Automatic lifting and feeding method for battery pole piece die cutting

A battery pole piece and feeding technology, applied in battery electrodes, electrode manufacturing, battery assembly machines, etc., can solve the problem of not having very mature equipment popularized in the market, and achieve the advantages of large-scale production, strong reliability, and solving the problem of jamming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

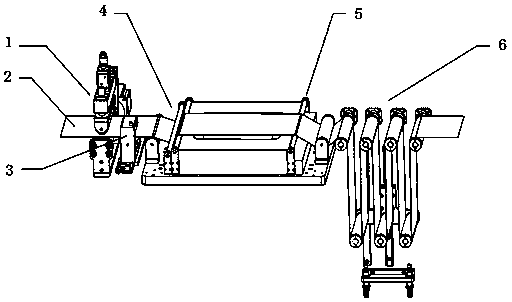

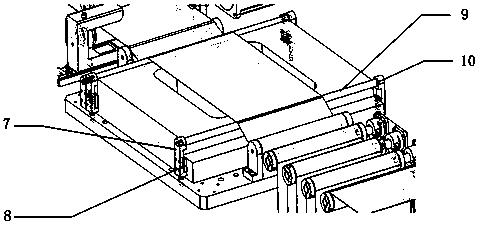

[0016] Such as figure 1 Or shown in 2 is a battery pole piece die-cutting automatic lifting and feeding method of the present invention, including PLC, photoelectric sensor, linear guide rail, bearing, rotating shaft, spring, floating limit plate, motor, cylinder, rubber coating roller, constant Compression cylinder, fixed plate, etc. The motor, cylinder, rubber roller, linear bearing, guide rod, bearing, photoelectric sensor, and fixed plate are combined to form a feeding module; the bearing, rotating shaft, and spring are assembled on a floating limit plate, and fixed on the mold through a linear guide rail. Or on the fixed plate, so that it can be combined into a floating module that can float up and down after being subjected to vertical pressure and has a limit function; line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com