A paper feeding method with self-adaptive starting point

A starting point, self-adaptive technology, applied in the direction of thin material processing, transportation and packaging, object supply, etc., can solve the problems of affecting service life, affecting machine stability, paper feeding accuracy, increasing the acceleration of cam servo motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

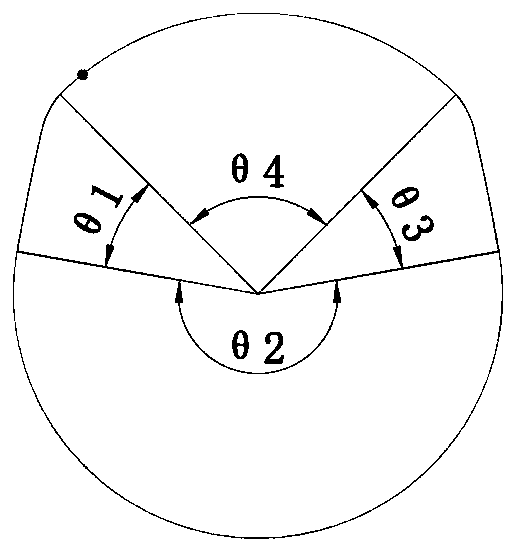

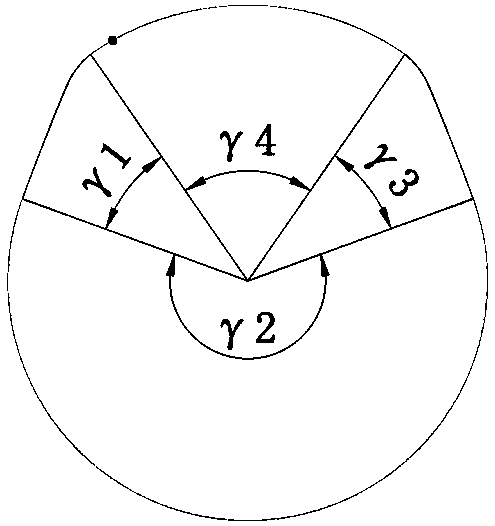

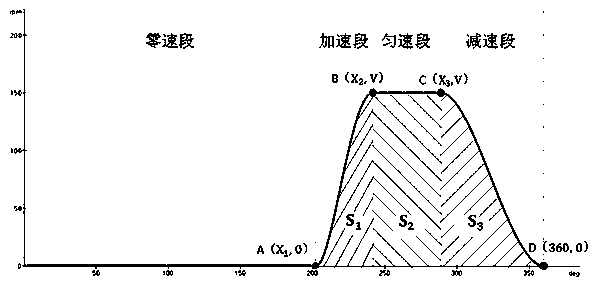

[0061] A method for feeding paper according to the length of the cardboard self-adapting to the starting point of the paper feeding wheel relative to the main shaft, which includes the following steps: S1. Designing a mechanical cam C 1 、C 2 :C 1 It is used to control the up and down movement of the front end of the lifting platform, such as figure 1 Shown; C 2 It is used to control the up and down movement of the end of the lifting platform, such as figure 2 Shown; Cam C 1 , C 2 The angles are defined as follows:

[0062] cam C 1 Angle definition: ,

[0063] cam C 2 Angle definition: ;

[0064] In the middle of actual design, the key points of cam angle design of the present invention are:

[0065] 1. θ 1 , gamma 1 , θ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com