A tractor static rollover stability test bench

A technology of stability test and tractor, which is applied in the testing of machine/structural components, vehicle testing, instruments, etc. It can solve the problems of complex operation, heavy workload, and low testing efficiency, and achieve low control cost and high measurement and control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

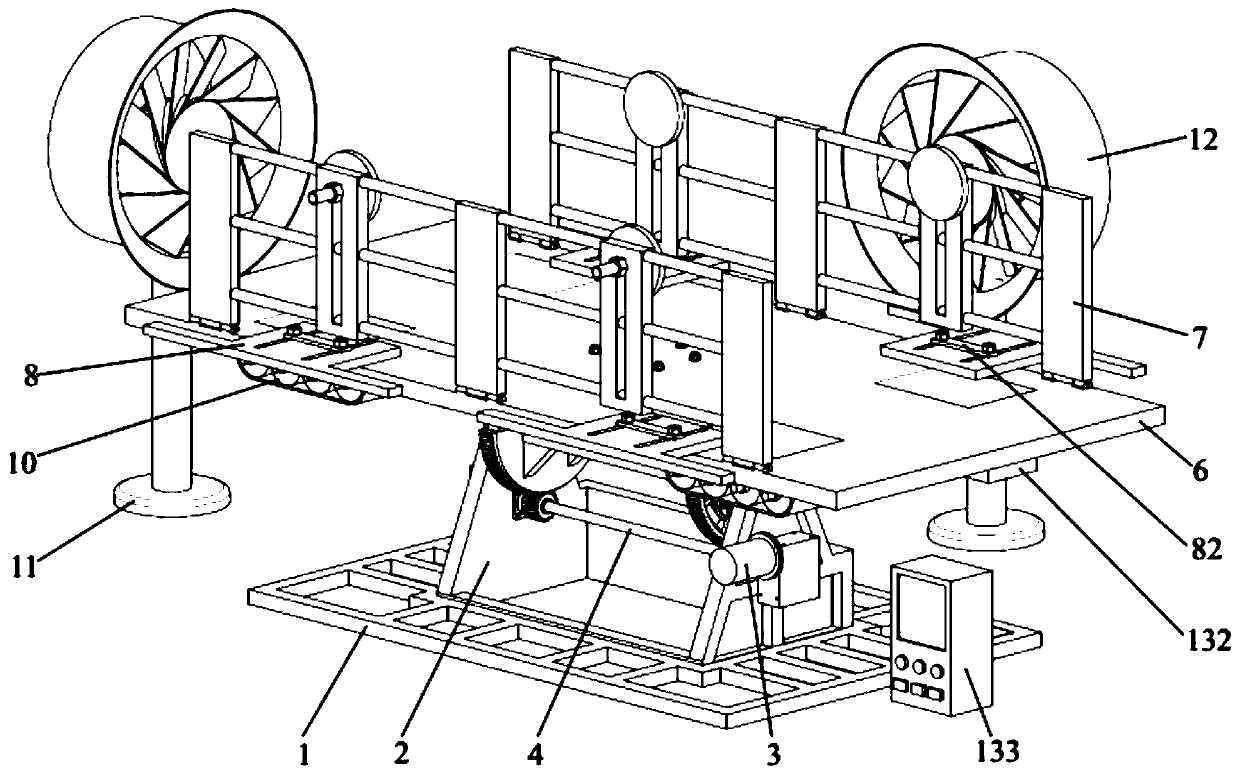

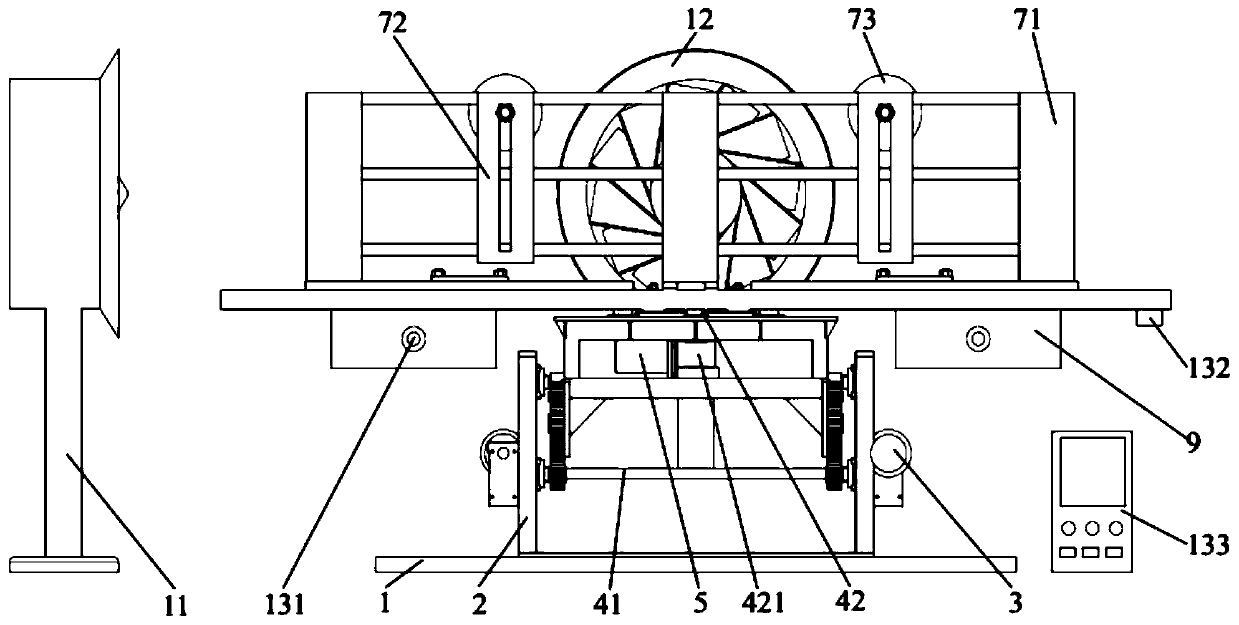

[0043] Such as Figure 1-6 As shown, a tractor static rollover stability test bench includes a base 1, a test bench 6, a power unit and a transmission device 4, the base 1 is provided with a frame 2, and the transmission device 4 is installed on the On the frame 2, the transmission device 4 is respectively connected with the power device and the test bench 6; the transmission device 4 includes a rollover transmission mechanism 41 and a horizontal rotation mechanism 42, and the rollover transmission mechanism 41 is installed On the frame 2, the horizontal rotation mechanism 42 is installed on the rollover transmission mechanism 41; the rollover transmission mechanism 41 includes a first transmission 411, a drive gear shaft 412, a drive gear bearing seat 413, a Gear 414, driven gear 415, turntable 416 and turntable bearing block 417, described first speed changer 411 is connected with described power unit and described driving gear shaft 412 respectively, and described driving g...

Embodiment 2

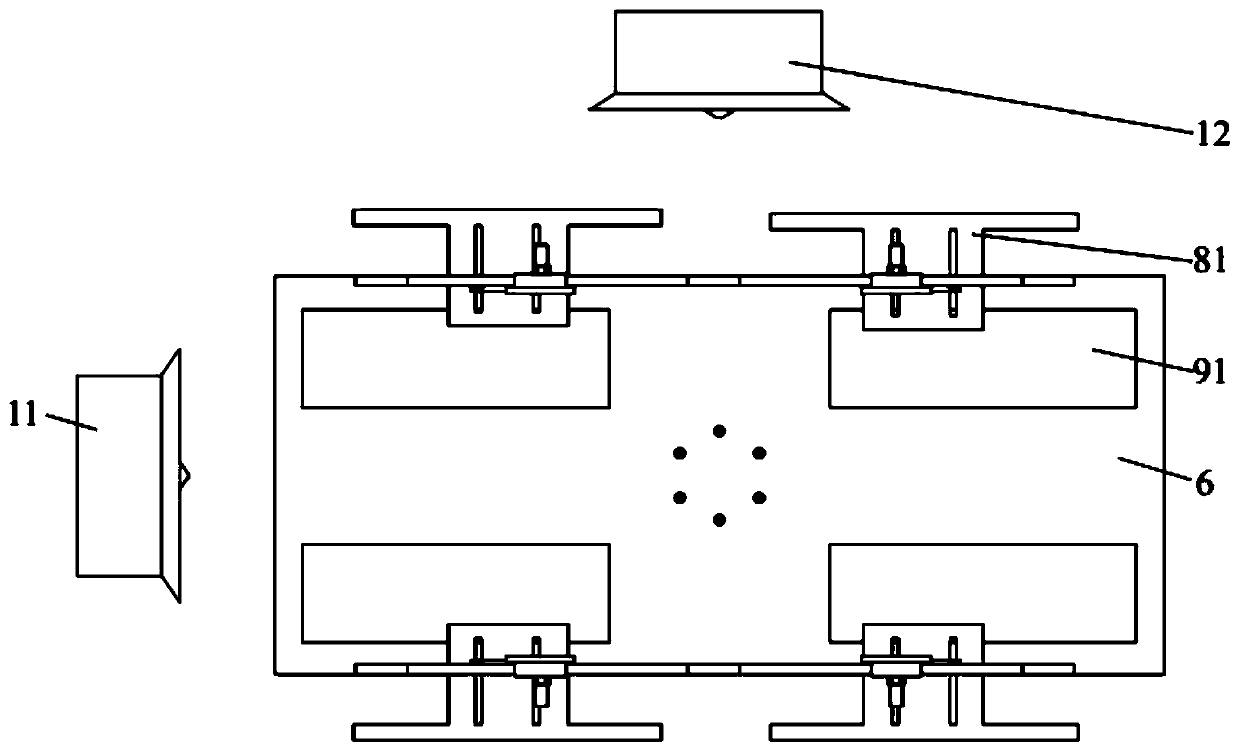

