Circularly polarized F-P resonant cavity antenna with high gain and low RCS

A resonant cavity antenna, circular polarization technology, applied in the direction of antenna, antenna grounding switch structure connection, electrical components, etc., can solve the problems of increased manufacturing cost, complex antenna feed structure, low gain, etc., to achieve the effect of simplifying the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

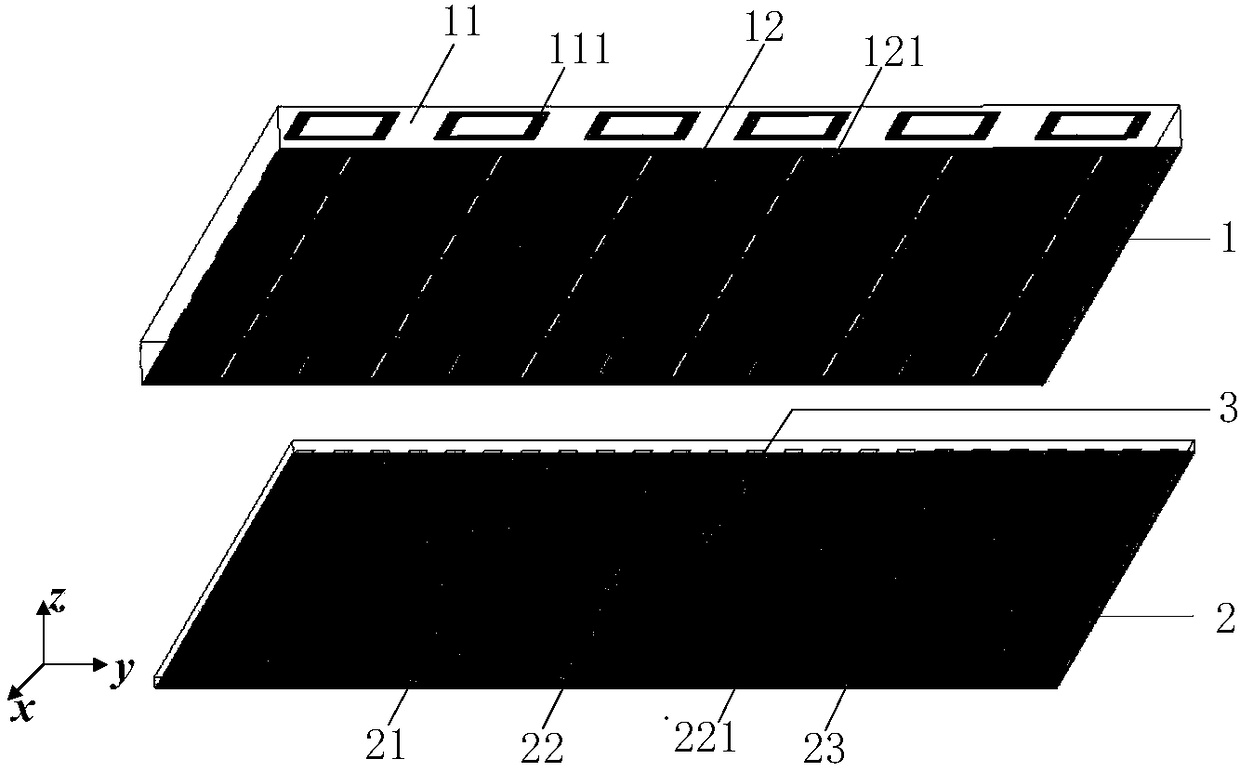

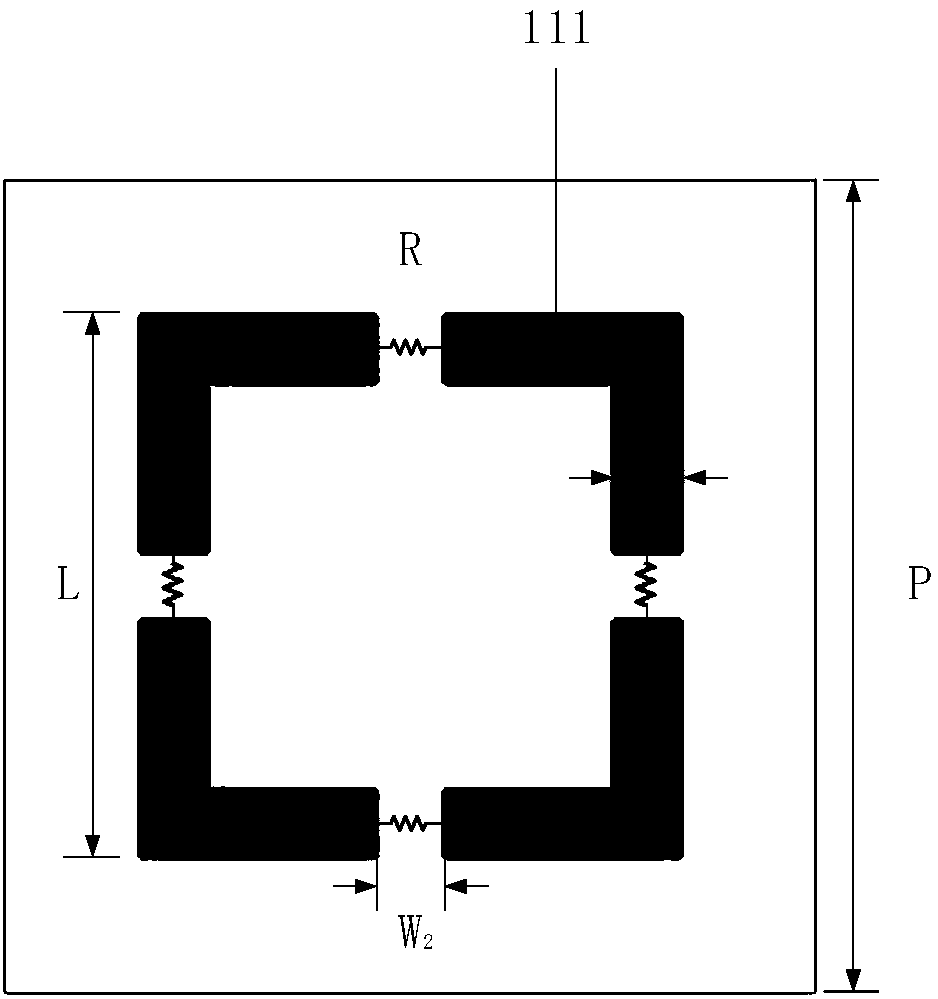

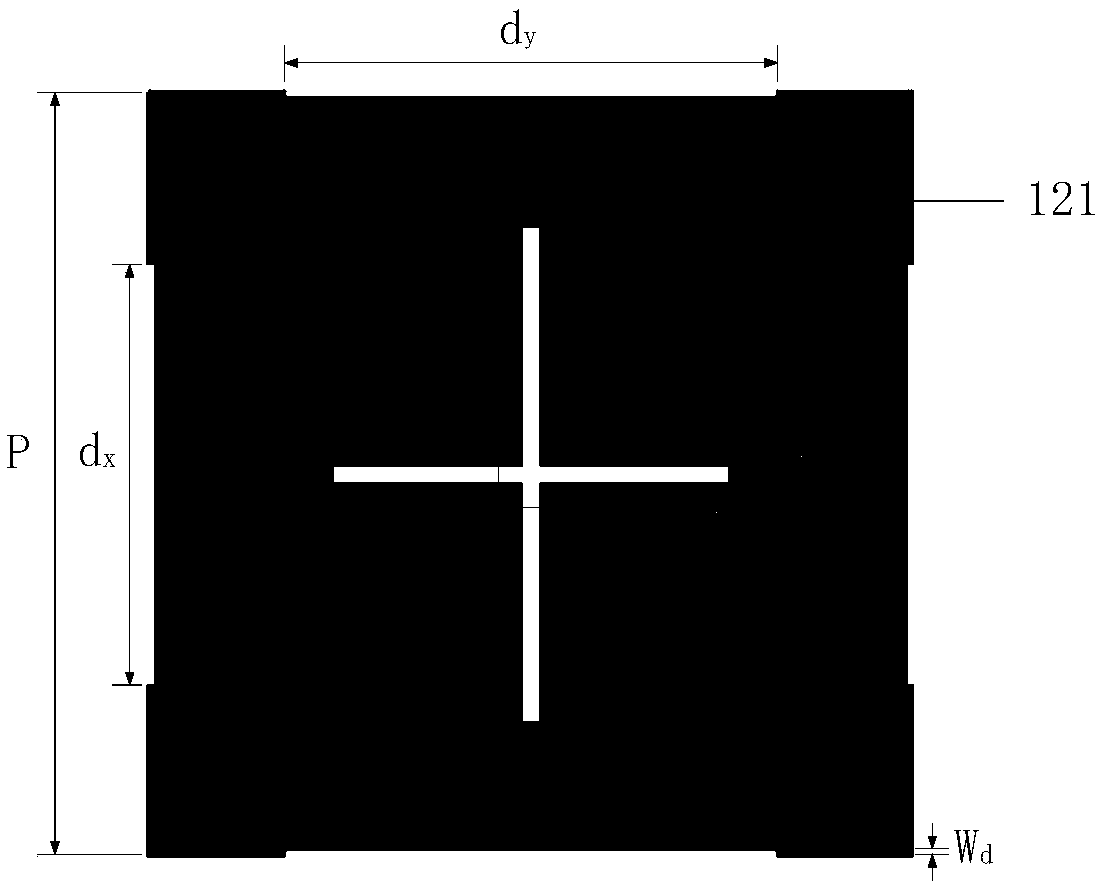

[0031] refer to figure 1 , the present invention includes an upper dielectric board 1 and a lower dielectric board 2, the upper dielectric board 1 has a wave-absorbing surface 11 printed on its upper surface, and a partially reflective surface 12 printed on its lower surface; the wave-absorbing surface 11, A structure of 6×6 wave-absorbing units 111 is periodically arranged. The wave-absorbing unit 111 adopts a square ring structure with a rectangular gap in the middle of the four sides. Each gap is loaded with a resistor to convert electromagnetic wave energy into heat energy, thereby achieving RCS reduction; the partially