Cap feeding device of encapsulated edible oil container

A technology for edible oil and containers, which is applied in the field of cap feeding devices for packaging edible oil containers, which can solve the problems of cap conveying jamming, inconvenient operation, and uneven space spacing of slideways, etc., and achieves high degree of automation, convenient operation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

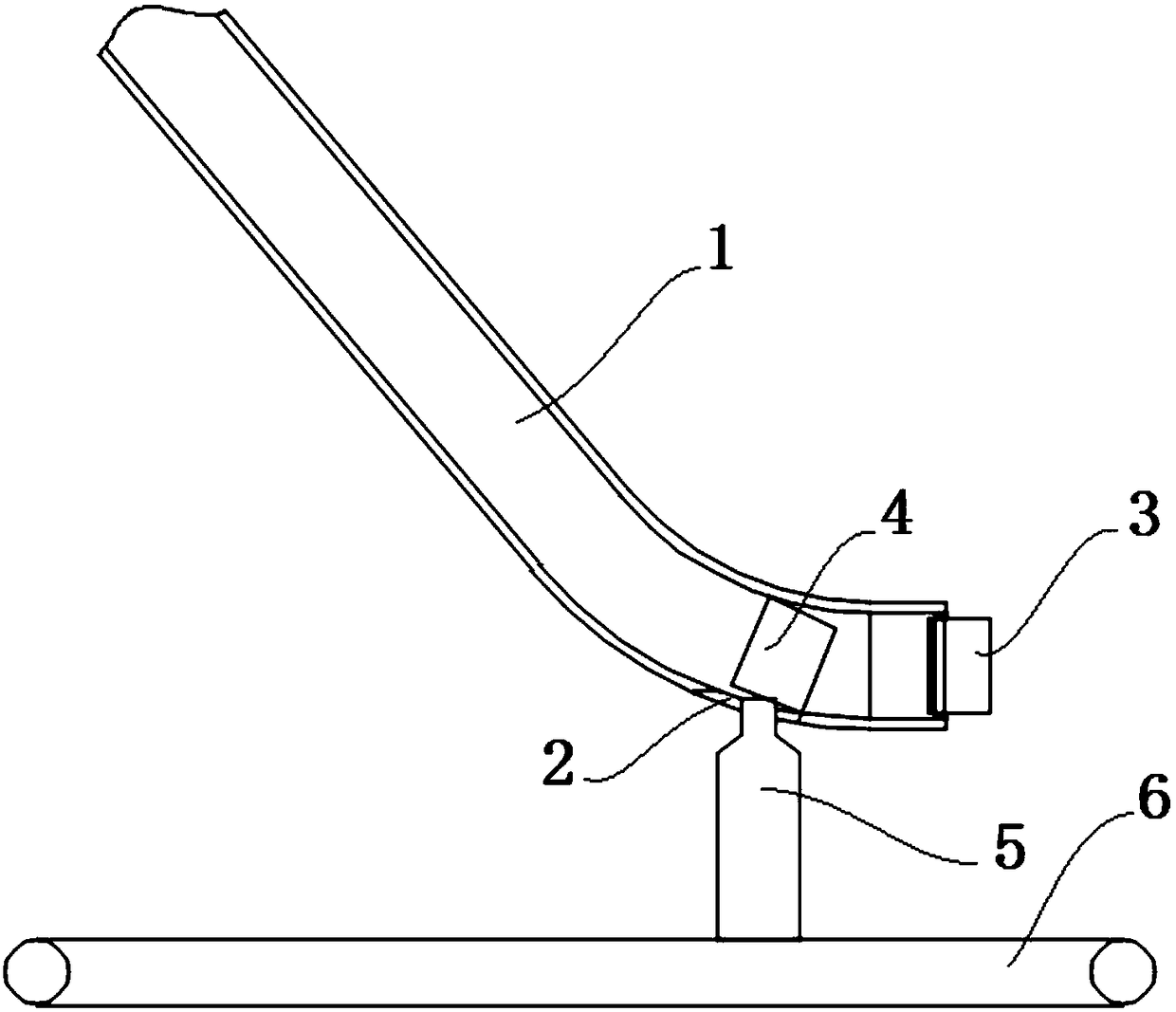

[0017] Such as figure 1 As shown, a cap feeding device for packaging edible oil containers of the present invention includes a bottle cap conveying slide 1, the bottle cap conveying slide 1 is placed in an inclined shape, and the bottle cap 4 is affected by its own gravity on the bottle cap conveying slide 1 Automatically slide down, the bottom of the bottle cap conveying slideway 1 is provided with an edible oil container cover notch 2, and the bottle cap 4 cross section on the edible oil container cover notch 2 forms a set angle with the horizontal plane. The included angle is 45 degrees. The outlet end of the bottle cap conveying slide 1 is provided with an elastic baffle 3. There are two elastic baffles 3. The two elastic baffles 3 are respectively located at the left and right ends of the outlet end of the bottle cap conveying slide 1. Two elastic baffles 3 are hinged to the bottle cap conveying slide 1, and the two elastic baffles 3 are used to close the outlet of the bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap