Bean product granule production equipment

A technology for production equipment and bean products, which is applied in the field of bean product granule production equipment, to achieve the effects of reducing moisture, improving practicability, and reducing uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with embodiments. The present embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

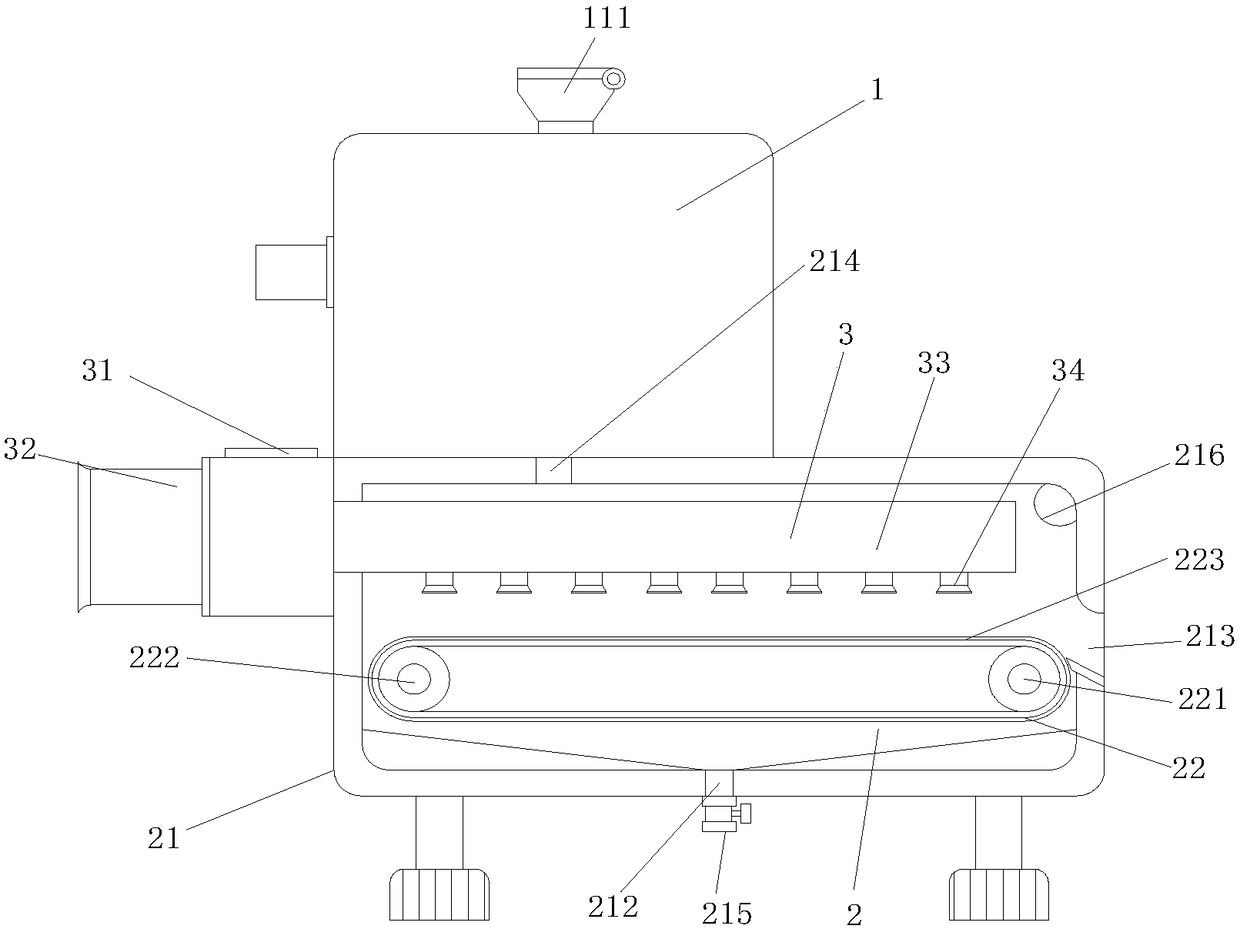

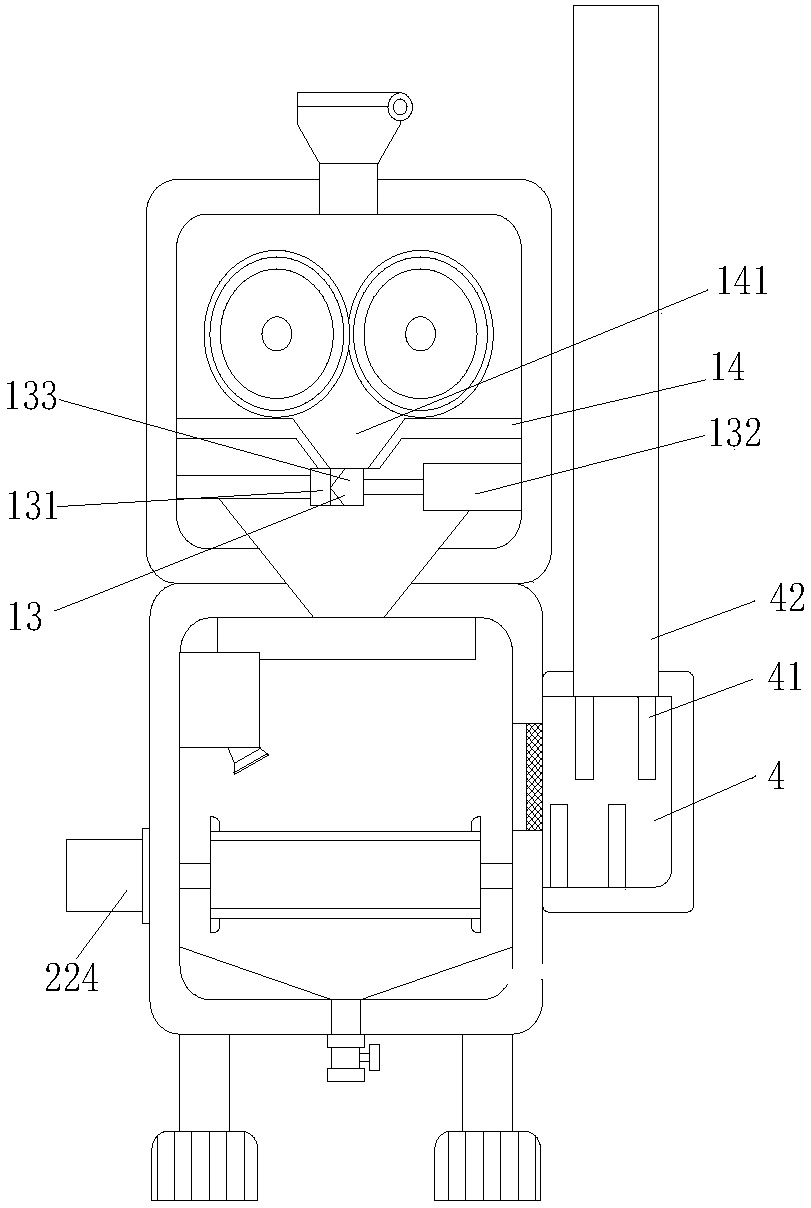

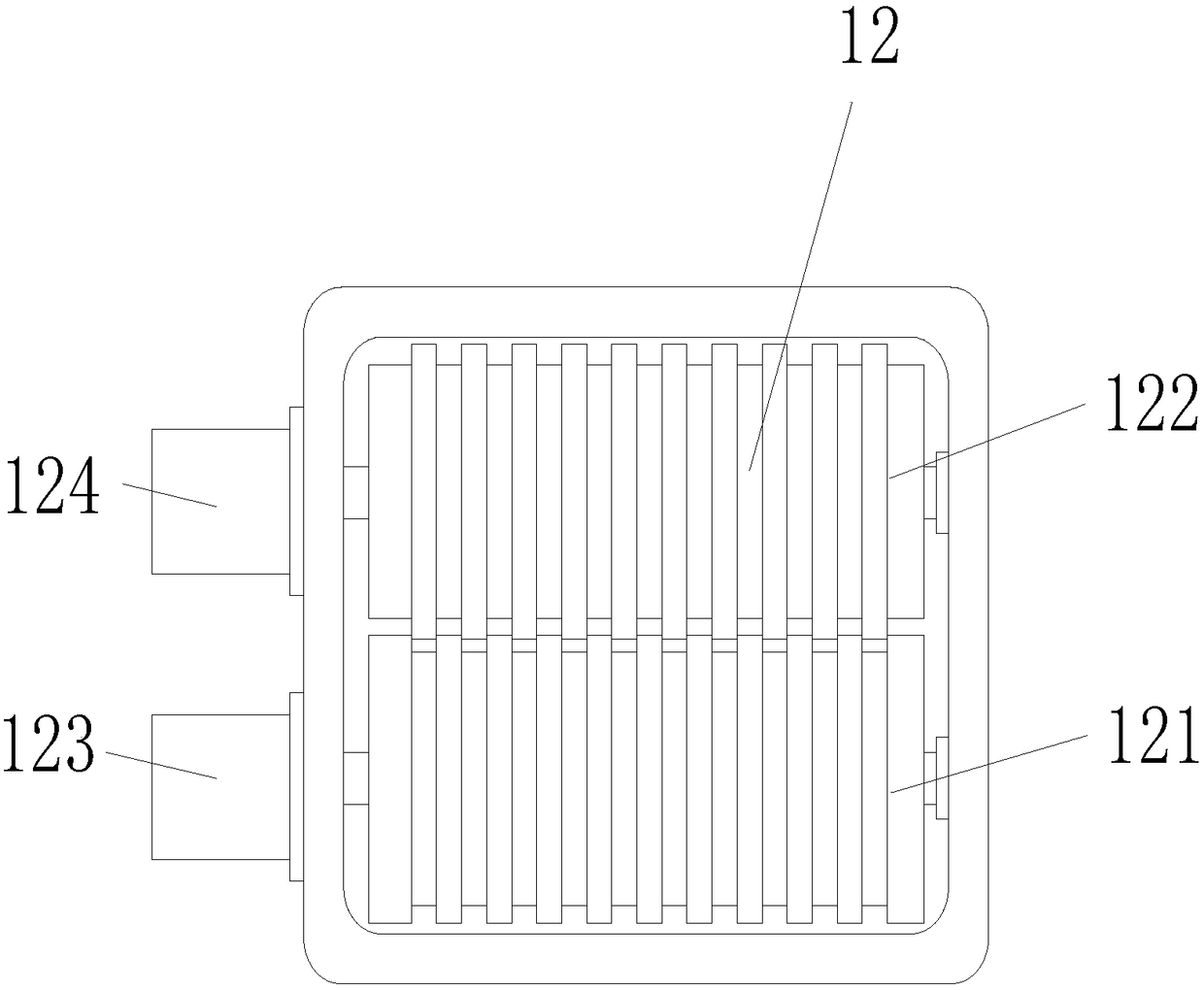

[0018] according to Figure 1-3 As shown, this embodiment provides a soy product pellet production equipment, including a granulating device 1, a conveying device 2 and a hot air system 3. The conveying device 2 includes an air drying bin 21 and a belt set on the air drying bin 21 Type conveying mechanism 22, the belt type conveying mechanism 22 includes a driving roller 221, a driven roller 222 and a transmission belt 223, the driving roller 221 and the driven roller 222 can be rotatably arranged on both side walls of the drying bin 21 Above, the active roller 221 is connected to the output shaft of the conveying motor 224 arranged on the outer side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com