Split type clutch brake

A brake and split technology, applied in manufacturing tools, presses, etc., can solve the problems affecting the service life of forging equipment, uneven clutch connection, poor braking effect, etc., to reduce the difficulty of installation and debugging, smooth connection, and reduce vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

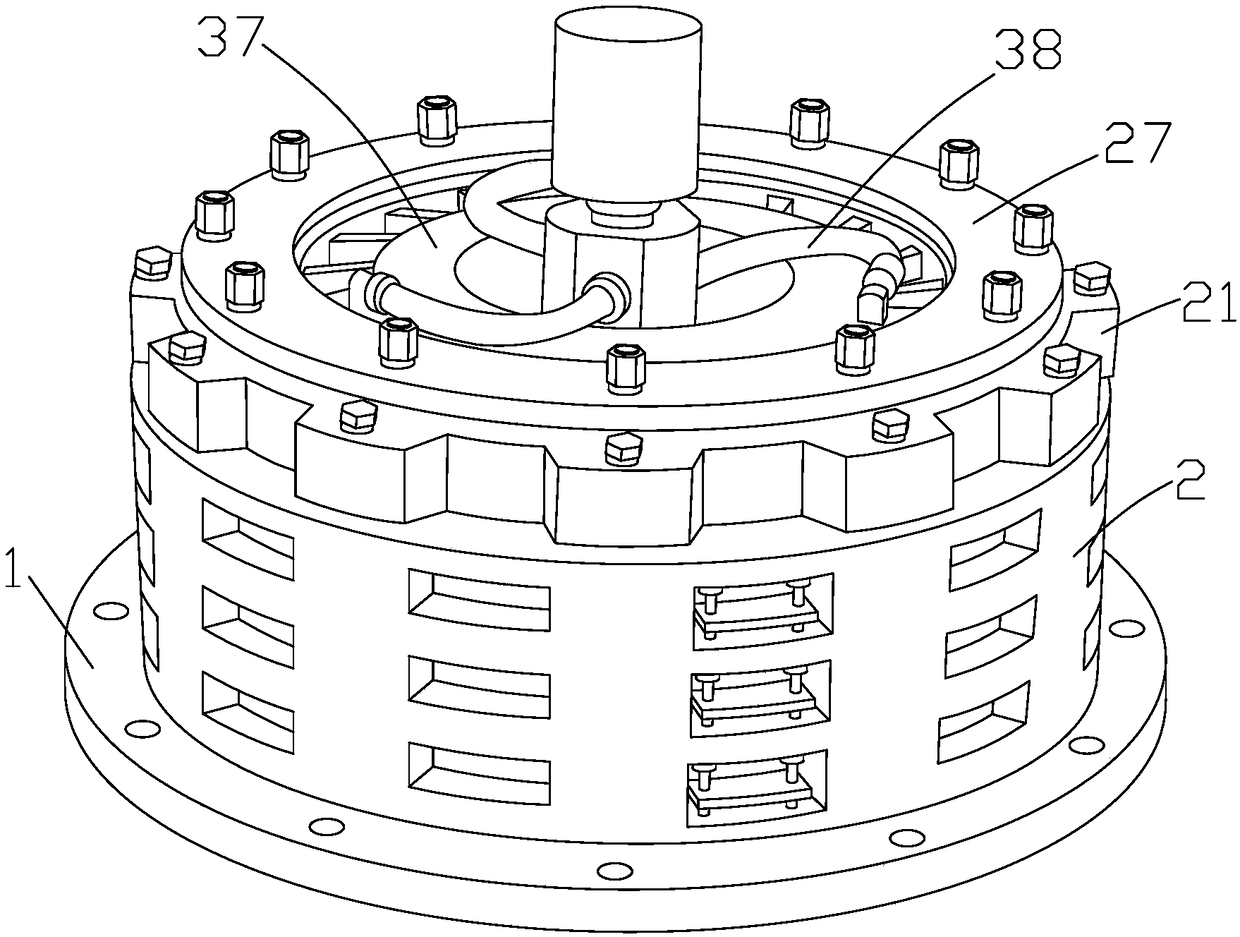

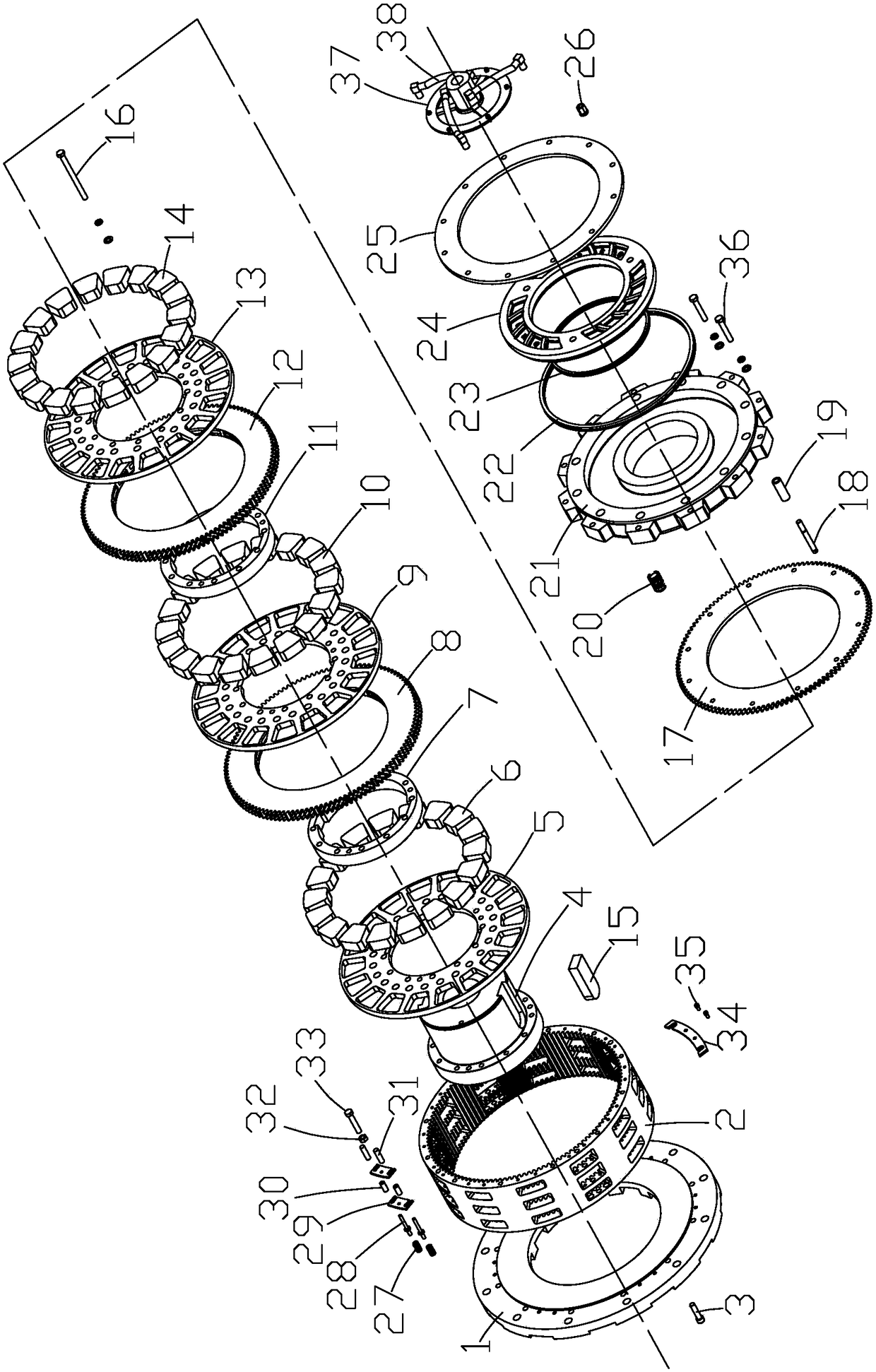

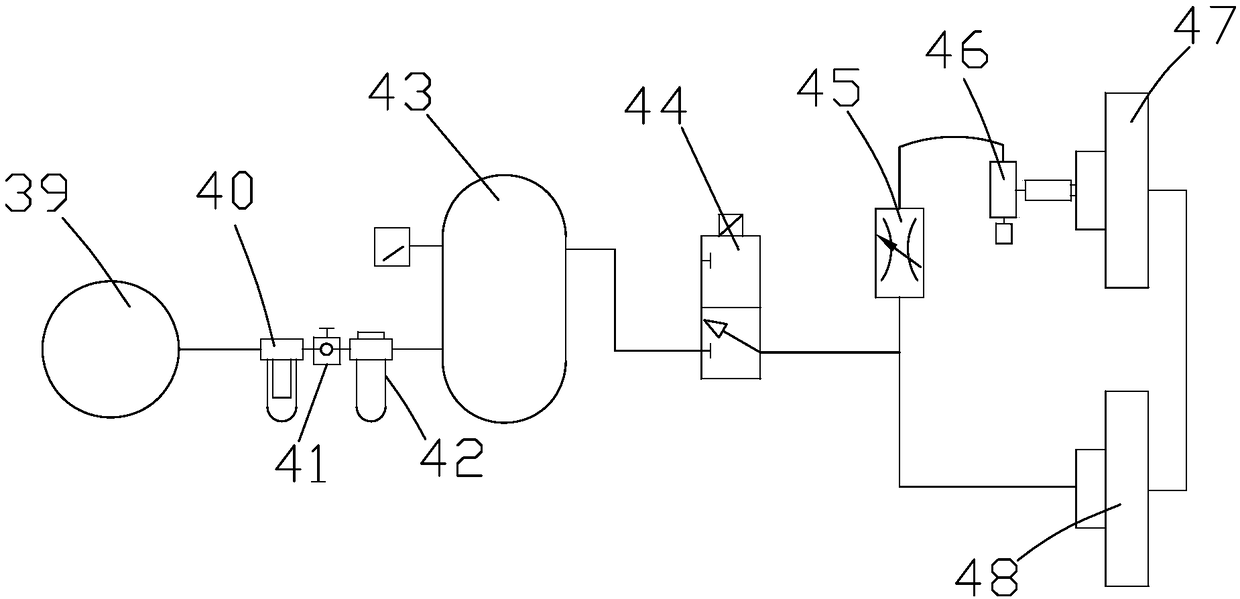

[0027] like Figure 1 to Figure 3 As shown, the split clutch brake of the present invention includes a brake 48 and a clutch 47. The brake 48 is connected to the bed through a positioning ring, the clutch 47 is connected to the flywheel, and the clutch 47 is connected to the brake 48 through the transmission shaft and the air circuit control system. The