Telescopic vehicle blocking rod device based on security technology and protection engineering

A safety technology, the technology of the traffic stop bar, which is applied in the field of telescopic traffic stop bar device, can solve the problems of large inertia and easy damage of the traffic stop bar, and achieve the effect of small inertia, rapid expansion and contraction, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

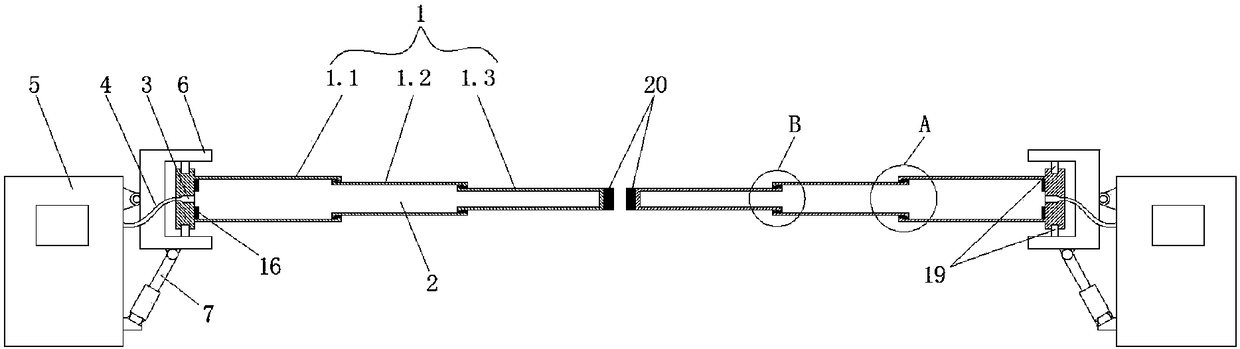

[0027] like Figures 1 to 5 As shown in the figure, this embodiment provides a telescopic parking bar device based on safety technology prevention engineering, including two symmetrically arranged parking bar assemblies 1, and the parking bar assembly 1 includes a first-stage hollow rod 1.1, a second-stage The hollow rod 1.2 and the third-stage hollow rod 1.3, the second-stage hollow rod 1.2 is movably clamped in the first-stage hollow rod 1.1, the third-stage hollow rod 1.3 is movably clamped in the second-stage hollow rod 1.2, the first-stage hollow rod 1.2 The interior of the hollow rod 1.1, the second-stage hollow rod 1.2 and the third-stage hollow rod 1.3 communicate with each other and form a closed cavity 2. The side end of the first-stage hollow rod 1.1 away from the second-stage hollow rod 1.2 is provided with a cavity 2. The connected oil hole 3, the oil hole 3 is connected with the oil pipe 4, the other end of the oil pipe 4 is connected with the hydraulic station 5...

