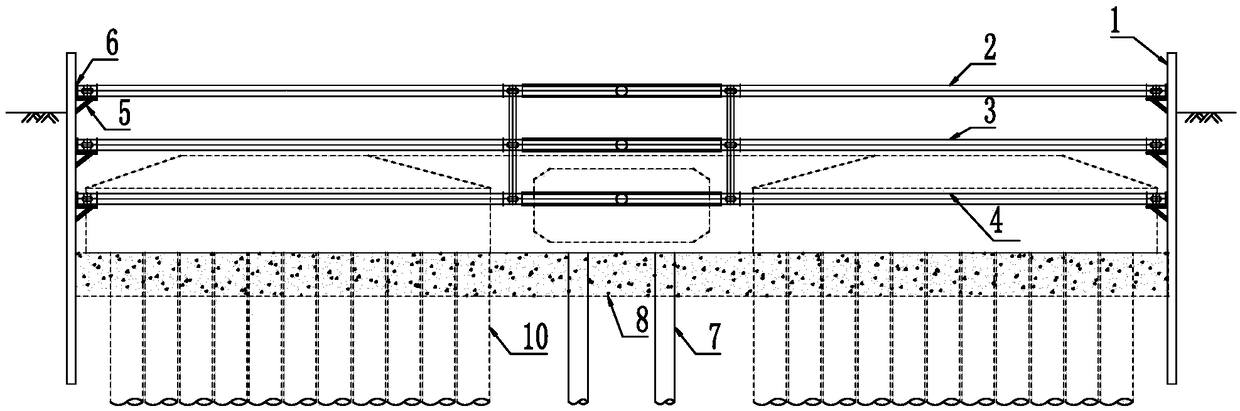

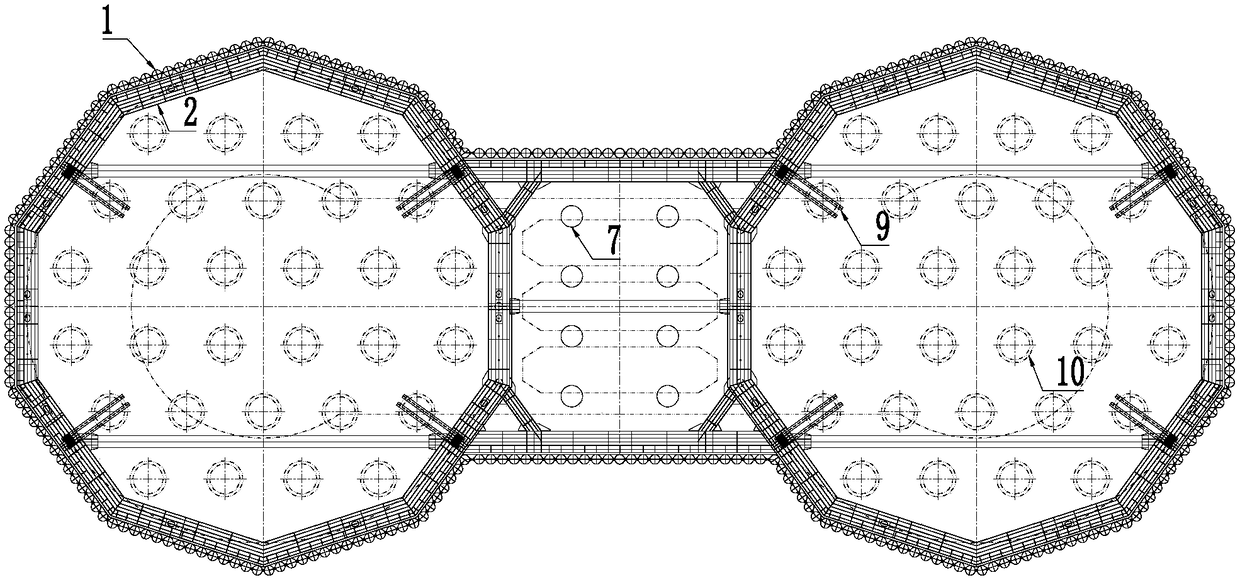

Fore shaft steel pipe pile cofferdam and construction method thereof

A construction method and technology of steel pipe piles, which are applied in infrastructure engineering, construction, etc., can solve the problems of steel pipe pile instability, complicated process, and large limitations, and achieve high overall rigidity, good economy, and improved pressure bearing effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

