Method for carrying out in-situ measurement on precipitation amount of Fe3C in low-carbon alloy steel

A low-carbon alloy steel, in-situ measurement technology, used in measurement devices, analytical materials, material thermal analysis and other directions, can solve problems such as strength reduction, and achieve the effects of strong applicability, wide application prospects, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: concrete steps are as follows:

[0031] (1) The low-carbon alloy steel sample to be tested is processed into a cuboid with a specification of 80×10×5mm, which is subjected to a high-temperature solution treatment at 910°C, kept for 120 minutes and then quenched in water, and the steel sample after the high-temperature solution treatment is processed into a 2-3 internal friction test samples with a specification of 1.5×2.5×65mm, the surface is polished with 100#—200#—400#—600#—800# sandpaper in sequence, and then polished to make the surface smooth.

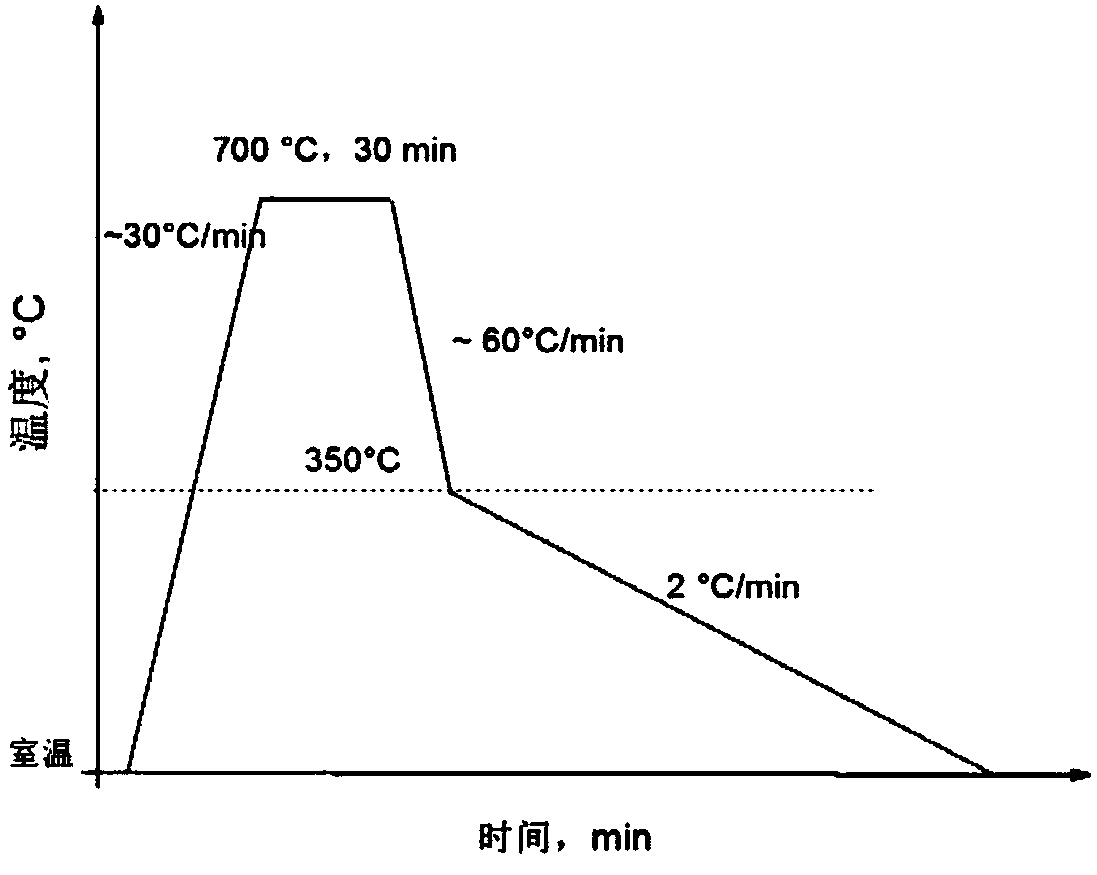

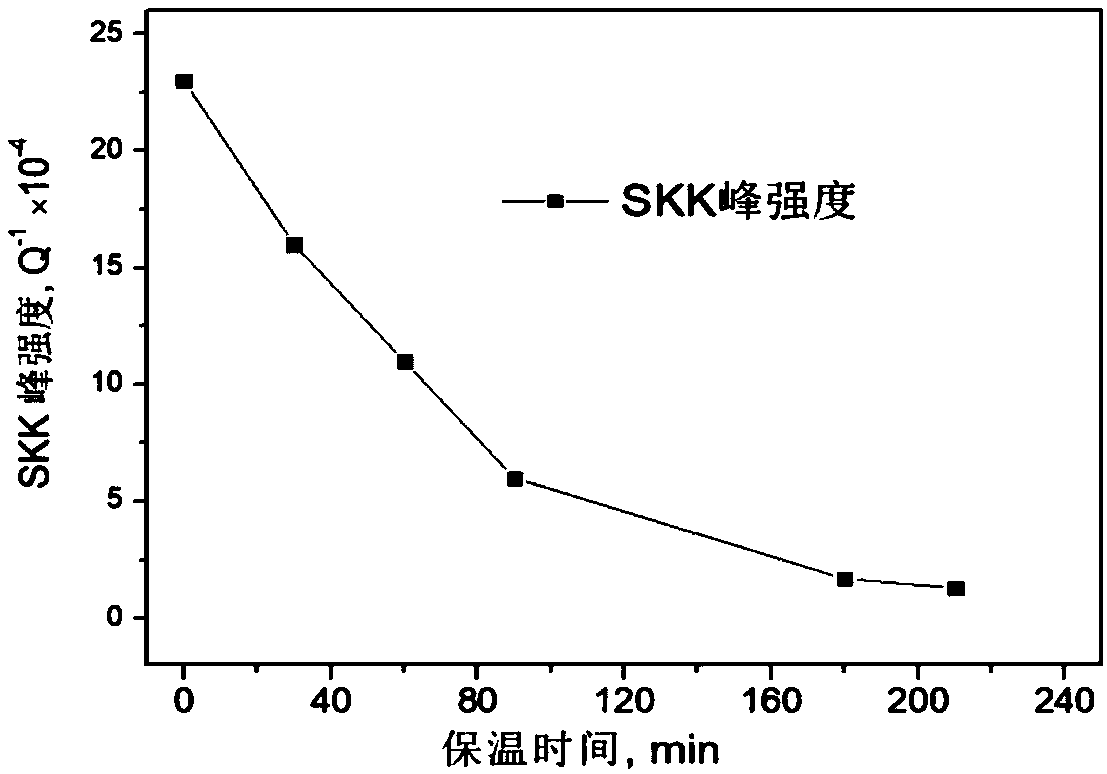

[0032] (2) Install one of the above-mentioned internal friction test samples on the MFP-1000 internal friction tester. After pumping a high vacuum, the temperature is rapidly raised from room temperature to 350°C at a heating rate of 30°C / min. After reaching 350°C, the temperature is lowered immediately, and the temperature is lowered during the test. For the SKK peak in the process, the cooling rate is 2°C / mi...

Embodiment 2

[0037] Embodiment 2: concrete steps are as follows:

[0038] (1) The low-carbon alloy steel sample to be tested is processed into a cuboid with a specification of 80×10×5mm, which is subjected to a high-temperature solution treatment at 910°C, kept for 120 minutes and then water-quenched. All the C atoms in the steel sample are solid-solved Exists in the form of Fe-free 3 C precipitation; the steel sample after high temperature solution treatment is processed into 2-3 internal friction test samples with a specification of 1.5×2.5×65mm, and the surface is polished with 100#—200#—400#—600#—800# sandpaper , and then polished to make the surface smooth.