brake 48 and clutch 47 all include chassis 1, body gear 2, shaft hub 4, first friction assembly, second friction assembly, third friction assembly, cylinder assembly and air intake disc 37, chassis 1 is connected to the body by chassis screws and spring washers 3 Gear 2, the body gear 2 is provided with a spacer 34, the spacer 34 is connected to the body gear 2 through a set screw 35, the shaft hub 4 is located inside the body gear 2, and the side of the shaft hub 4 close to the chassis 1 goes outward in turn The first friction assembly, the second friction assembly and the third friction assembly are sleeved, and the first fri...

Embodiment 2

[0036] like figure 1 , figure 2 and Figure 4 As shown, the split clutch brake of the present invention includes a brake 48 and a clutch 47. The brake 48 is connected to the bed through a positioning ring, the clutch 47 is connected to the flywheel, and the clutch 47 is connected to the brake 48 through the transmission shaft and the air circuit control system. The brake 48 and clutch 47 all include chassis 1, body gear 2, shaft hub 4, first friction assembly, second friction assembly, third friction assembly, cylinder assembly and air intake disc 37, chassis 1 is connected to the body by chassis screws and spring washers 3 Gear 2, the body gear 2 is provided with a spacer 34, the spacer 34 is connected to the body gear 2 through a set screw 35, the shaft hub 4 is located inside the body gear 2, and the side of the shaft hub 4 close to the chassis 1 goes outward in turn The first friction assembly, the second friction assembly and the third friction assembly are sleeved, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com