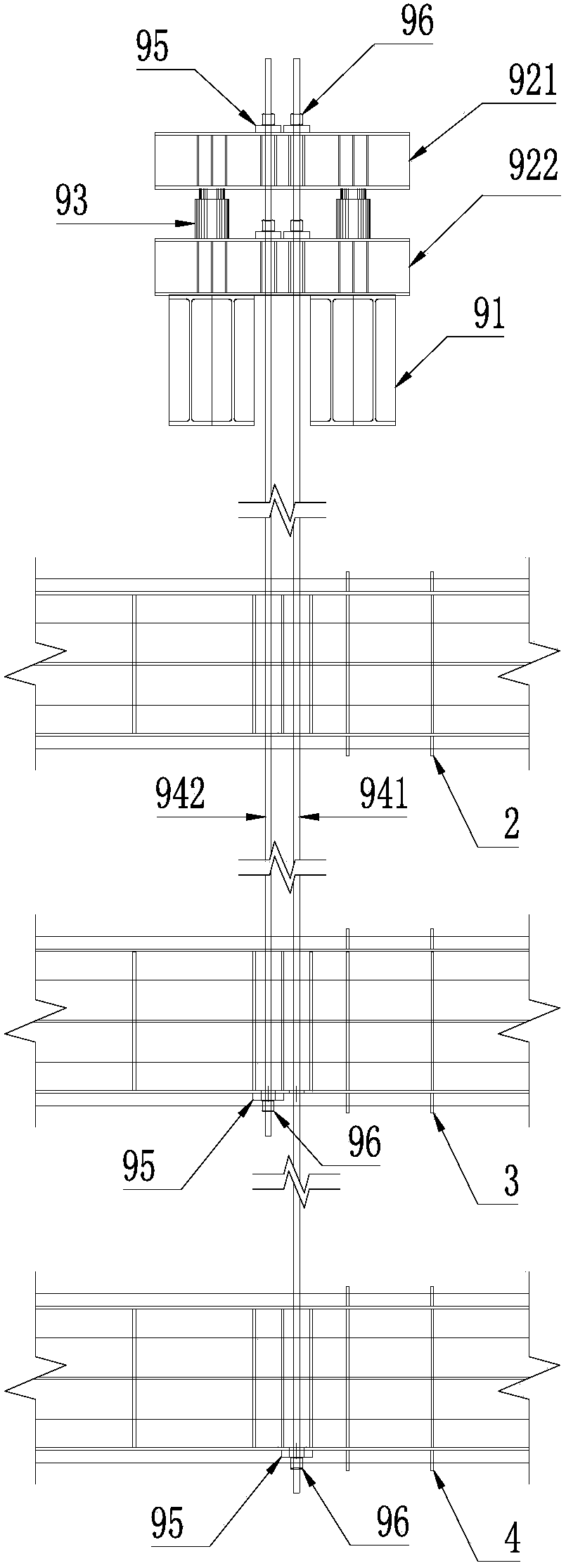

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: The template includes a plurality of wooden templates, each wooden template includes a side plate 141 and two webs 142 arranged in parallel, one side of the side plate 141 is close to the inner support 2, and the two webs 142 are vertically arranged on the side On the other side of the board 141, gaps are left between adjacent wooden formworks.

Embodiment 2

[0057] Embodiment 2: the template is a geotextile 17, and the concrete pad 6 also includes a plurality of steel bars 16, and the two ends of each steel bar 16 are respectively fixedly connected with the bottom of the internal support and the locking steel pipe pile 1, and the plurality of steel bars 16 are all located at The bottom of the geotextile 17 serves as a supporting structure for the geotextile 17 .

[0058] The embodiment of the present invention also provides a construction method of the interlocking steel pipe pile cofferdam. The method includes the following steps: assembling the inner support, inserting and driving the interlocking steel pipe pile 1 during simultaneous construction, passing a plurality of connecting pieces through the inner support, The bottom of each connector is connected with the bottom of the inner support that needs to be lowered to ensure that multiple connectors are installed at the bottom of the inner support that needs to be lowered, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com