Stretching type pneumatic artificial muscle

A pneumatic artificial muscle and pneumatic muscle technology, which is applied in the design of artificial muscles and connected by I-shaped joints, can solve the problems of single driving force direction and complex structure, and achieve the advantages of improving flexibility, making up for single direction and reducing frictional force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

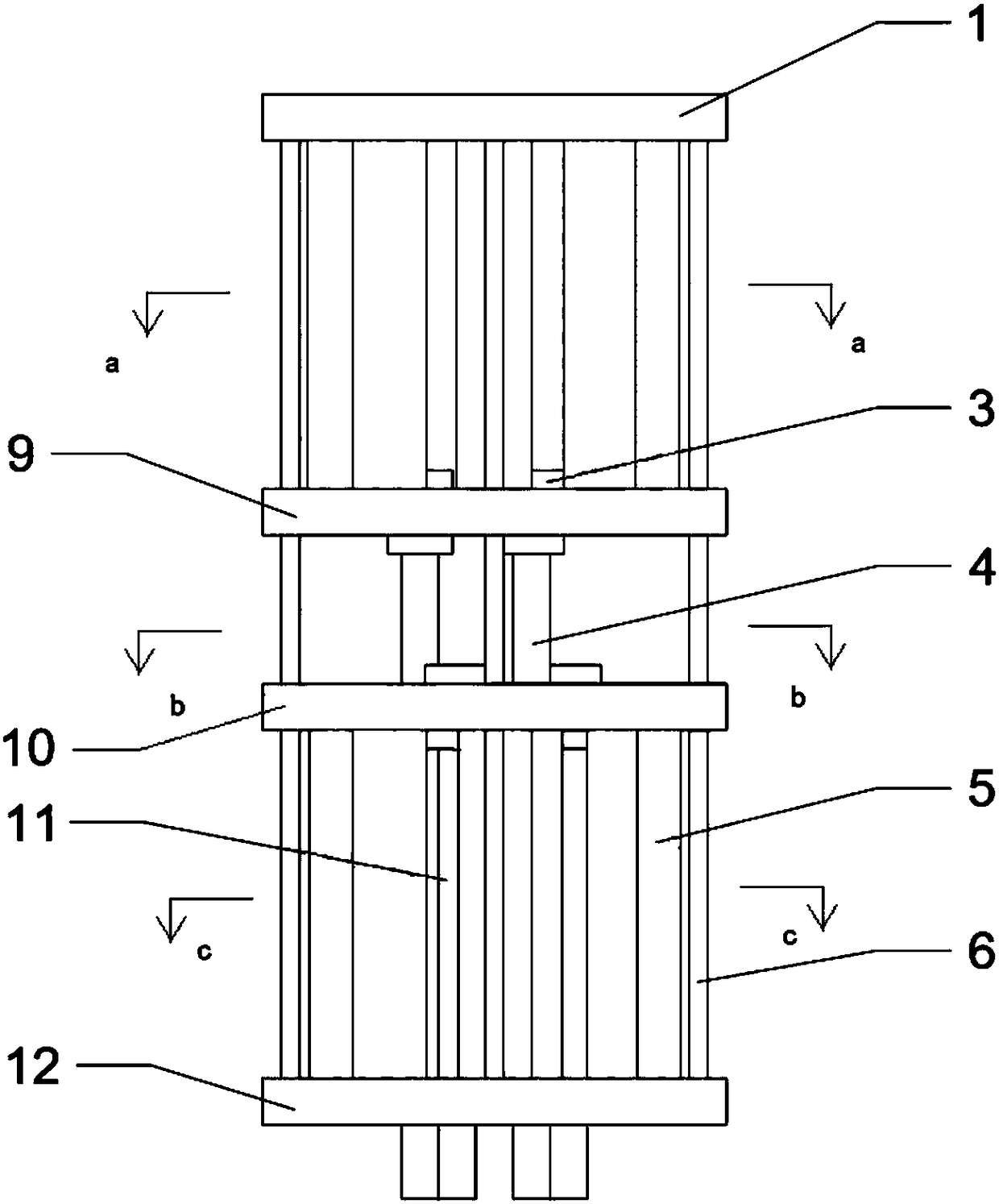

[0017] Below in conjunction with accompanying drawing and example the present invention is described in further detail. These drawings are all simplified schematic diagrams, which only schematically illustrate the rapid prototyping method of the present invention, and therefore only show the components related to the present invention.

