Self-refilling oil chain disc

A technology of chain disc and engine oil, which is applied in the field of sprockets, can solve the problems of low work efficiency and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

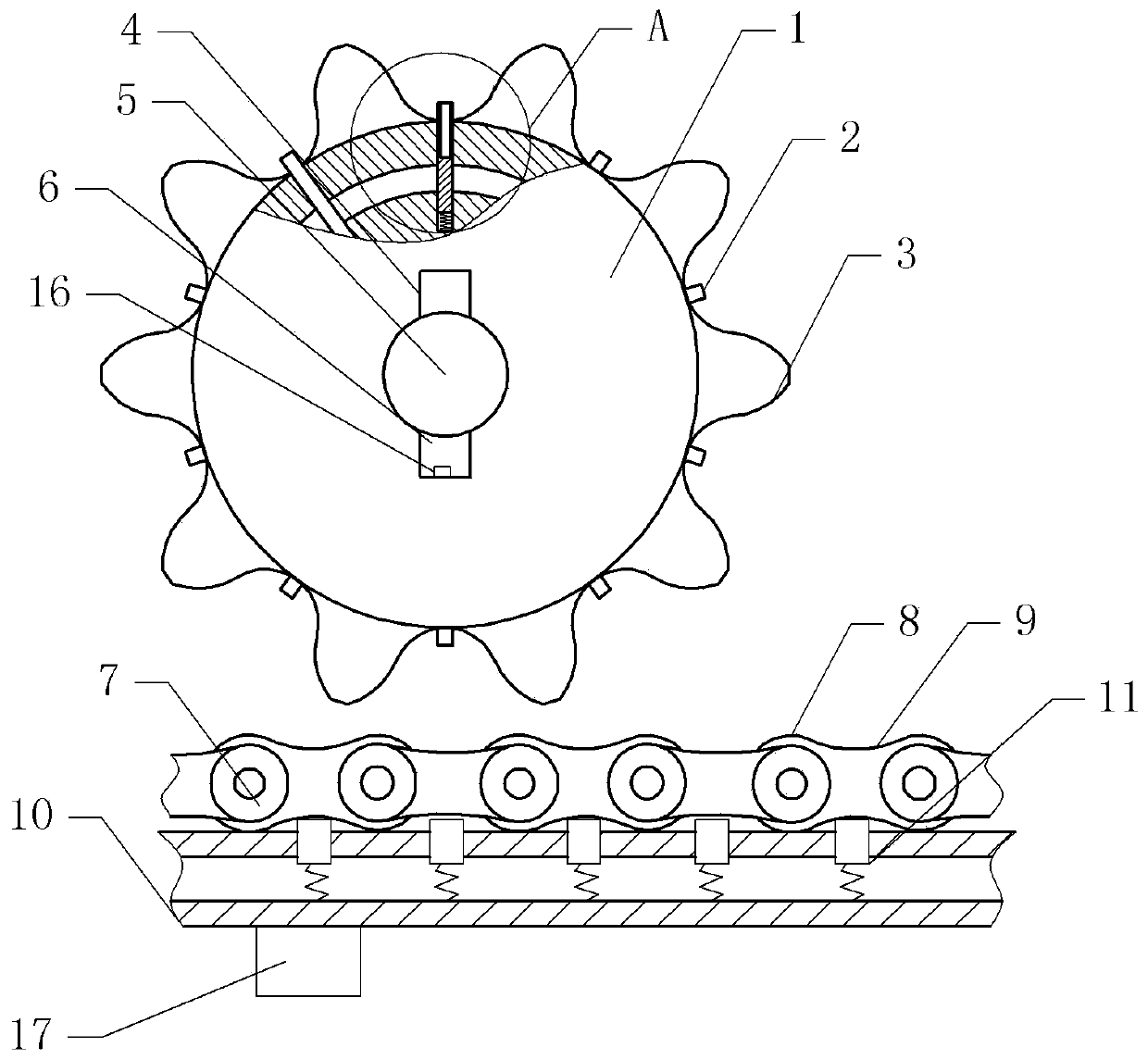

[0023] as attached figure 1 As shown, a self-replenishing engine oil chain disc includes a sprocket body 1 and a casing 10 sheathed on the outer periphery of the sprocket body 1, and a space for placing a chain 7 is provided between the sprocket body 1 and the casing 10, such that the sprocket The positional relationship of the body 1, the chain 7 and the housing 10 is from inside to outside. The chain 7 includes a plurality of identical chain links, and two adjacent chain links are linked to each other, so the chain 7 includes an engaging portion 9 meshing with the protruding tooth 3 and also includes a protrusion 8 .

