Rotary compression tampon device

A tampon, rotary compression technology, applied in the direction of tampons, absorbent pads, etc., can solve the problems of difficulty in simplifying equipment and working time, difficulty in improving production efficiency, and monopolizing the market by large enterprises, so as to improve efficiency and quality, and prolong Longevity, fast absorption of menstrual blood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

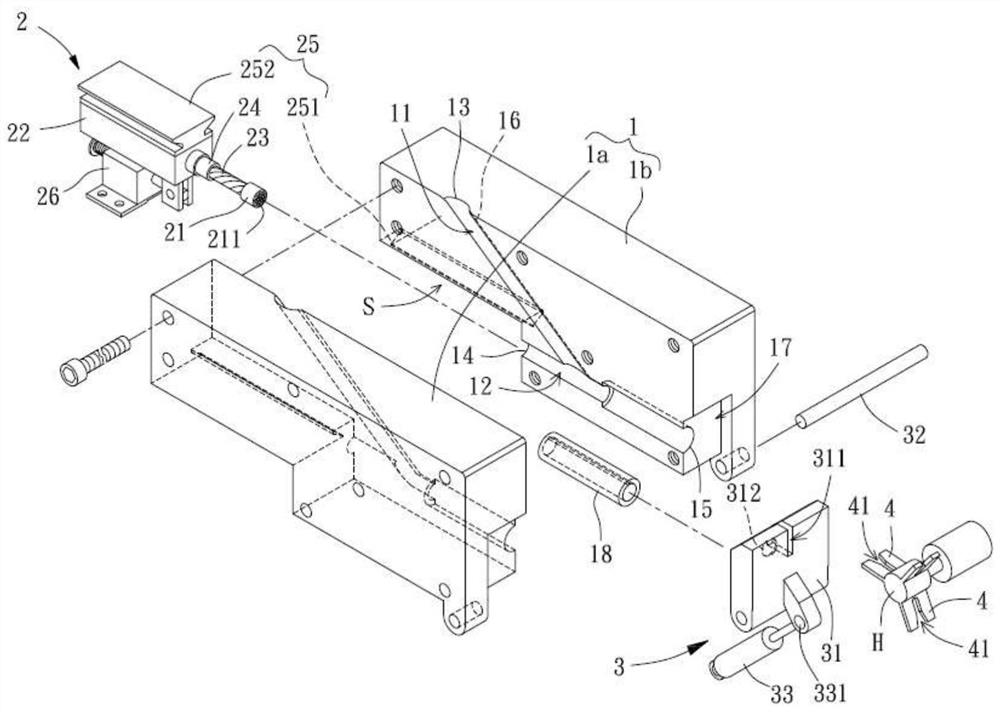

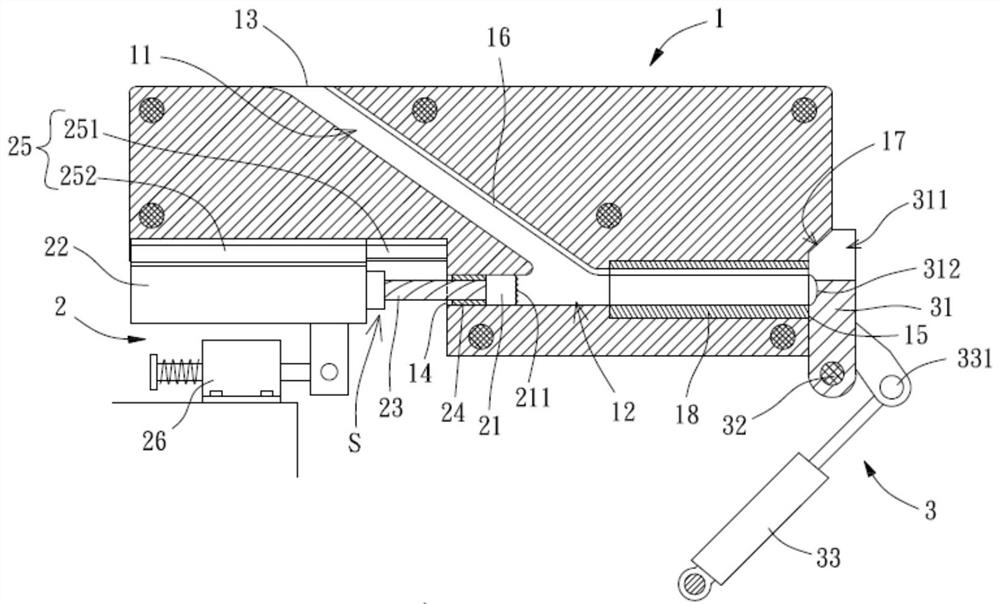

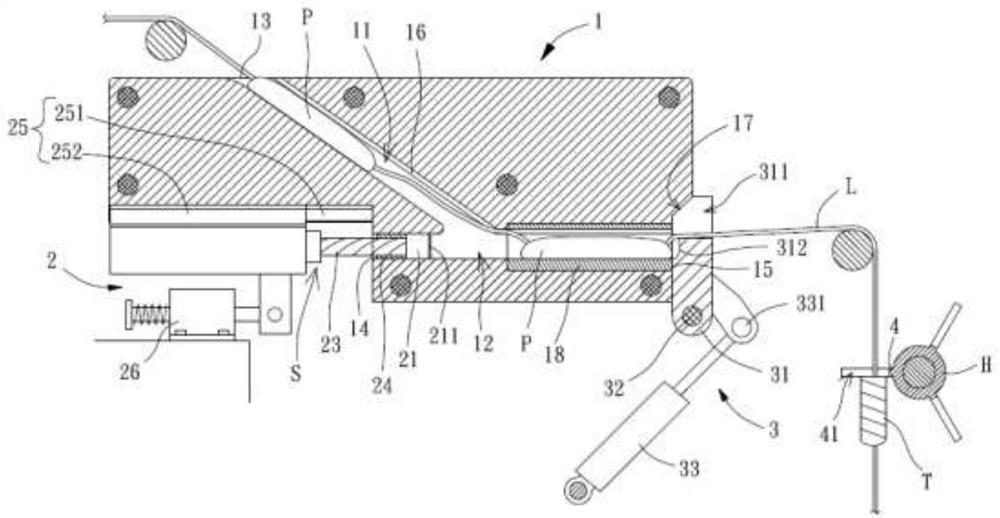

[0042] Please refer to Figures 1 and 2, which is a preferred embodiment of the rotary compression tampon device of the present invention, which includes a mold base 1, a stamping module 2 and a closure assembly 3, the stamping module 2 and the The closing component 3 is movably arranged on the mold base 1 .

[0043] The inside of the mold base 1 has a guide channel 11 and a punching channel 12, the first end of the guide channel 11 has an introduction port 13, the introduction port 13 can be located on the outer surface of the die base 1, the guide The second end of the channel 11 communicates with the punching channel 12 , so that the sliver preform to be compressed is introduced from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com