Method and device for predicting and controlling currents of a single current sensor of a permanent magnet synchronous motor

A permanent magnet synchronous motor, current prediction technology, applied in the direction of single-phase motor control, motor generator control, control of electromechanical transmission devices, etc., to achieve the effect of servo control, simplify hardware system, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

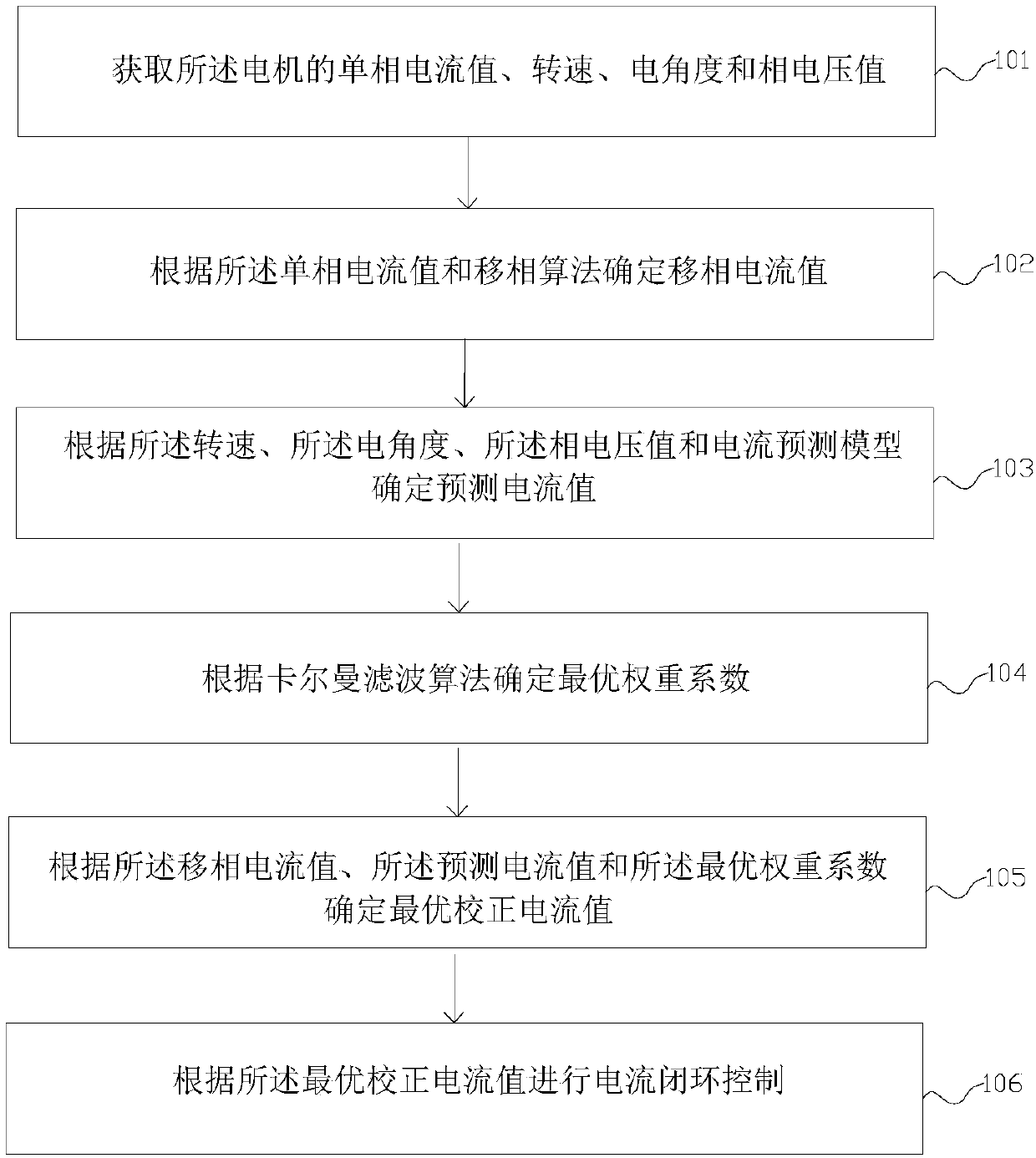

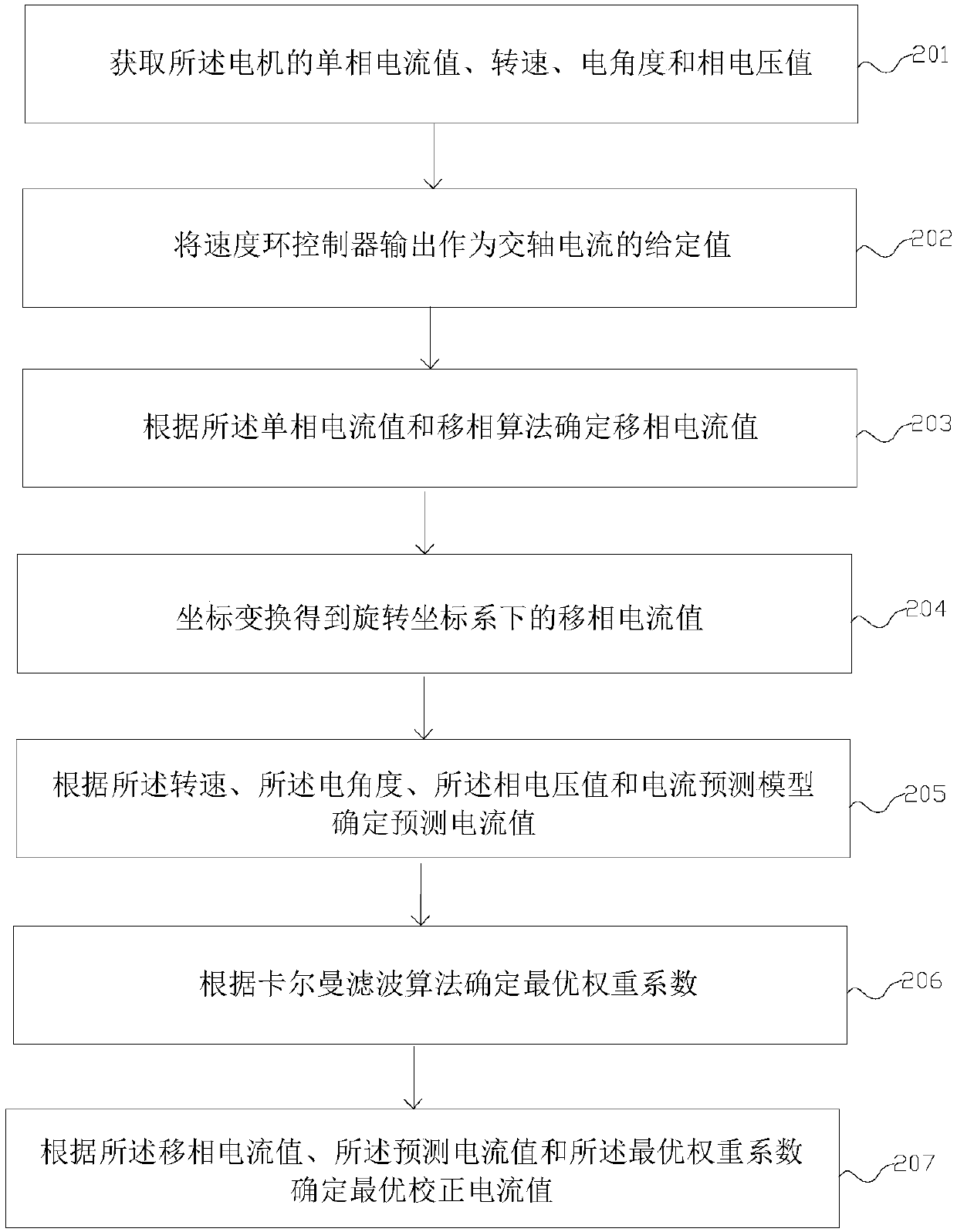

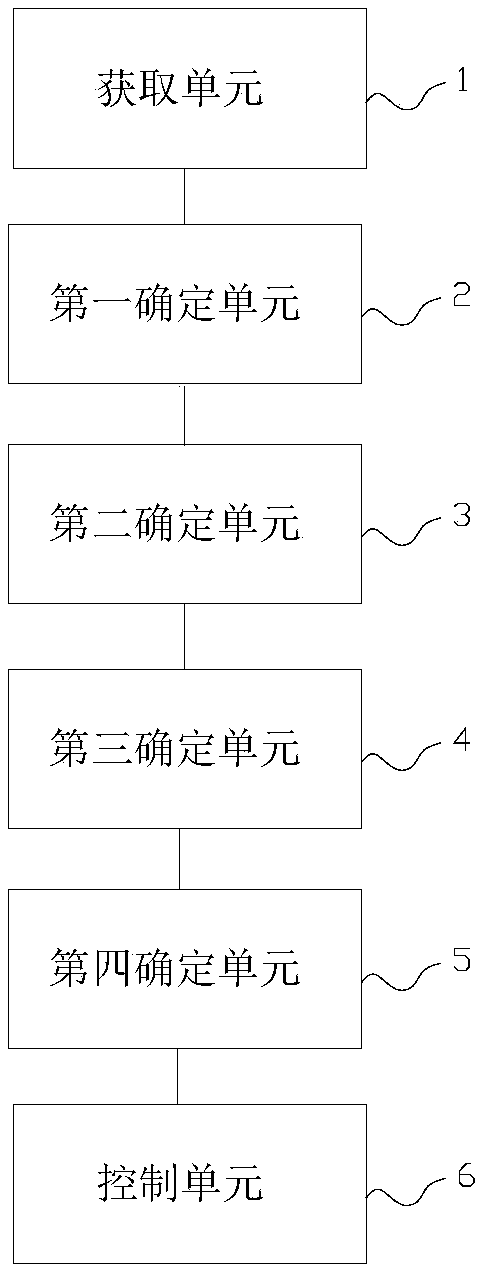

[0036] The following description and drawings illustrate specific embodiments of the invention sufficiently to enable those skilled in the art to practice them. The embodiments merely represent possible variations, individual components and functions are optional unless explicitly required, and the order of operations may be varied. Portions and features of some embodiments may be included in or substituted for those of other embodiments. The scope of embodiments of the present invention includes the full scope of the claims, and all available equivalents of the claims. Herein, various embodiments may be referred to individually or collectively by the term "invention", which is for convenience only and is not intended to automatically limit the scope of this application if in fact more than one invention is disclosed. A single invention or inventive concept. Herein, the term "comprises", "comprises" or any other variation thereof is intended to cover a non-exclusive inclusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com