[0046] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present embodiment also includes a safety protection device 7, an anti-skid device 8 and a measurement and control system, and the safety protection device 7 and the anti-side Sliding devices 8 are all installed on both sides of the test bench 6 along the direction of tractor travel, and a side wind fan 12 is arranged on one side of the safety protection device 7, and the front of the test bench 6 along the direction of tractor travel is also A forward air resistance fan 11 is provided; the signal output terminals of the measurement and control system are respectively connected to the signal input terminals of the wheel alignment device and the signal input terminals of the test bench 6 .

[0047] In consideration of safety, a safety protection device 7 and an anti-skid device 8 are installed to prevent the tractor from falling during the test and ensure safe and reliable operation. At the same time, the tr...

Embodiment 3

[0049] Such as Figure 1-7 As shown, in this embodiment, on the basis of Embodiment 1, the safety protection device 7 includes a guardrail 71, a protective frame 72 and an anti-rollover baffle 73, and the guardrail 71 is installed on the test bench 6, so The protective frame 72 is movably installed on the guardrail 71 , and the anti-rollover baffle 73 is movably installed on the protective frame 72 .

[0050] Setting the safety protection device 7 is to ensure that the tractor prevents the tractor from rolling over at the maximum static rollover stability angle, and in order to adapt to the rollover protection of tractors of different specifications during the test process, the protective frame 72 is movable on the guardrail 71, preventing sideways The flapper 73 is movably connected with the protective frame 72 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com