Production process of weft-knitted wool-like fabric

A production process and velvet-like technology, which is applied in the production process of weft-knitted velvet-like fabrics, can solve the problems of unsuitable control of fabric color fastness, unguaranteed quality, long production and processing process, etc. The effect of control, quality assurance, and short production and processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

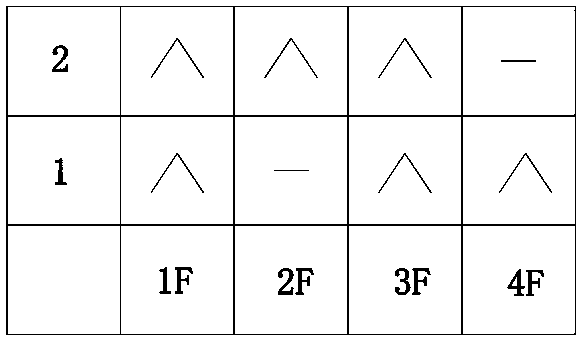

[0032] like figure 1 Shown, it is a kind of production technology of weft-knitted fleece-like fabric, comprises the following steps:

[0033] (1) Fabric selection: 40D polyester DTY, 20D superfine polyester fiber DTY and 20D spandex are selected; the 40D polyester DTY is used as the veil, 20D superfine polyester fiber DTY is used as the bottom yarn and 20D spandex is used as the lining yarn;

[0034] (2) Model selection: use a 28-needle, 34-inch, 104-way large open-width circular machine for weaving; use this large circular machine to ensure the tightness of the coil structure and the fineness of the fabric surface;

[0035] (3) Weaving process:

[0036] Needle arrangement method: two needles for one cycle, two needles include the first needle 1 and the second needle 2;

[0037] Triangular arrangement method: triangular arrangement of four roads and one cycle, four roads include the first road 1F, the second road 2F, the third road 3F and the fourth road 4F; among them, the...

Embodiment 2

[0045] like figure 1 Shown, it is a kind of production technology of weft-knitted fleece-like fabric, comprises the following steps:

[0046] (1) Fabric selection: 70D polyester DTY, 30D superfine polyester fiber DTY and 45D spandex are selected; the 70D polyester DTY is used as the veil, the 30D superfine polyester fiber DTY is used as the bottom yarn and the 45D spandex is used as the lining yarn;

[0047] (2) Model selection: use a 32-needle, 34-inch, 104-way large open-width circular machine for weaving; use this large circular machine to ensure the tightness of the coil structure and the fineness of the fabric surface;

[0048] (3) Weaving process:

[0049] Needle arrangement method: two needles for one cycle, two needles include the first needle 1 and the second needle 2;

[0050] Triangular arrangement method: triangular arrangement of four roads and one cycle, four roads include the first road 1F, the second road 2F, the third road 3F and the fourth road 4F; among t...

Embodiment 3

[0058] like figure 1 Shown, it is a kind of production technology of weft-knitted fleece-like fabric, comprises the following steps:

[0059](1) Fabric selection: 100D polyester DTY, 40D superfine polyester fiber DTY and 70D spandex are selected; the 100D polyester DTY is used as the veil, 40D superfine polyester fiber DTY is used as the bottom yarn and 70D spandex is used as the lining yarn;

[0060] (2) Model selection: use a 36-needle, 34-inch, 104-way open-width large circular machine for weaving, and use this large circular machine to ensure the tightness of the coil structure and the fineness of the fabric surface;

[0061] (3) Weaving process:

[0062] Needle arrangement method: two needles for one cycle, two needles include the first needle 1 and the second needle 2;

[0063] Triangular arrangement method: triangular arrangement of four roads and one cycle, four roads include the first road 1F, the second road 2F, the third road 3F and the fourth road 4F; among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com