CNC cutting tool condition detection method and system

A state detection and tool technology, applied in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as affecting the productivity of CNC equipment, inability to process at the same time, increasing processing time, etc., to facilitate in-depth analysis and convenience. The effect of manual intervention to improve equipment productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate those skilled in the art to understand the technical solution of this patent, the technical solution of this patent will be further described in the form of specific cases below.

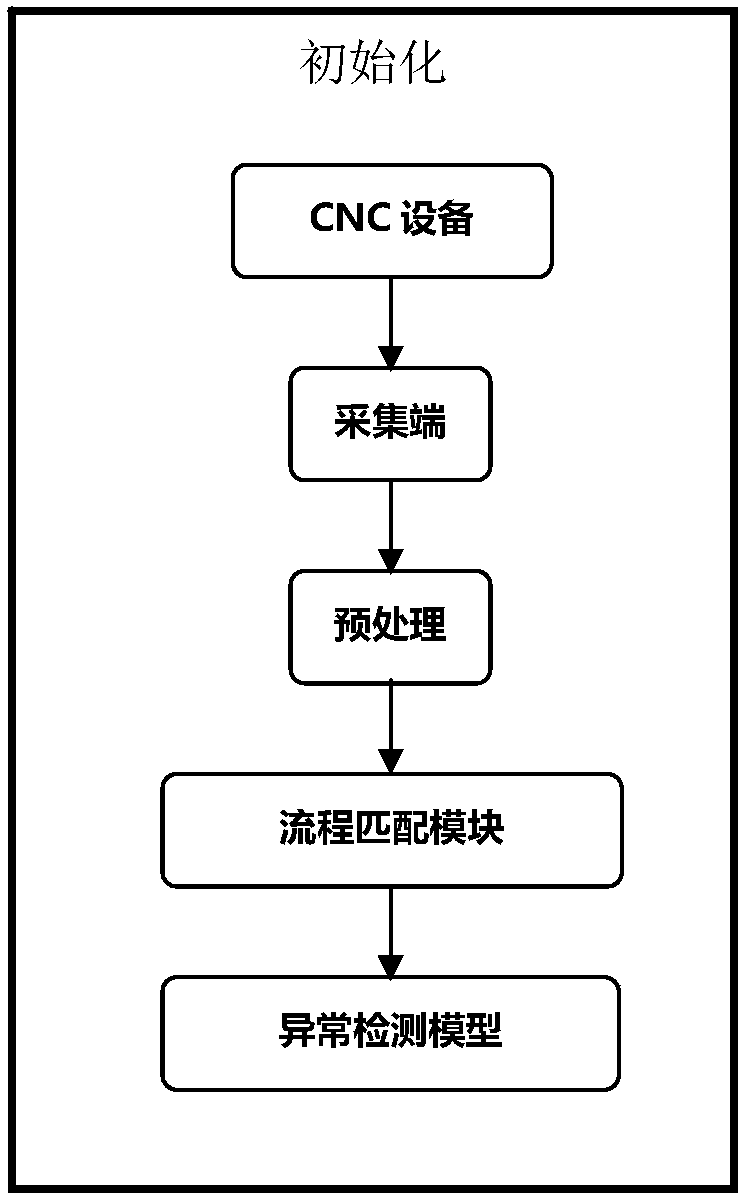

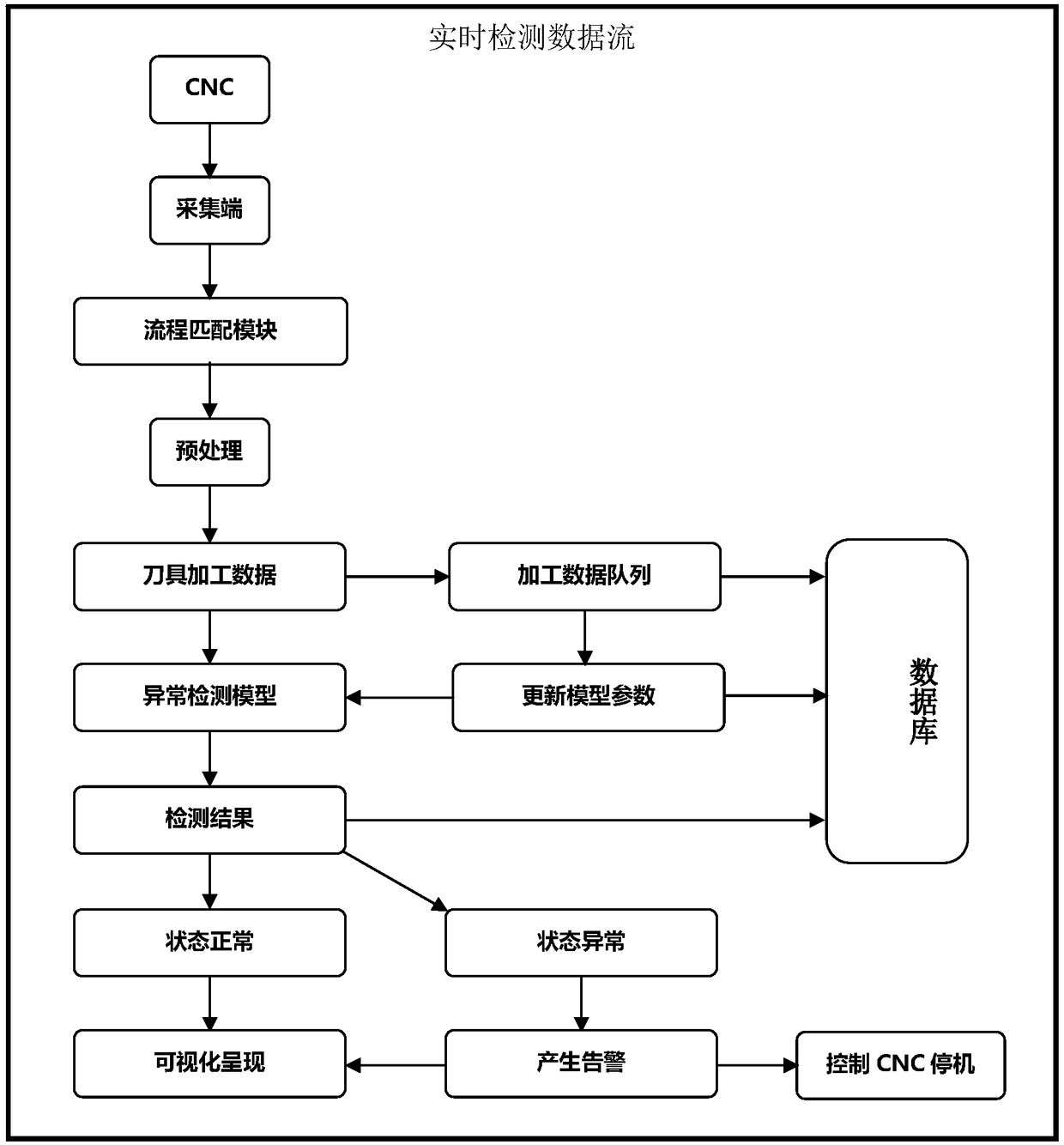

[0034] A CNC tool state detection method applied to a processing unit connected to a CNC device, comprising the following detection steps:

[0035] Collect the spindle state and machine tool state from the CNC equipment, the spindle state includes load and rotating speed, and the machine tool state includes processing state, tool number and temperature;

[0036] Determine the cutting tools and processing flow of CNC equipment;

[0037] According to the anomaly detection model generated in advance, detect whether the tool of the CNC equipment is abnormal;

[0038] When the tool state is found to be abnormal, stop the processing of the CNC equipment;

[0039] The generation method of the abnormal detection model is as follows:

[0040] Collect the data of spindle statu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com