A processing technology of durable measuring tape based on stainless steel substrate

A processing technology, stainless steel technology, applied in the processing technology field of durable measuring tape, can solve problems such as easy to be worn off, easy to change color of the tape, short life of the tape, etc., to achieve long service life, uniform deformation thickness, curvature stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

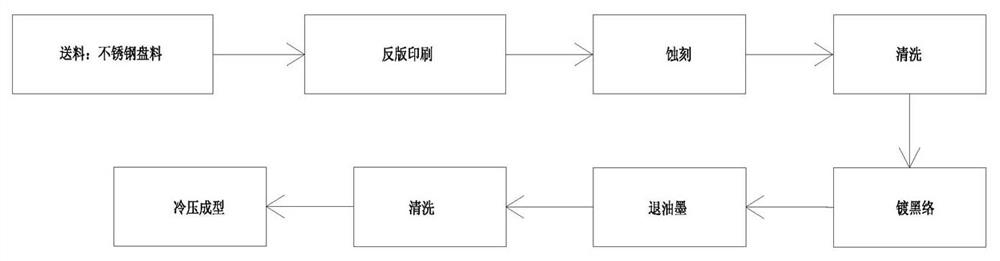

[0021] Such as figure 1 Shown, a kind of processing technology of durable measuring tape based on stainless steel substrate, comprises the following steps:

[0022] Step 1), feeding, select a stainless steel coil with a thickness of 0.15mm and a hardness of HV530-HV550;

[0023] Step 2), reverse printing, the plated stainless steel substrate passes through the reverse printing machine, and the UV-resistant ink is printed on both sides of the stainless steel substrate under the action of the ink spreader, where the Mig line and the number of the stainless steel substrate are For non-printing, the feeding speed of the stainless steel substrate is consistent with the printing speed of the ink distribution wheel;

[0024] Step 3) The printed stainless steel substrate is sent to the stainless steel etching line in the form of a plate for chemical etching. The unprinted Mige lines and numbers on the stainless steel substrate are etched with grooves. After the etching is completed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com