Approximate closed steel box and spring buffer layer

A buffer layer and spring-added technology, which is applied in the field of bridge structure construction, can solve the problem that the rigid structure is difficult to enlarge, and achieve the effect of reducing the scale of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in combination with specific embodiments.

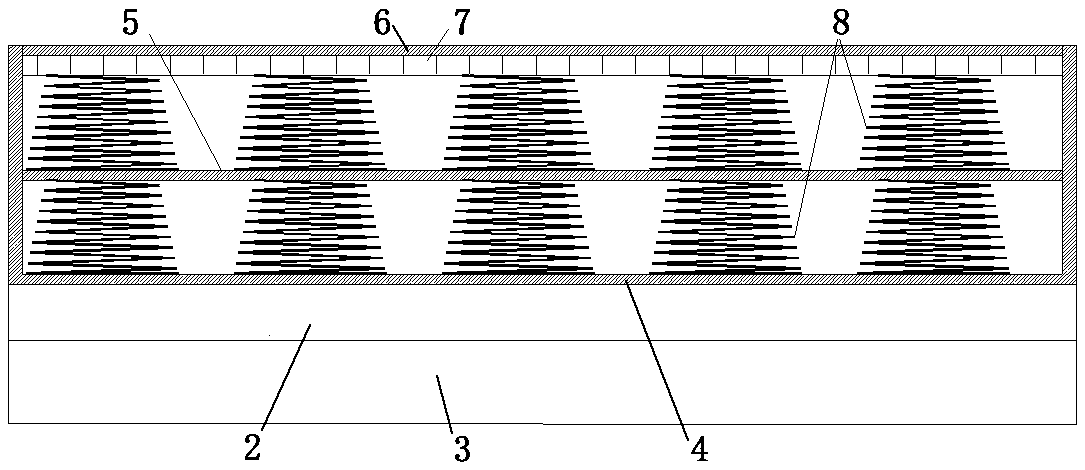

[0031] The invention relates to an approximately airtight steel box with a spring buffer layer. The design principle is to use spring compression to prolong the action time of the pulse force, and to use the air pressure difference between the inside and outside of the approximately airtight steel box to reduce the damage of the pulse force.

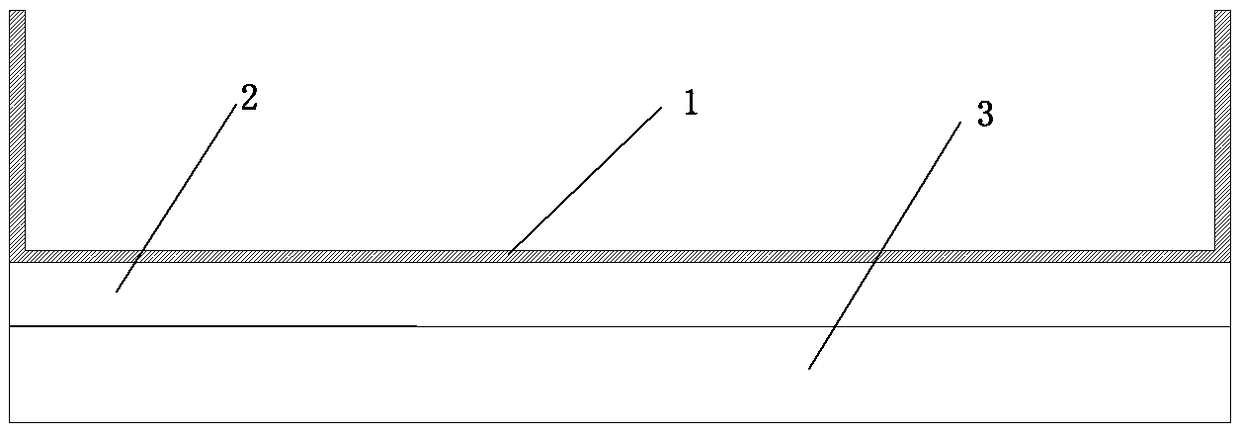

[0032] The buffer layer is arranged above the structural layer on the top of the rockfall prevention structure, including a steel box 1 without a top surface, about 0.6m high, and the bottom surface of the steel box 1 has the same area as the structural layer. Springs 8 are evenly arranged in the steel box 1, and the top of the springs 8 is provided with an upper steel plate 6, and the bottom of the upper steel plate 6 is welded with a steel grid 7 for enhancing the rigidity of the top steel plate. The upper steel plate 6 and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com