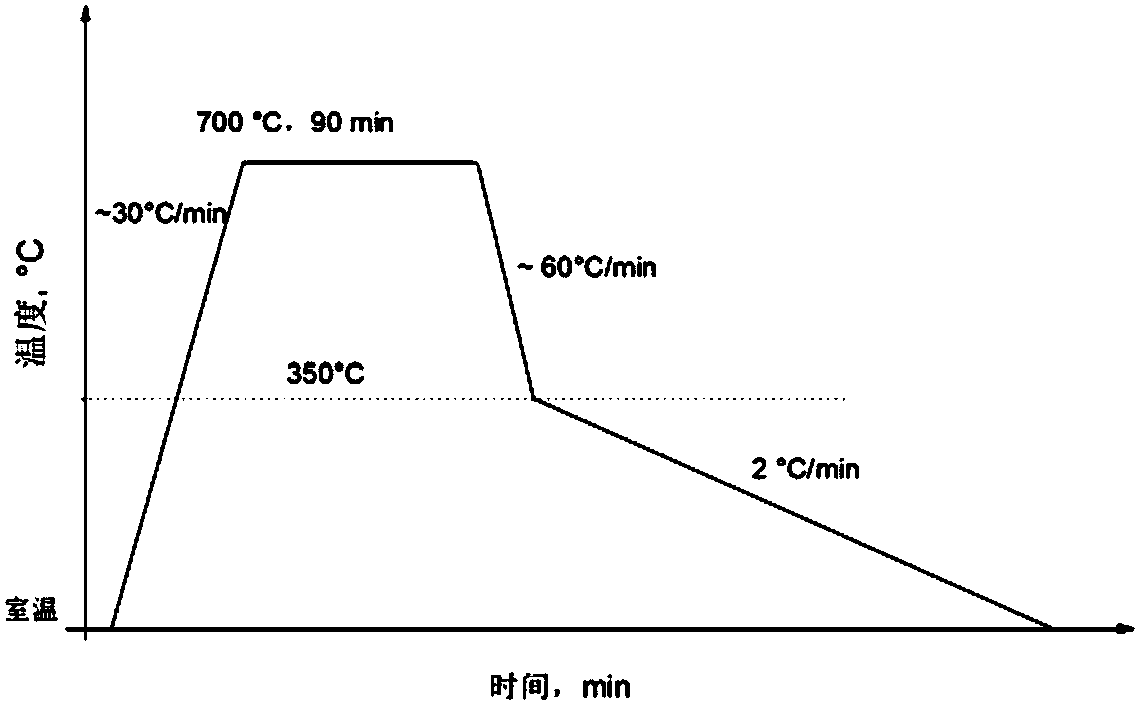

[0039] (2) Install one of the above-mentioned internal friction test samples on the MFP-1000 internal friction instrument. After pumping a high vacuum, the temperature is rapidly raised from room temperature to 350°C, and the heating rate is 30°C / min. After reaching 350°C, the temperature is immediately lowered, and the temperat...

Embodiment 3

[0043] Embodiment 3: concrete steps are as follows:

[0044] (1) The low-carbon alloy steel sample to be tested is processed into a cuboid with a specification of 80×10×5mm, subjected to high-temperature solution treatment at 930°C, and water quenched after 120 minutes of heat preservation. The C atoms in the steel sample are all in solid solution Exists in the form of Fe-free 3 C precipitation, the steel sample after high temperature solid solution treatment is processed into 2-3 internal friction test samples with a specification of 1.5×2.5×65mm, and the surface is polished with 100#—200#—400#—600#—800# sandpaper , and then polished to make the surface smooth.

[0045] (2) Install one of the above-mentioned internal friction test samples on the MFP-1000 internal friction instrument. After pumping a high vacuum, the temperature is rapidly raised from room temperature to 350°C, and the heating rate is 30°C / min. After reaching 350°C, the temperature is immediately lowered, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com