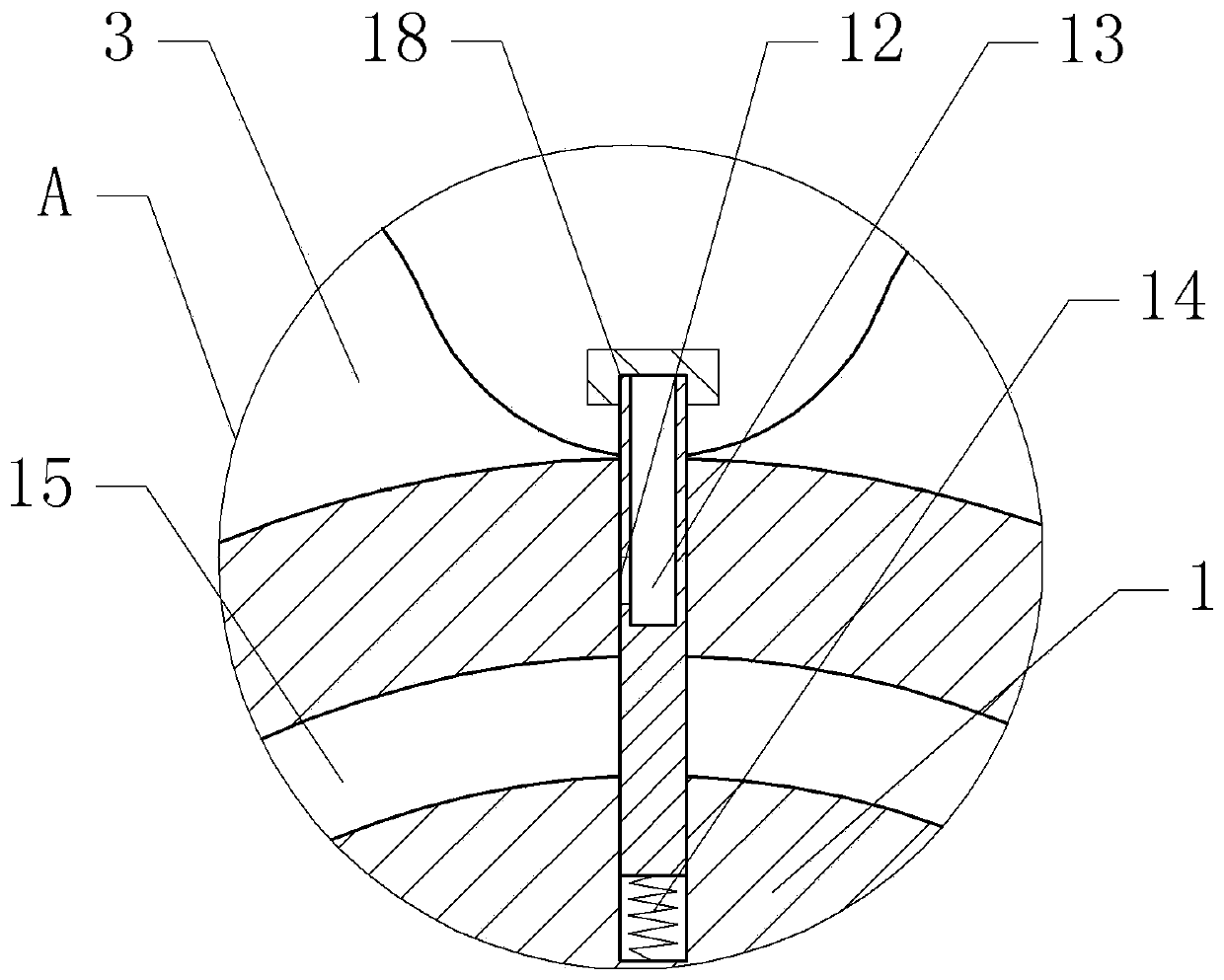

[0024] The sprocket body 1 is provided with a fixing hole 5, the shape of the fixing hole 5 can be changed according to different drive shafts, and the fixing hole 5 can be circular, square, rectangular or the like. The outer periphery of the fixing hole 5 is provided with a first supply groove 6 and a second supply groove 4 , and an oil passage 15 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com