Automatic loading and unloading drill pipe device and control method for coal mine tunnel drilling rig

A technology for tunnel drilling rigs and drill pipes, which is applied to drill pipes, drill pipes, and earth-moving drilling and mining, etc., can solve problems such as affecting the working efficiency of loading and unloading drill pipe devices, and achieve the advantages of shortening the turning radius, strong maneuverability, and reducing the telescopic stroke. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

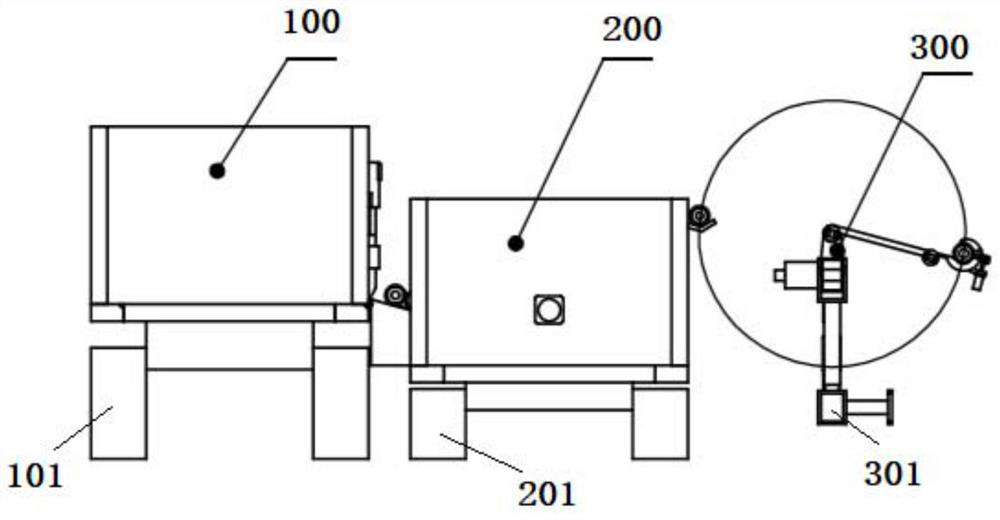

[0081] This embodiment provides an automatic loading and unloading drill pipe device for a coal mine tunnel drilling machine, which is characterized in that it includes a rod storage car 100 , a rod adding car 200 and a manipulator 300 .

