Film paving device applied to ceramic tile seam beautification

A film laying device and beautifying seam technology, which is applied in the field of beautifying seams of ceramic tiles, can solve the problems of uneven application, time-consuming and laborious, material overflow, etc., and achieve the effect of improving work efficiency, improving transmission efficiency, and ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

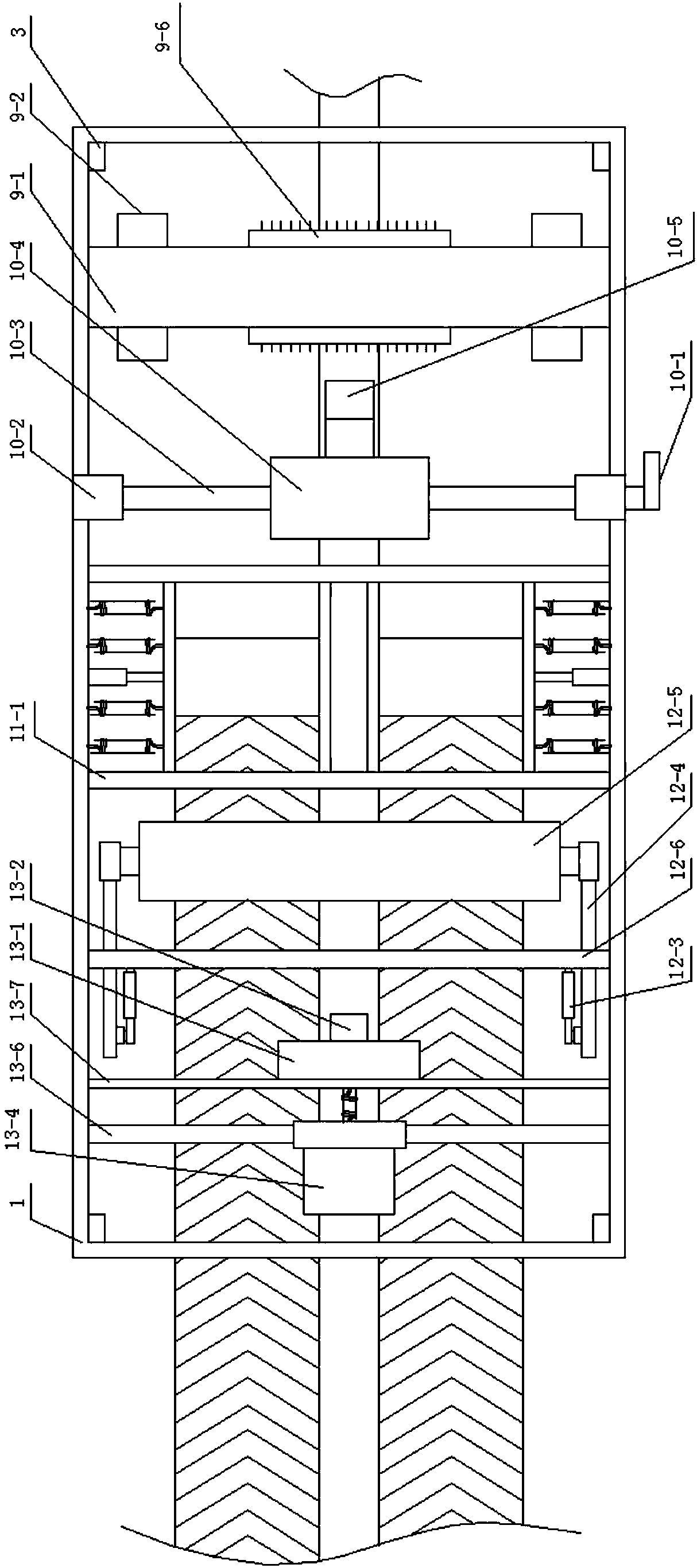

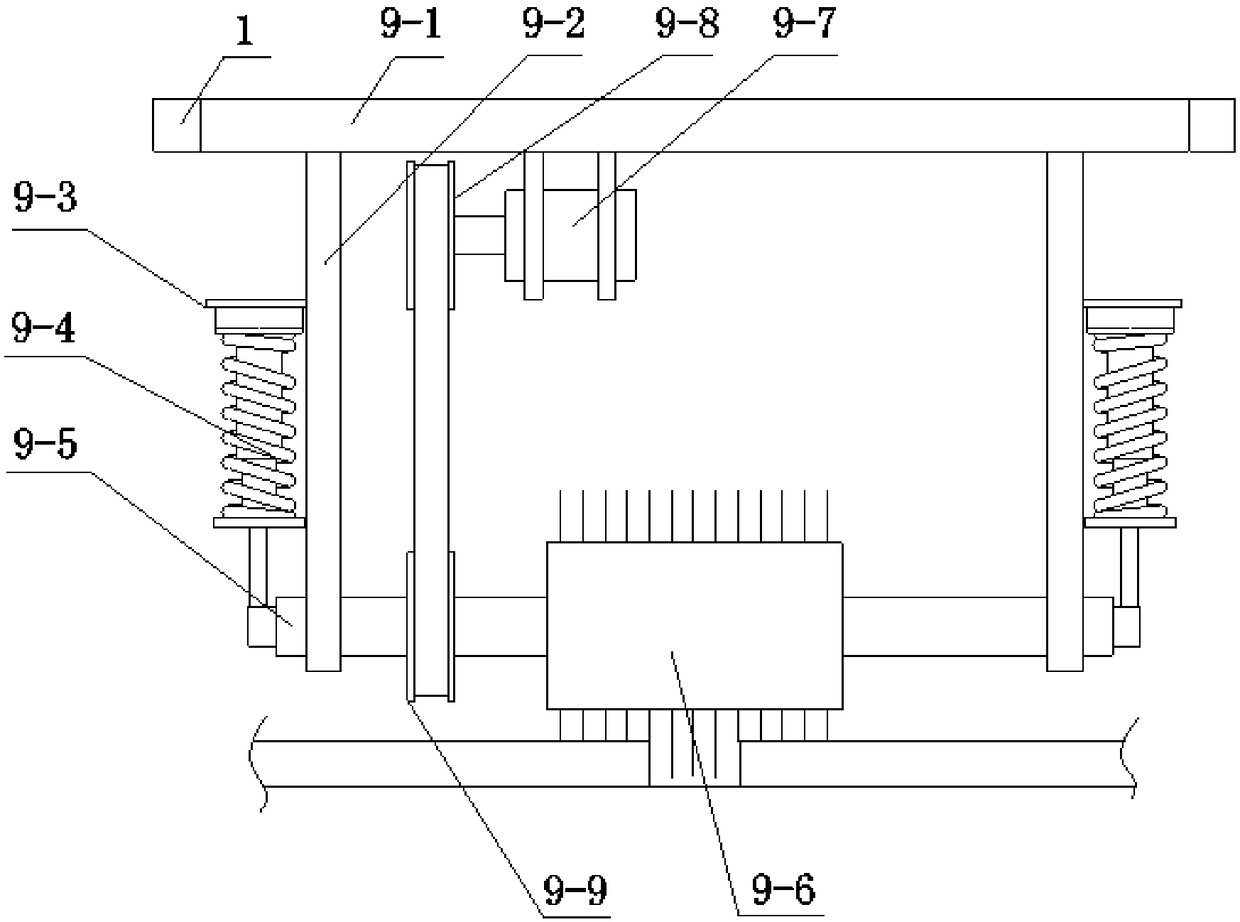

[0033] Embodiment 1: A film laying device applied to beautiful seams of ceramic tiles, including: consisting of a limiting device 11 and a pressing device 12,

[0034] The limiting device 11 includes: a limiting slide rail 11-1, a fixed plate 11-2, a casing 11-3, a No. 1 moving plate 11-4, a limiting column 11-5, a fixed column 11-6, two No. mobile plate 11-7, masking paper tube 11-8 and limit plate 11-9, two limit slide rails 11-1 placed side by side are arranged on the front and rear side walls of frame 1, and the lower end surface of frame 1 front and rear side walls A fixed plate 11-2 is vertically arranged, and a casing 11-3 is arranged on the inner wall of the fixed plate 11-2, and the upper ends of the No. 1 mobile plate 11-4 and the No. 2 mobile plate 11-7 pass through the slider and the limit slide rail 11-1 is connected, and the No. 1 mobile plate 11-4 outer wall is provided with limit column 11-5, and limit column 11-5 cooperates with sleeve pipe 11-3, and one end o...

