Collodion cotton mop

A collodion mop and collodion technology, applied in the field of mops, can solve the problems of large weight and volume of the mop, inconvenient operation, and laborious squeezing, and achieve the effects of good extrusion effect, labor-saving operation and small number of settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

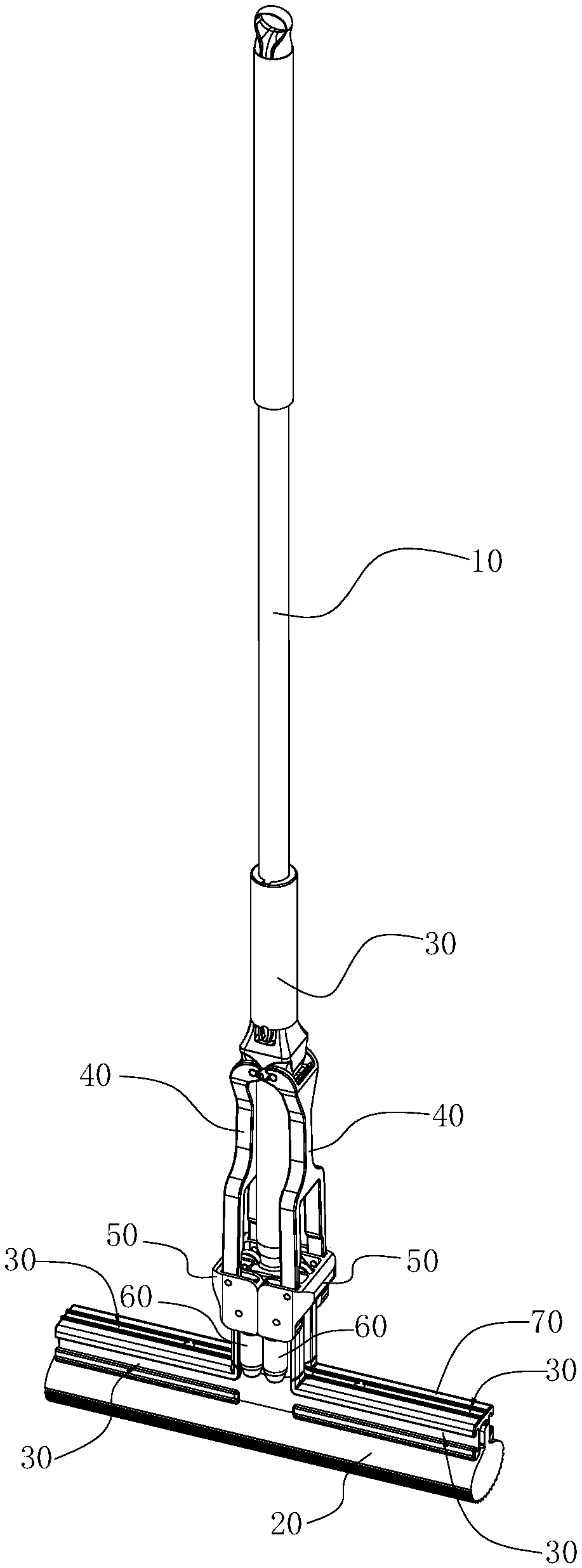

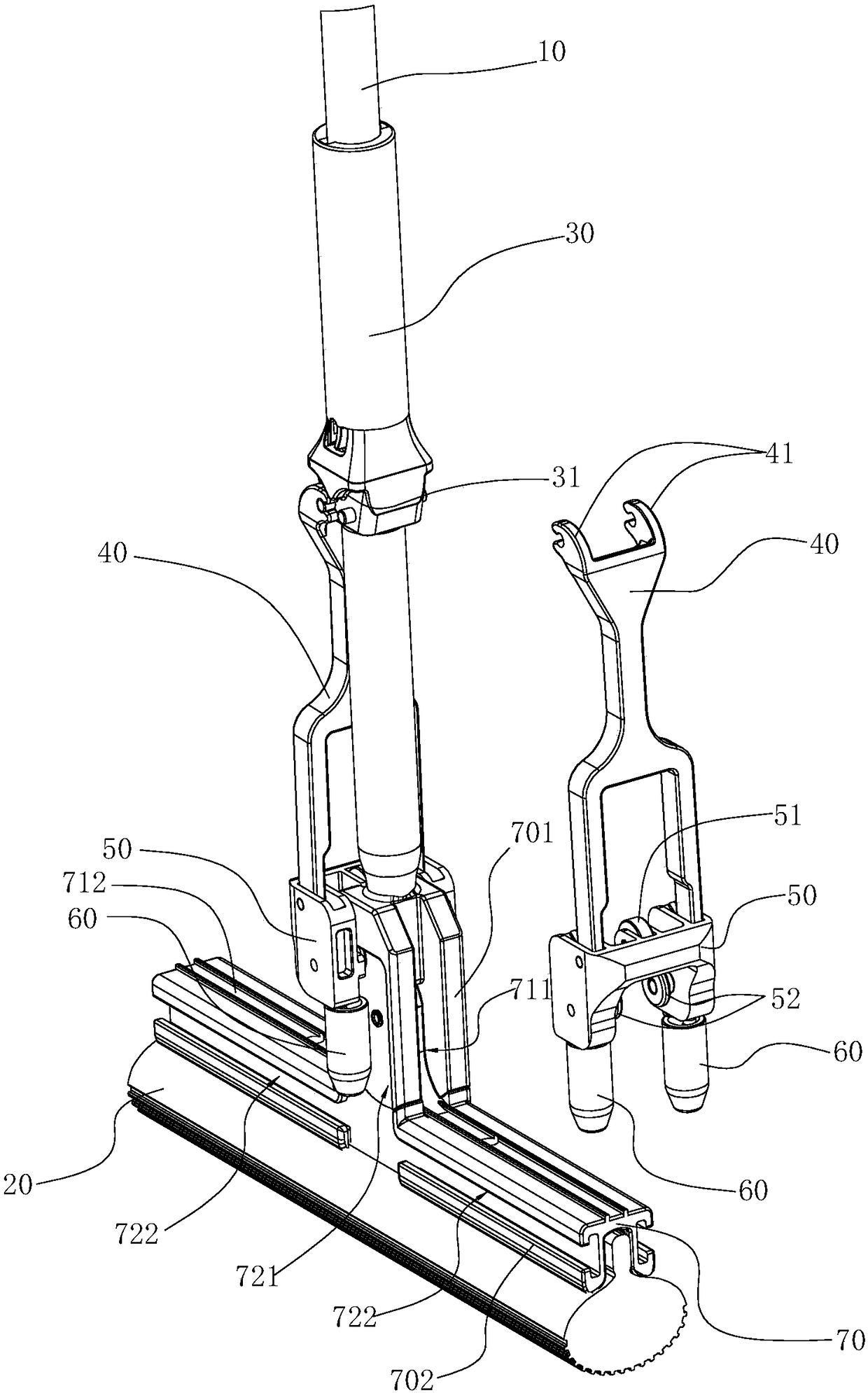

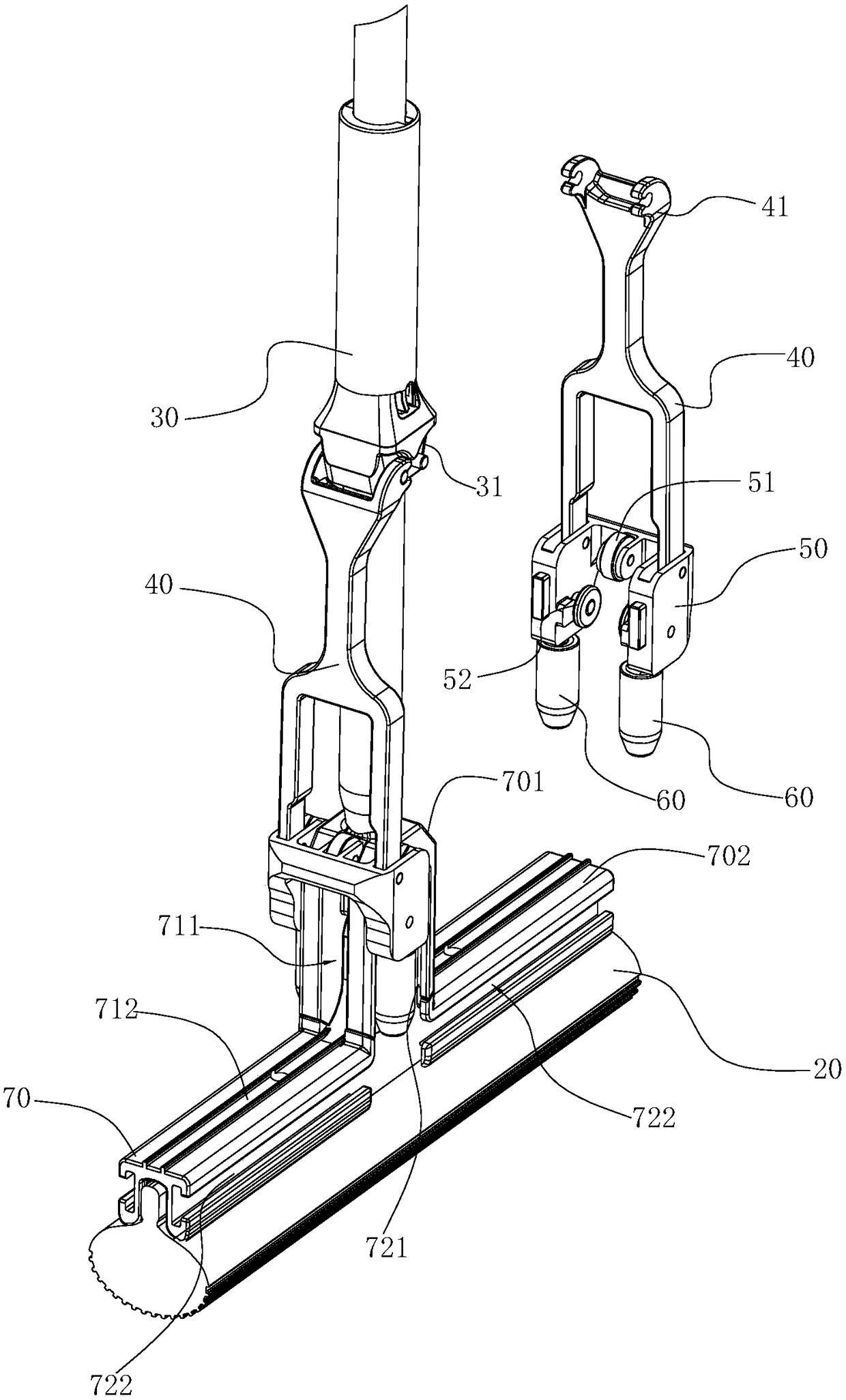

[0025] The collodion mop of the present invention, such as Figure 1-3 As shown, it includes a mop bar 10 , and is connected to a collodion 20 located at the bottom of the mop bar 10 , and the collodion 20 extends perpendicularly to the mop bar 10 . A driving member 30 is sleeved on the mop bar 10, and the driving member 30 can slide up and down along the length direction of the mop bar 10. The driving member 30 is connected with a connecting member 40, and the bottom end of the connecting member 40 is connected with a water squeezing roller for fixing The seat 50, the water squeezing roller 60 is fixed below the water squeezing roller fixing seat 50. That is, the squeezing roller 60 is connected to the driving member 30 through the squeezing roller fixing seat 50 and the connecting member 40 . The driving member 30 moves up and down along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com