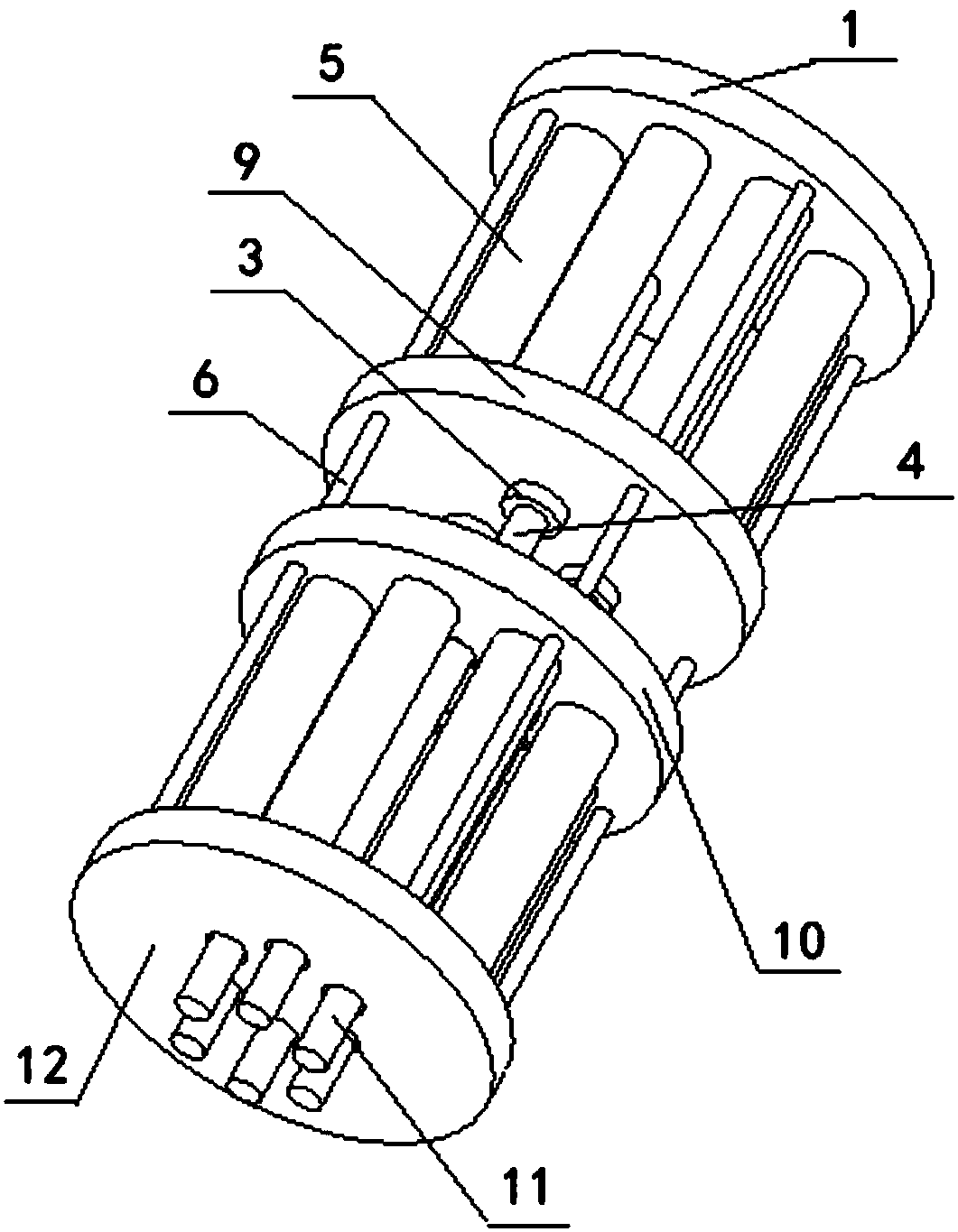

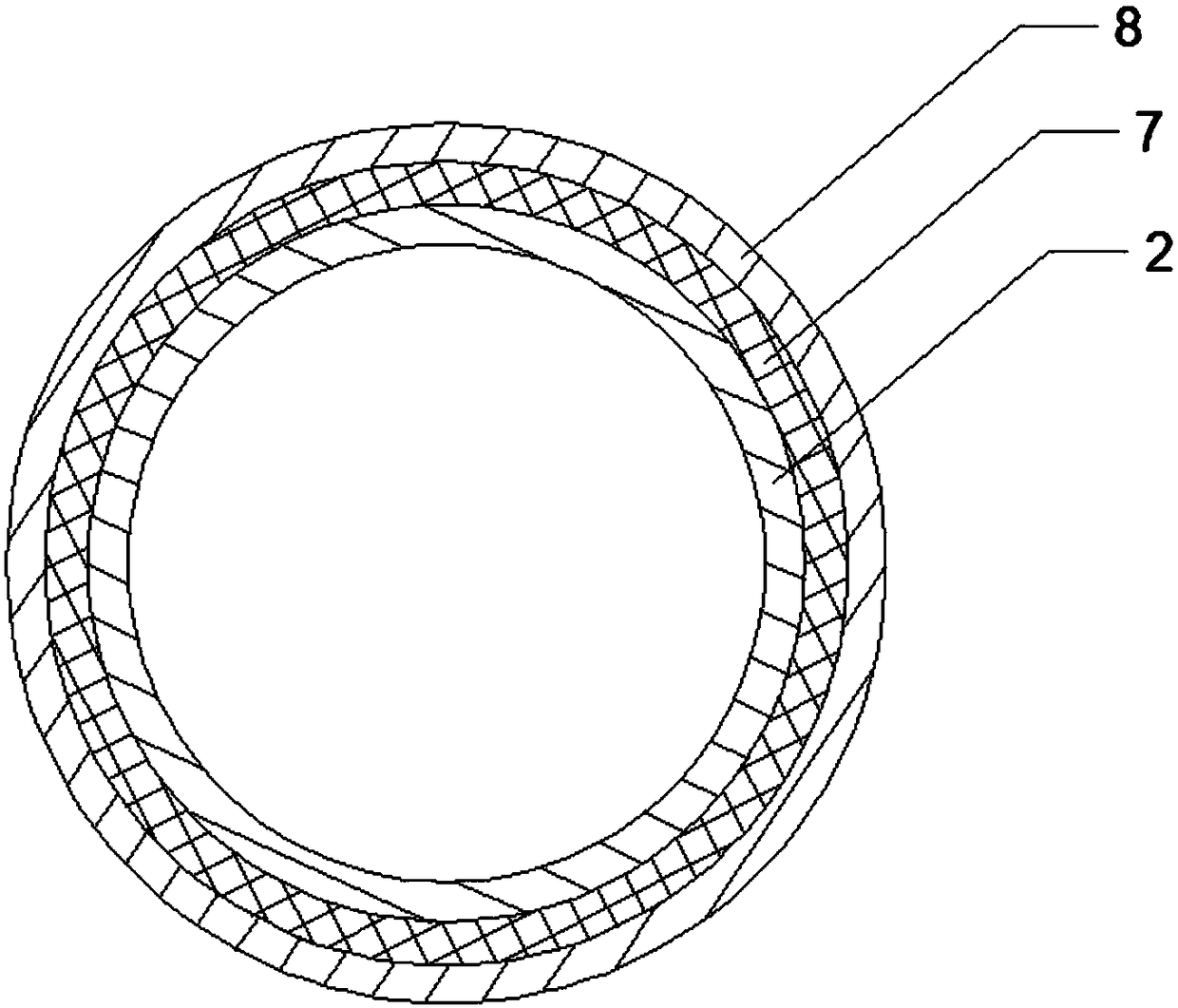

[0018] Such as figure 1 and figure 2 As shown, a stretching type pneumatic artificial muscle of the present invention includes an upper fixed plate 1, an I-shaped joint 3, an upper sliding shaft 4, a pneumatic muscle 5, a fixed rod 6, an upper moving plate 9, and a lower moving plate 10, Lower sliding shaft 11, lower fixed disk 12. Described fixed rod 6 outer surfaces are smooth, and two ends have screw thread, and one end connects upper fixed disc 1, and the other end connects lower fixed disc 12, and four fixed rods 6 and upper fixed disc 1, lower fixed disc 12 form a fixed structure. The pneumatic muscle 5 at the upper end is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com