Textile fabric defect detection model and training method and application thereof

A training method and point detection technology, applied in the field of deep learning and computer vision, can solve problems such as low accuracy, poor real-time performance, and lack of versatility, and achieve the effects of improving accuracy, fast detection speed, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

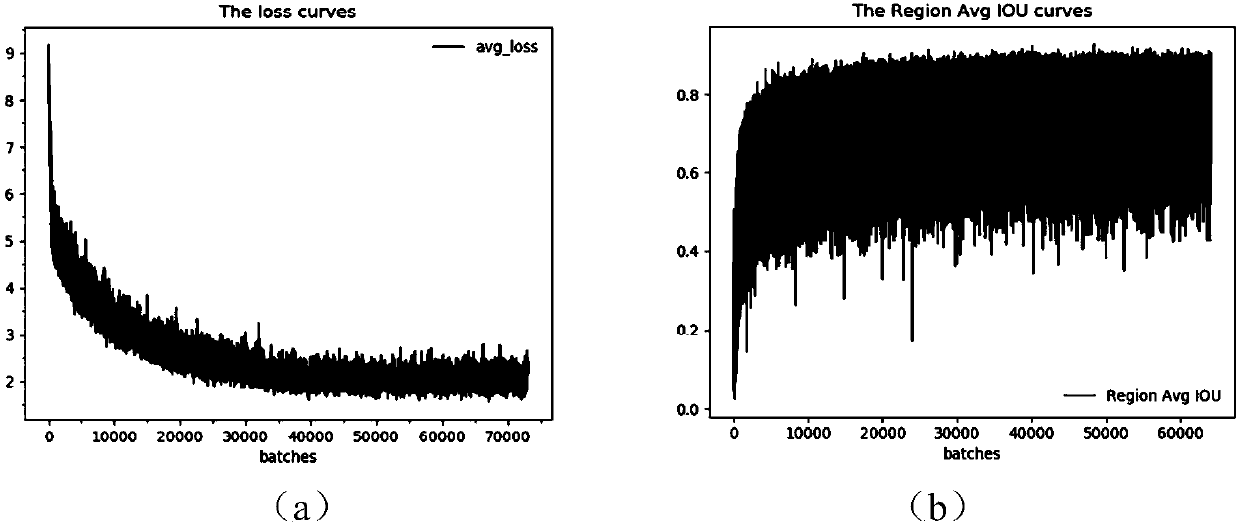

[0062] The convolutional neural network used in the present invention can accept the input of any pixel image in principle, but considering that an image with too large pixels will cause small defects to be distorted after resize, and an image with too small pixels will cause some features to be extracted. , the reference pixel given by the official is 416×416. In embodiment 1 of the present invention, a pixel size of 1216×1020 is adopted in consideration of the large scope of one-time identification of cloth and the adequacy of feature extraction.

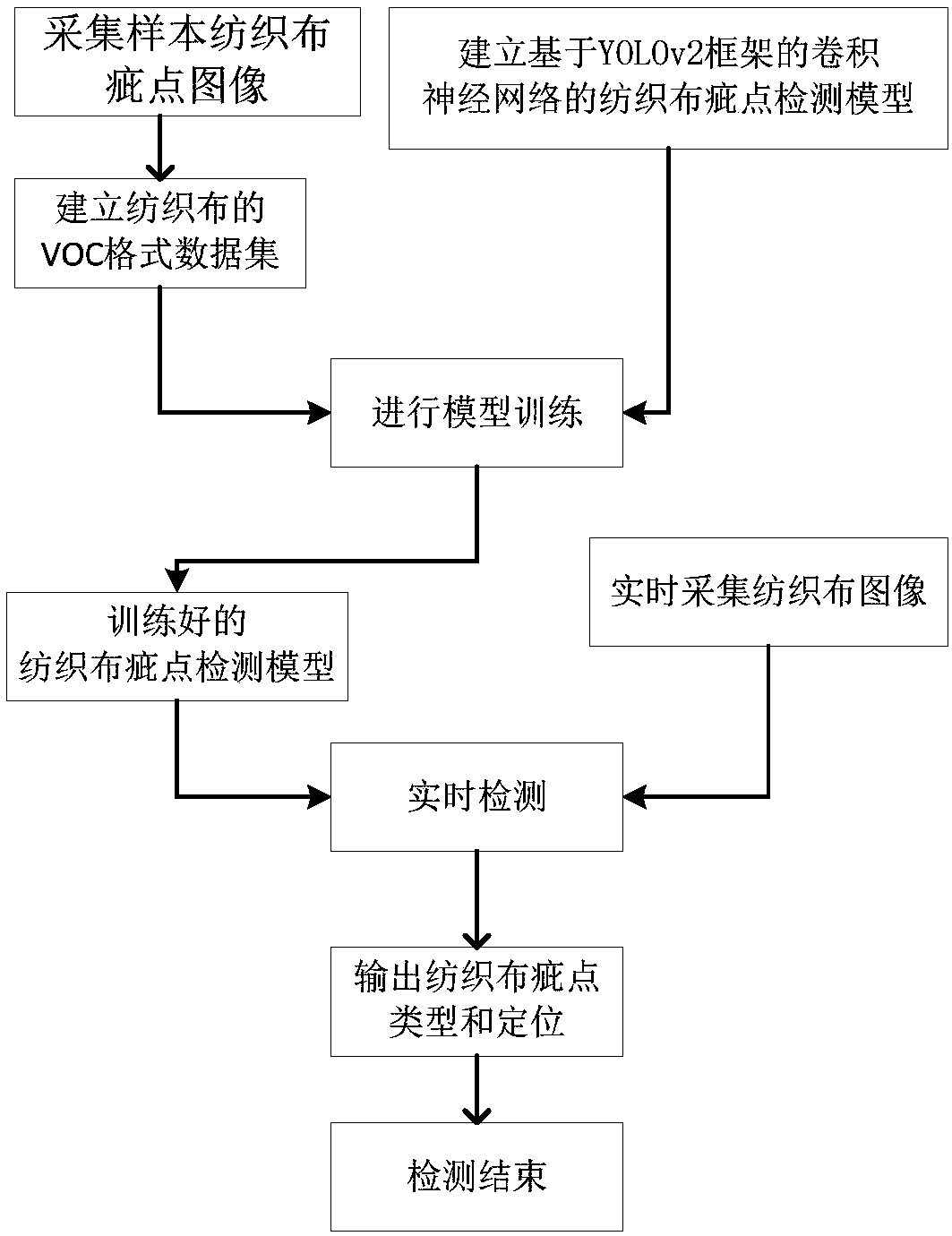

[0063] An application of a textile defect detection model, including:

[0064](1) Use an industrial camera to collect and select images containing six types of defects including warp breaks, weft breaks, holes, foreign matter, oil stains, and creases as sample textile defect images. The sample textile defect images are in jpg format with a resolution of 96dpi The three-channel color image with a pixel size of 1216×1020; create two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com