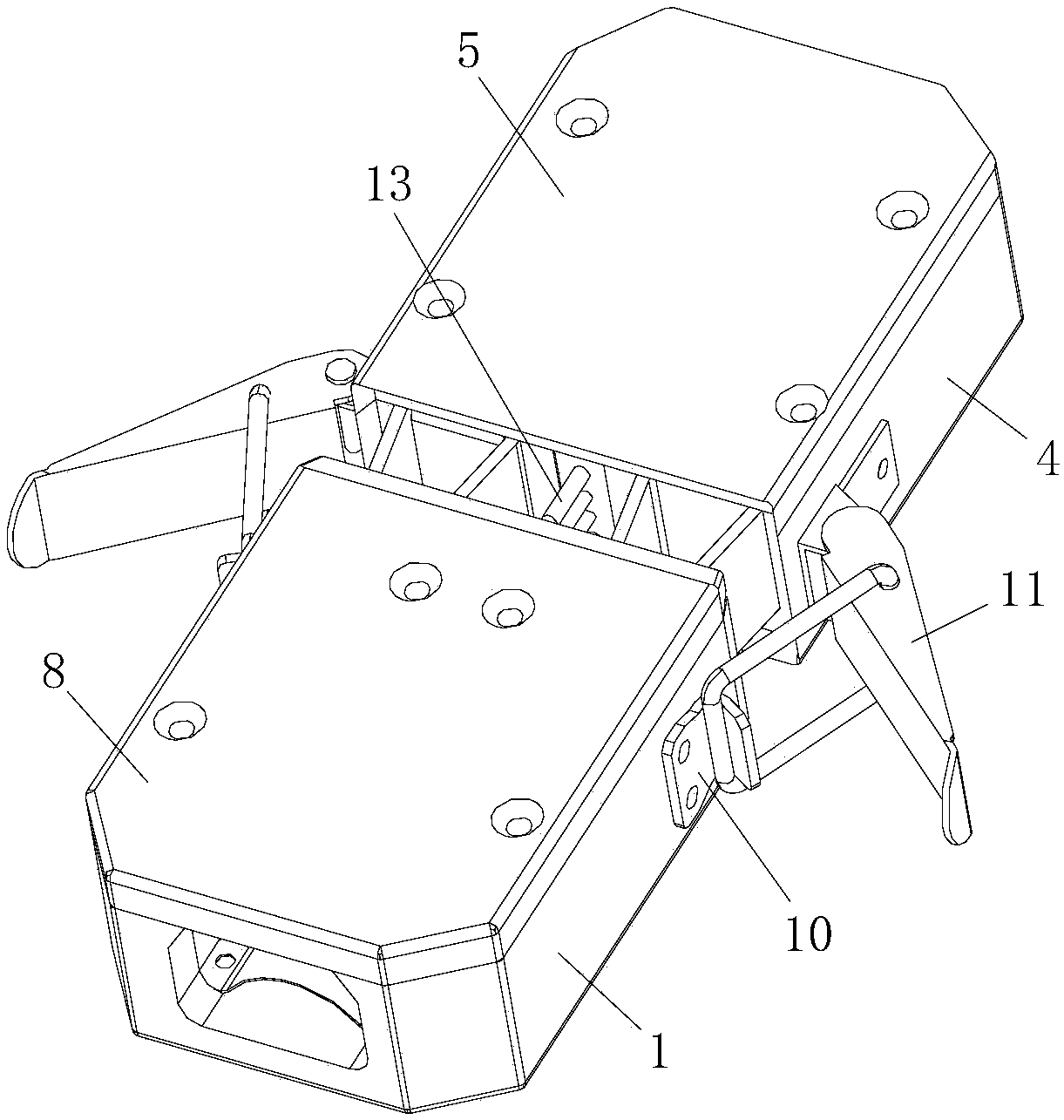

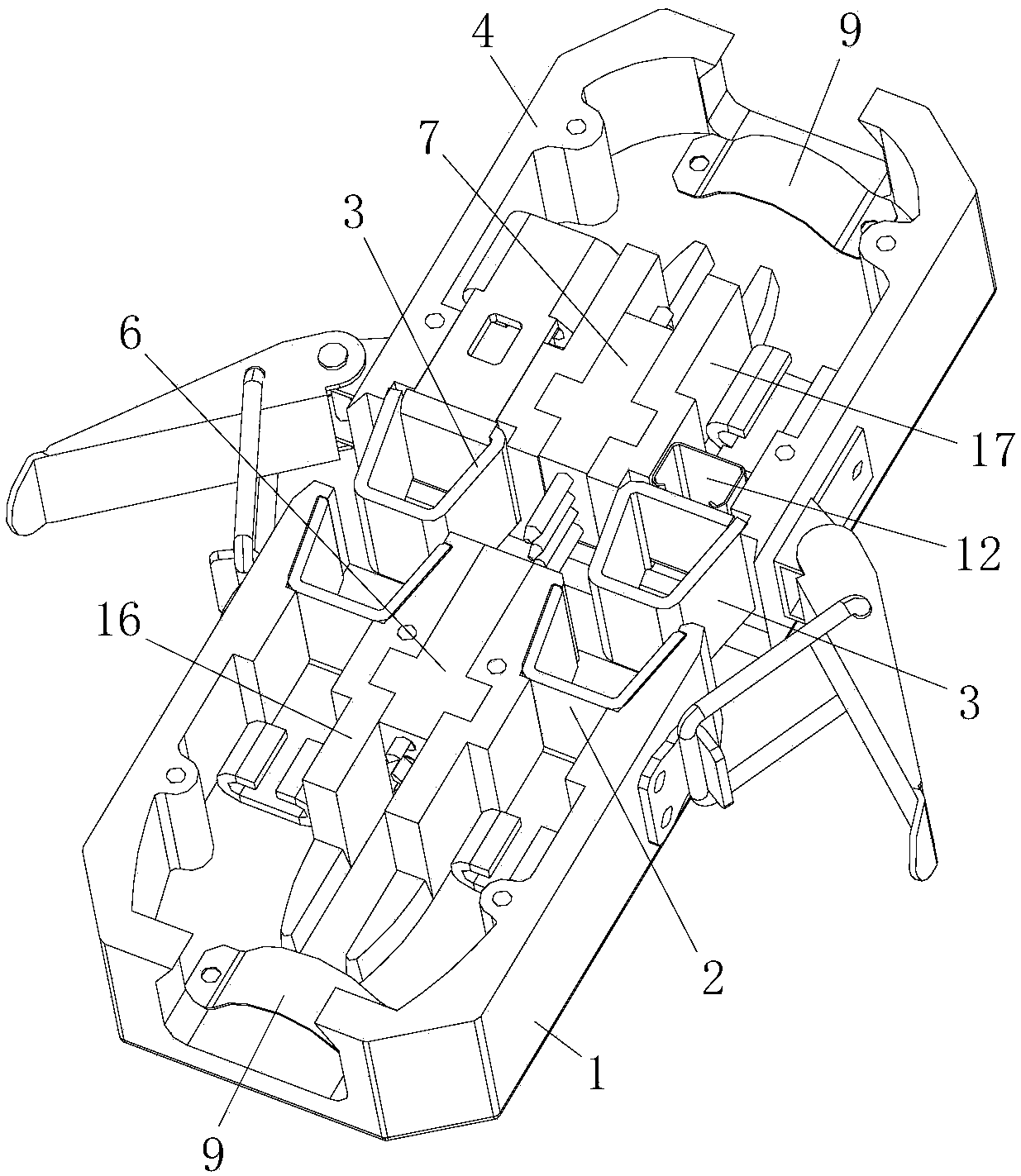

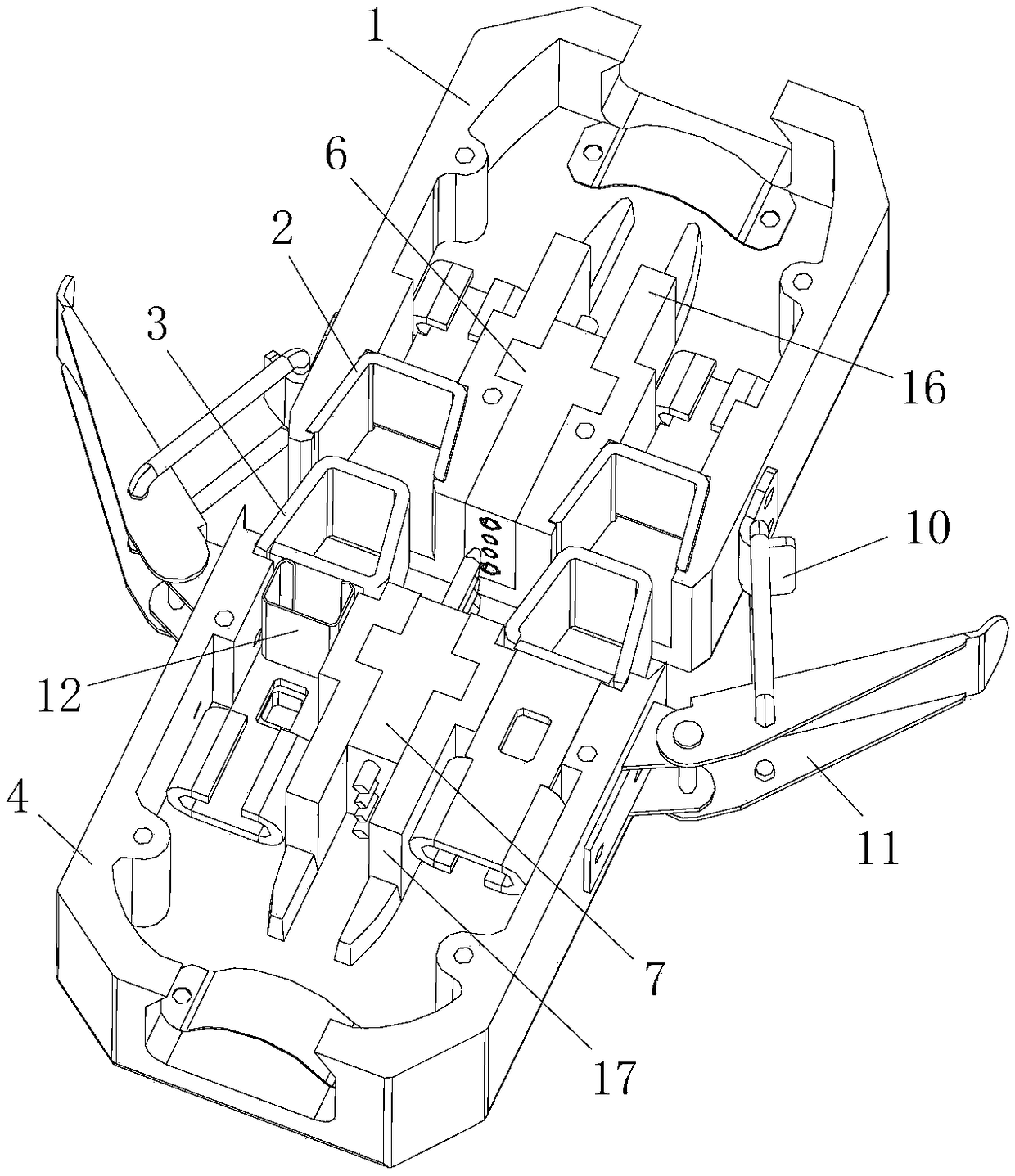

[0020] In this example, refer to Figure 1-Figure 4 , the fast connection device that can realize high-current charging and discharging includes two parts: a fixed seat and a movable seat, and a conductive structure that is electrically connected is formed by inserting and docking the conductive contact end of the movable seat and the conductive contact end of the fixed seat; The seat includes a fixed base 1, and a wedge-shaped female end 2 is fixed in the fixed base. The wedge-shaped female end 2 is bent into a U-shaped structure by a conductive metal sheet, and the width of the opening is larger than the inner width. The wall is a fixed groove with a slope structure and matches the shape of the wedge-shaped female end 2. The wedge-shaped female end 2 is fastened in the fixed groove, and the wedge-shaped female end 2 is located at the side where the fixed base 1 and the movable seat are docked. inside the side tail;

[0021] The movable seat includes a movable base 4, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com