Crescent moon type scissor saw

A technology of scissors and crescents, which is applied in the field of crescent scissors and saws, can solve the problems of easy fatigue, inconvenient use of back and forth replacement, increased labor workload of workers, etc., and achieve the effect of labor-saving sawing efficiency and reduced load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

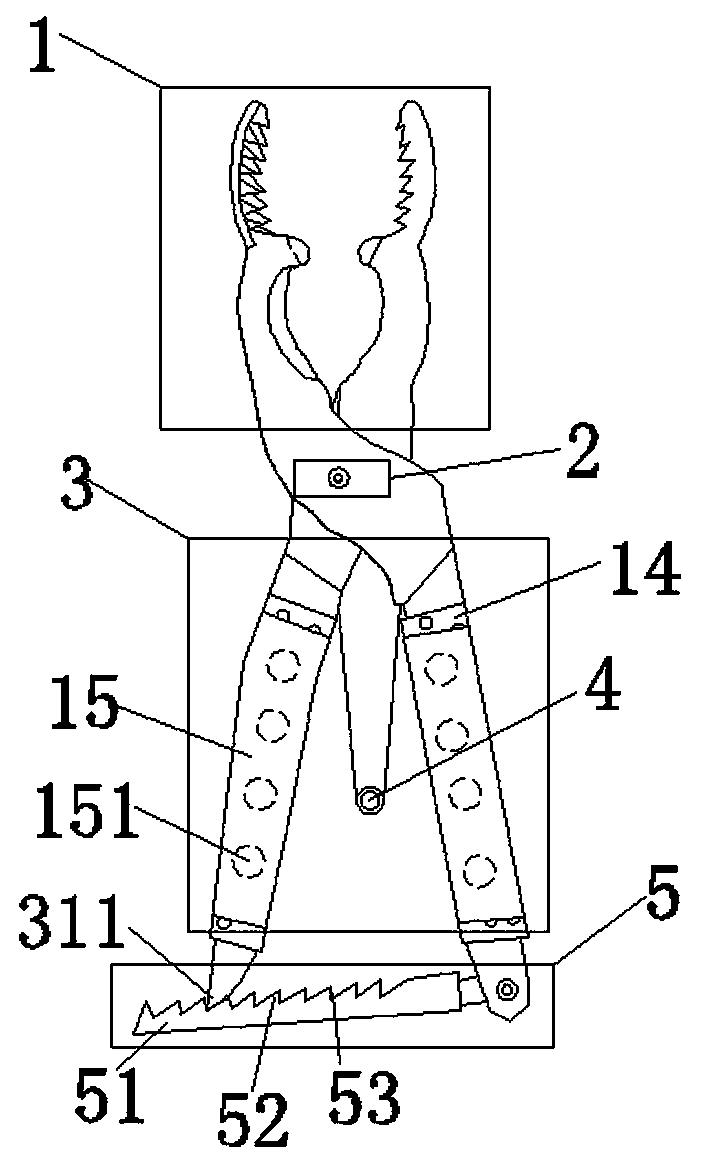

[0048] Such as figure 1 As shown, the teeth of the serrated edge I7 are single oblique serrations 11, the teeth of the serrated edge II72 are single oblique serrations 11, and the teeth of the serrated edge I71 are inclined toward the 3 end of the handle, and the serrations The inclination direction of the tip of the blade Ⅱ72 is the same as that of the tip of the sawtooth of the blade I71; the inclination angle α of the blade of the sawtooth part 7 in the vertical direction of the scissors saw is in the range of 75°≤α <90 degrees, the tooth groove 73 at the tooth root of the serrated edge portion 7 is connected with a chip discharge groove 74.

[0049] The 3 heads of the knife handle are provided with a return device. The return device is a locking mechanism 5. The locking mechanism 5 includes a buckle 311 and a groove strip 51 matched with the buckle. The buckle 311 is arranged on the handle head of the knife handle I 31 On the upper side, one end of the groove strip 51 is con...

Embodiment 2

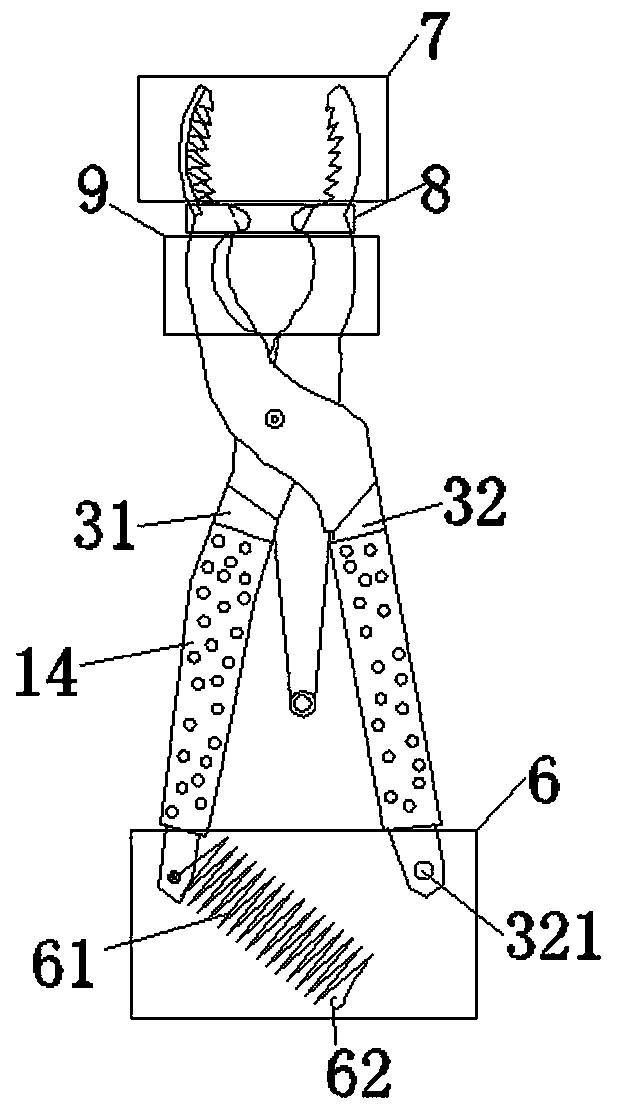

[0054] Such as figure 2 As shown, the biggest difference between this embodiment and Embodiment 1 lies in the difference in the return device. In this embodiment, the return device on the head of the knife handle 3 is a spring mechanism 6. The spring mechanism 6 includes a return spring 61. One end of 61 is connected with the head of the knife handle I 31, and the other end of the return spring 61 is provided with a hook 62, and the hook 62 is detachably hooked into the hook hole 321 provided on the head of the knife handle II 32.

[0055] Such as Figure 14 As shown, in the prior art, the worker applies pressure and thrust to the hand saw 16 during the reciprocating sawing process of the hand saw, which prompts the hand saw 16 to reciprocate back and forth. It is not difficult to see that the worker can only exert force on one side of the branch 13 during sawing. , The cutting efficiency is low.

[0056] The design concept of this patent is that one is to combine the pruning shear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com