reflective surface 12 adopts a structure in which 6×6 partially reflective surface units 121 are periodically arranged, and the partially reflective surface unit 121 adopts a cross-shaped groove with different lengths in the center and four sides with The square patch structure with rectangular slots, due to the different lengths of the cross-shaped slots, ...

Embodiment 2

[0039] The structure of this example is the same as that of Example 1, and only the following parameters have been adjusted:

[0040] The distance H=11mm between the lower surface of the upper dielectric plate 1 and the upper surface of the lower dielectric plate 2, the length of the square ring of the absorbing unit 111 is L=7mm, and the ring width is W 1 =0.5mm, the size of the rectangular notch is W 1 ×W 2 =0.5mm×1.5mm, resistance impedance R=50Ω, the length of the long groove of the cross-shaped groove of the partially reflective surface unit 12 is S x =7mm, the length of the short slot is S y =5mm, groove width is W s = 0.2mm, the rectangular grooves arranged on the four sides of the partially reflective surface unit 12 include a pair of rectangular long grooves and a pair of rectangular short grooves, and the length of the rectangular long grooves is d y =6mm, the length of the short rectangular slot is d x =5mm, groove width is W d =0.05mm, the length of the strip...

Embodiment 3

[0042] The structure of this example is the same as that of Example 1, and only the following parameters have been adjusted:

[0043] The distance H=13mm between the lower surface of the upper dielectric plate and the upper surface of the lower dielectric plate, the length of the square ring of the absorbing unit 111 is L=9mm, and the ring width is W 1 = 1.5mm, the size of the rectangular notch is W 1 ×W 2 =1.5mm×0.5mm, resistance impedance R=200Ω, the length of the long groove of the cross-shaped groove of the partially reflective surface unit 12 is S x =9mm, the length of the short slot is S y =7mm, slot width is W s =0.4mm, the rectangular grooves arranged on the four sides of the partially reflective surface unit 12 include a pair of rectangular long grooves and a pair of rectangular short grooves, and the length of the rectangular long grooves is d y =11mm, the length of the short rectangular slot is d x =10mm, slot width is W d =0.2mm, the length of the strip metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com