Embodiment 2

[0037] Embodiment 2: A film laying device applied to the beautification of ceramic tiles, installed in the beautification device, the beautification device is provided with a limiting device 11, and a pressing device 12 is arranged behind the limiter 11.

Embodiment 3

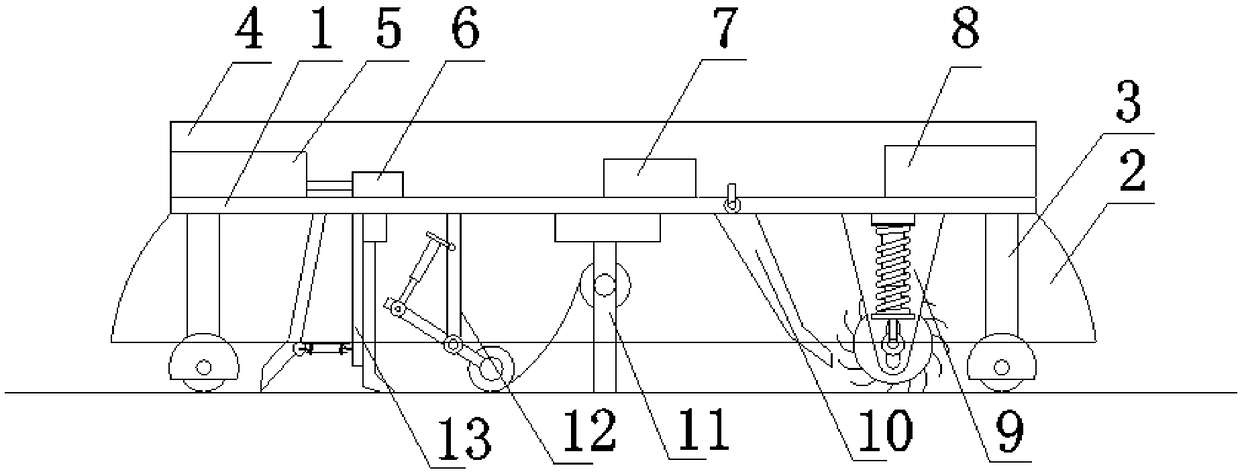

[0038] Embodiment 3: The beautifying device includes: frame 1, lower casing 2, pulley 3, upper casing 4, beautifying agent storage box 5, power pump 6, air pump 7, battery 8, cleaning device 9, sootblower Device 10 and beauty joint agent injecting and setting device 13,

[0039] The upper end surface and the lower end surface of the frame 1 are respectively provided with an upper casing 4 and a lower casing 2, and the four corners of the lower end surface of the frame 1 are provided with pulleys 3;

[0040] The lower end surface of the frame 1 is sequentially provided with a beautifying agent injecting and shaping device 13, a soot blowing device 10 and a cleaning device 9 from left to right;

[0041] The upper casing 4 is provided with a beauty joint agent storage box 5 , a power pump 6 , an air pump 7 and a storage battery 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com