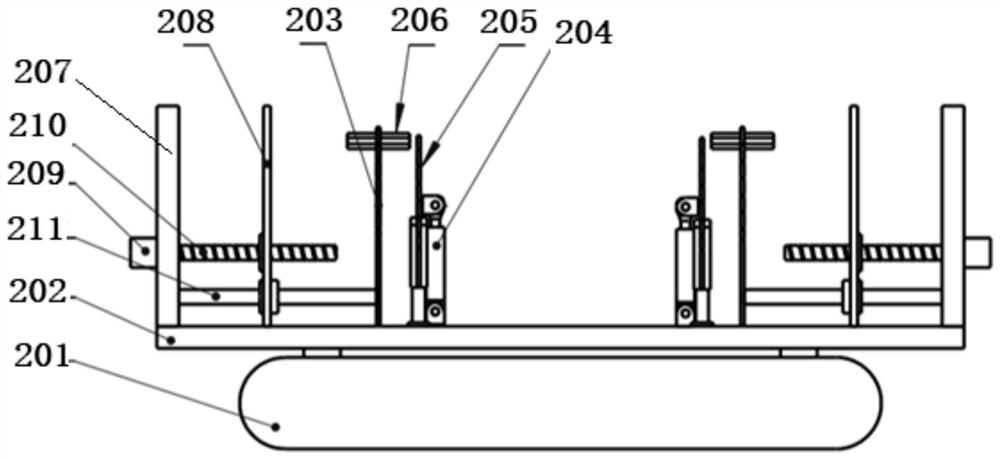

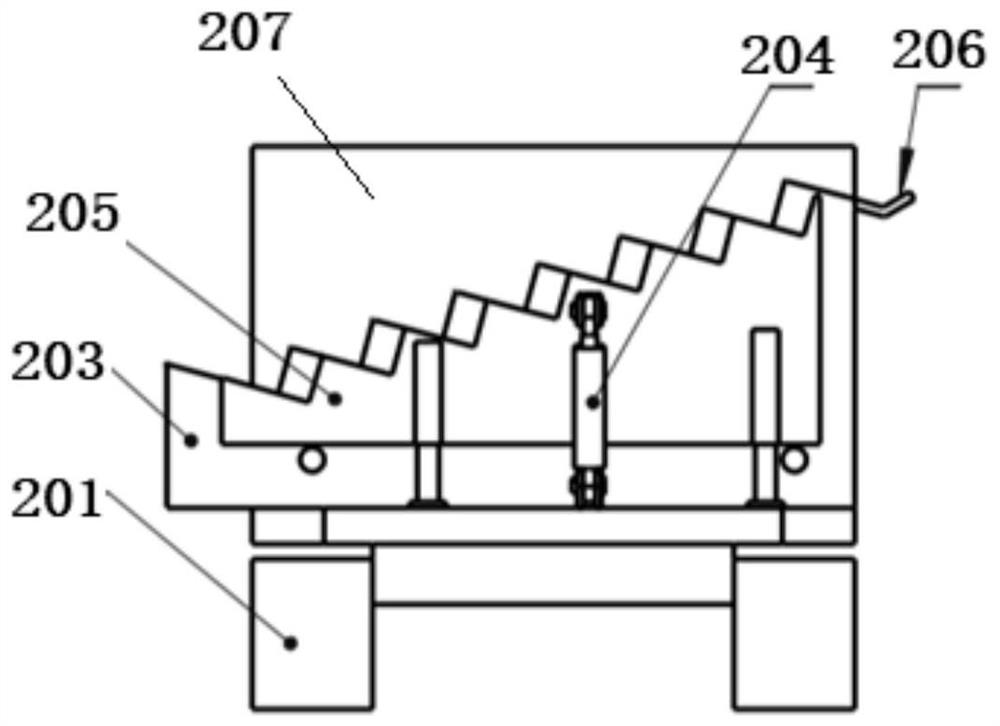

[0082] The pole-adding vehicle 200 includes a first crawler belt assembly 201 , a horizontal first base plate 202 fixed on the first crawler belt assembly 201 , and two parallel and opposite vertical stepped fixing plates 203 fixed on the first base plate 202 , two vertical first oil cylinders 204 fixed on the first bottom plate 202 and located between the two stepped fixed plates 203, two parallel opposite and step-shaped oil cylinders respectively fixed on the two first oil cylinders 204 The fixed plate 203 is parallel to the stepped movable plate 205 and the first oil cylinder 204 can drive the stepped movable plate 205 to reciprocate vertically up and down; The highest step of the fixed plate 203 is connected with a V-shaped bracket 206;...

Embodiment 2

[0107] This embodiment provides a control method for an automatic loading and unloading drill pipe device for a coal mine tunnel drilling rig, including:

[0108] Step 1, the process of adding rods:

[0109] Step 1.1, arrange the rod storage car, the rod adding car and the manipulator installed on the drilling rig in sequence, arrange the manipulator so that the rotating beam is parallel to the V-shaped bracket, and adjust the fourth oil cylinder to rotate the gripper to reach the position of the V-shaped bracket It can also rotate to the position of the holder to place the drill pipe while grabbing the drill pipe;

[0110] Step 1.2, control the contraction of the second oil cylinder in the rod storage car to make the rotating bottom plate tilt to the lateral gap side, and the drill pipe automatically rolls to the step groove of the first step of the stepped fixed plate of the rod adding car;

[0111] Step 1.3, control the first oil cylinder to drive the stepped movable plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com