Embodiment 2

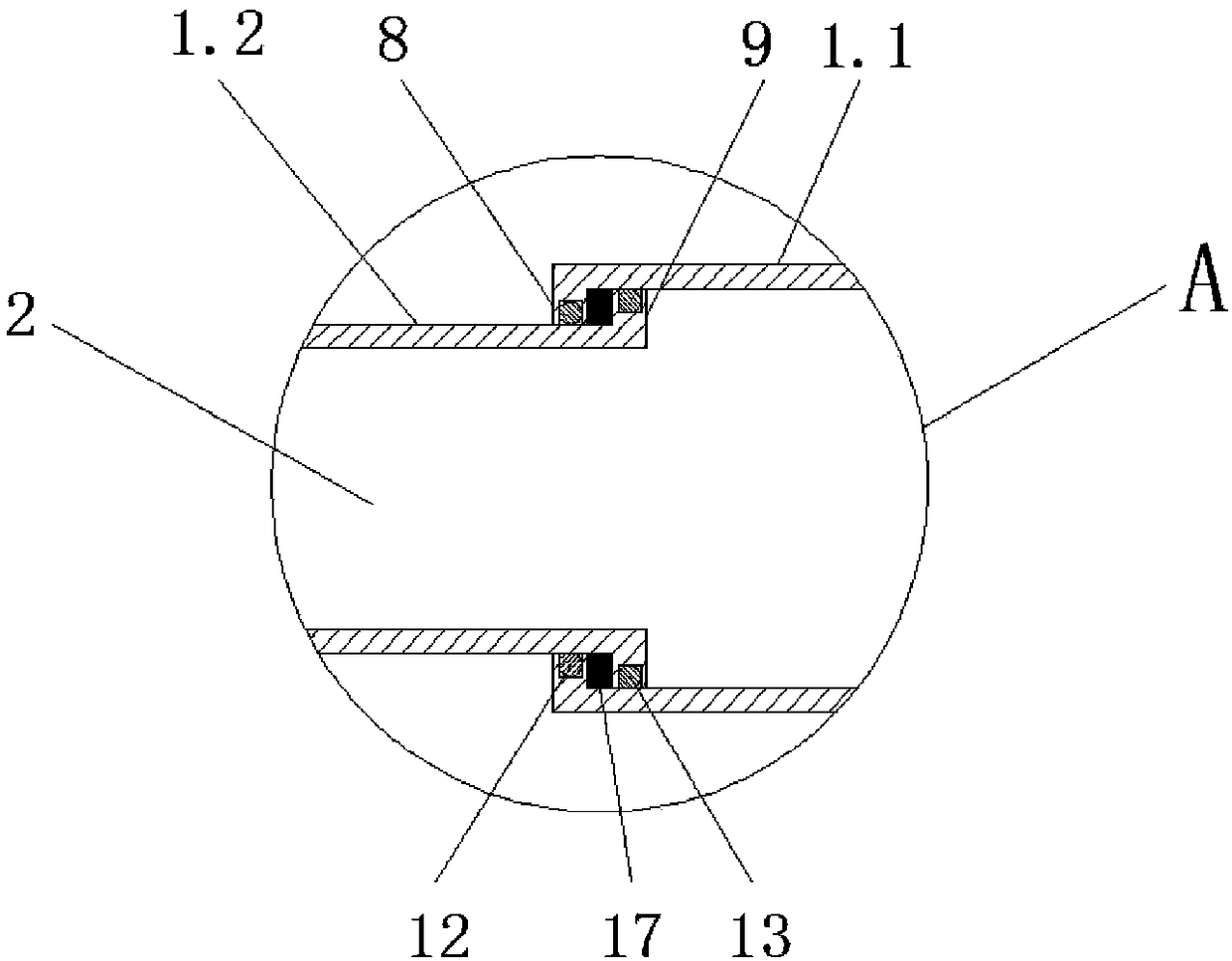

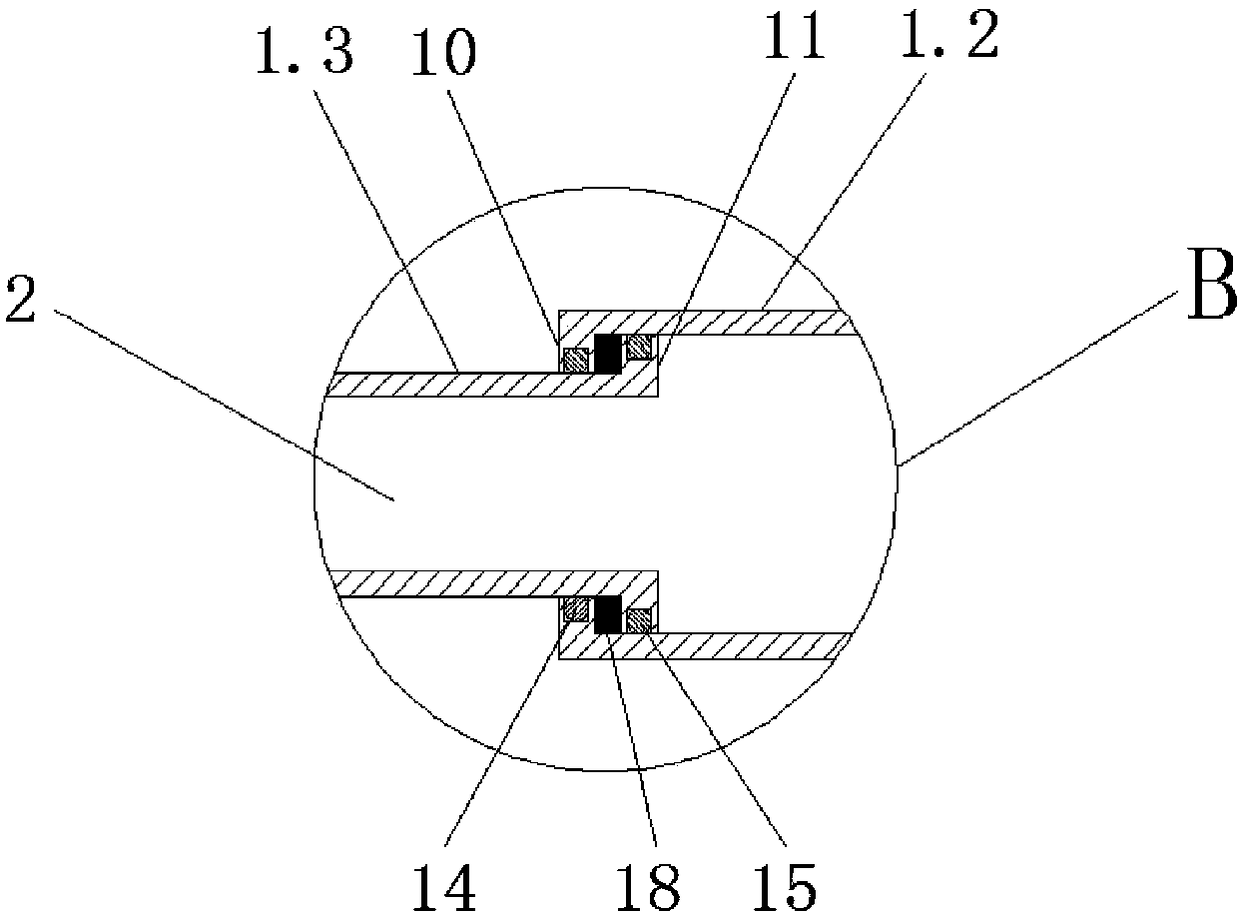

[0030] like Figures 1 to 3 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the end of the first-stage hollow rod 1.1 away from the seat body 6 is provided with a circle of inwardly turned bosses A8, and the second-stage hollow rod One end of 1.2 is provided with a circle of bosses B9 that are turned outwards and matched with the bosses A8. The bosses B9 are close to the inner wall of the first-stage hollow rod 1.1, and the other end of the second-stage hollow rod 1.2 is provided with a circle of inward-turned protrusions. In the stage C10, one end of the third-stage hollow rod 1.3 is provided with a circle of bosses D11 that are turned outward and cooperate with the boss C10, and the boss D11 is close to the inner wall of the second-stage hollow rod 1.2.

[0031] In this embodiment, when the boss D on the third-stage hollow rod clamps the boss C on the second-stage hollow rod, the third-stage hollow rod and the second-stage hollow ro...

Embodiment 3

[0033] like Figures 1 to 3 As shown, this embodiment is further optimized on the basis of Embodiment 2. Specifically, the boss A8 is provided with a number of universal balls A12 in contact with the outer wall of the second-stage hollow rod 1.2, and the boss B9 is provided with a A number of universal balls B13 in contact with the inner wall of the first-stage hollow rod 1.1, a number of universal balls C14 in contact with the outer wall of the third-stage hollow rod 1.3 inside the boss C10, and a number of universal balls C14 in contact with the second-stage hollow rod inside the boss D11. The universal ball D15 that the inner wall of the rod 1.2 contacts.

[0034] In this embodiment, when the third-stage hollow rod slides in the second-stage hollow rod, the arrangement of the universal ball C and the universal ball D can reduce the friction between the third-stage hollow rod and the second-stage hollow rod In the same way, when the second-stage hollow rod slides in the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com