Sand bottom technique and mold thereof

A process and mold technology, applied in the field of production process and mold, sand bottom process and mold field, can solve the problems of pilling, high price, waste, etc., and achieves the goal of not easy to break, low cost, and simple and easy processing. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

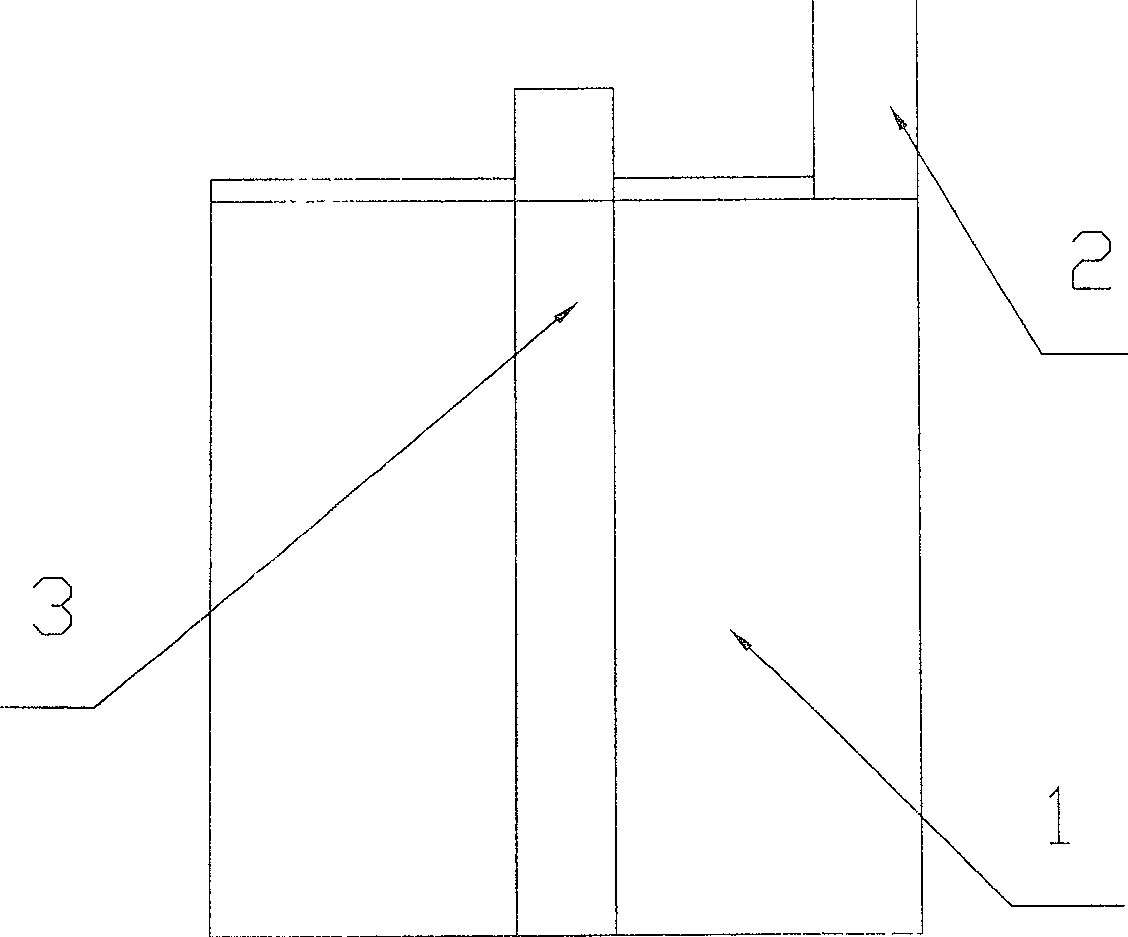

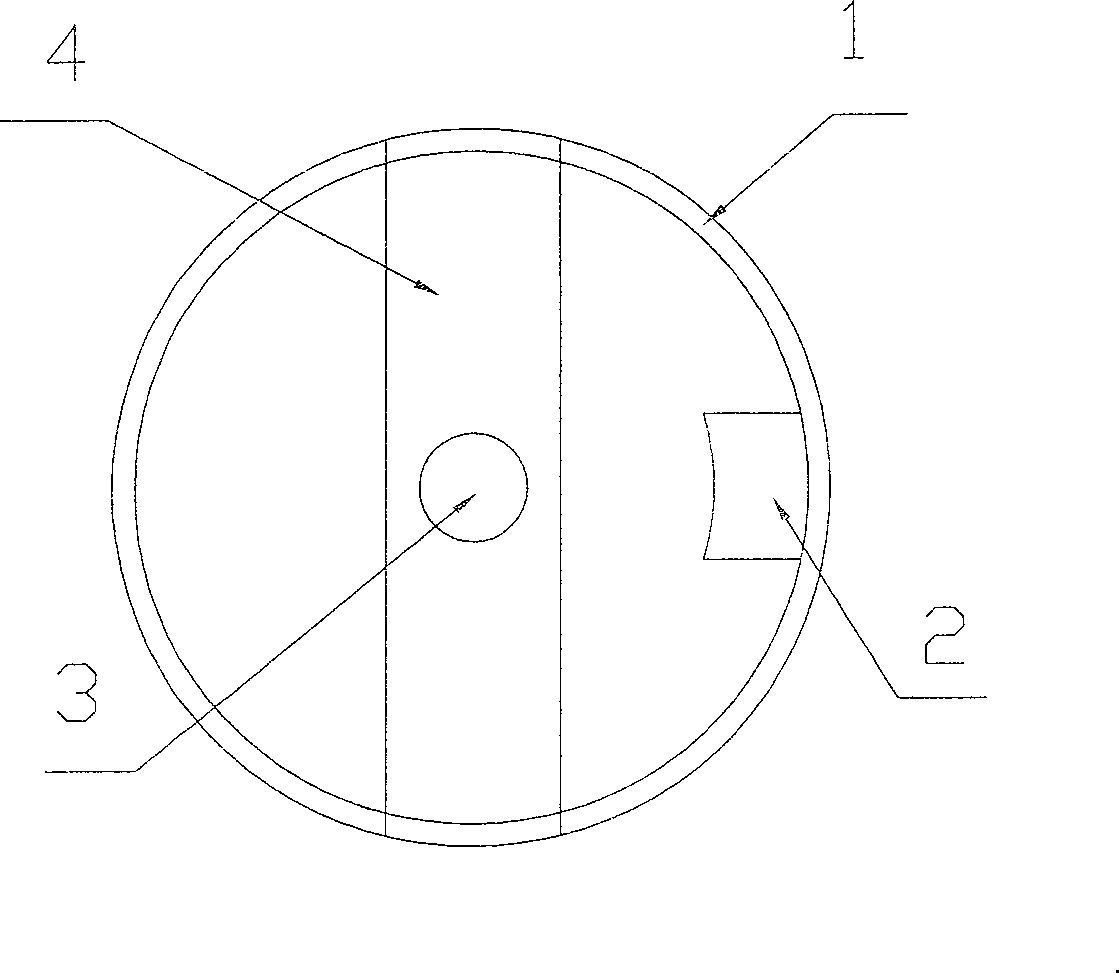

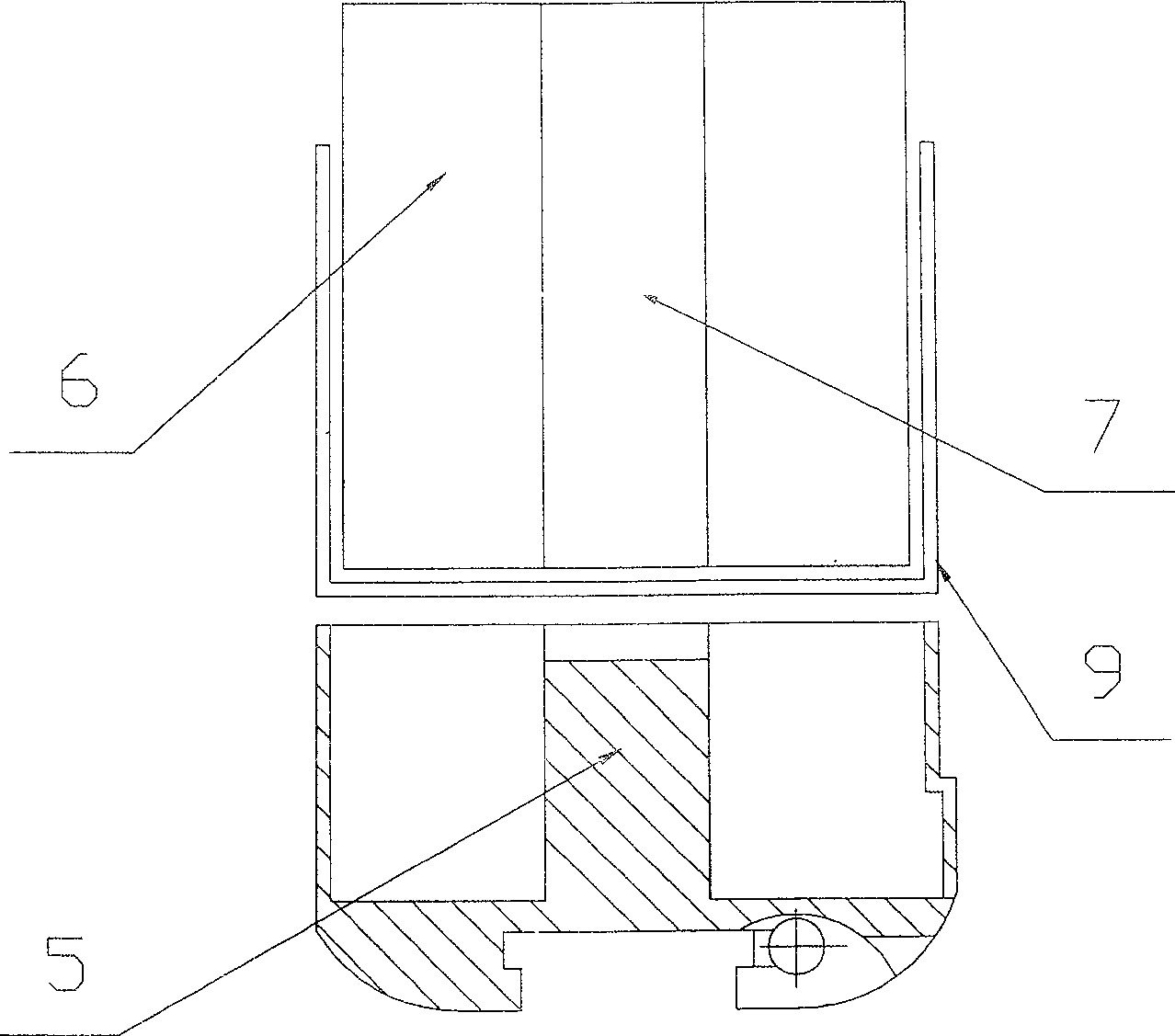

[0028] Example 1, such as figure 1 , figure 2 As shown, there is a circular cylinder 3 coaxial with it in the middle of the annular fixed support 1, the circular cylinder 3 is a hollow annular cylinder, and there are fixed bars 4 at the bottom of the fixed support 1, and the fixed bars 4 The two ends are in contact with the fixed support 1, the circular cylinder 3 is installed on the fixed bar 4, there is a semi-circular fixed bar 2 on the side wall of the fixed support 1, and the semi-circular fixed bar 2 and the annular fixed support 1 The axes are parallel; if image 3 Shown, turning head 6 is made of rubber, and its diameter is identical or approximate with the diameter of sewing machine bobbin case, and the center of turning head 6 has a through hole 7, and the diameter of through hole 7 is identical with rotating shaft 5 or approximates.

[0029] When used, such as image 3 , Figure 4 As shown, when the mold is working, it is mixed with sandpaper, contacts with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com