Lathe fixture device

A lathe jig and jig technology, which is applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of single workstation, time-consuming, inability to improve processing efficiency, etc., and achieve the effect of jig optimization and work efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

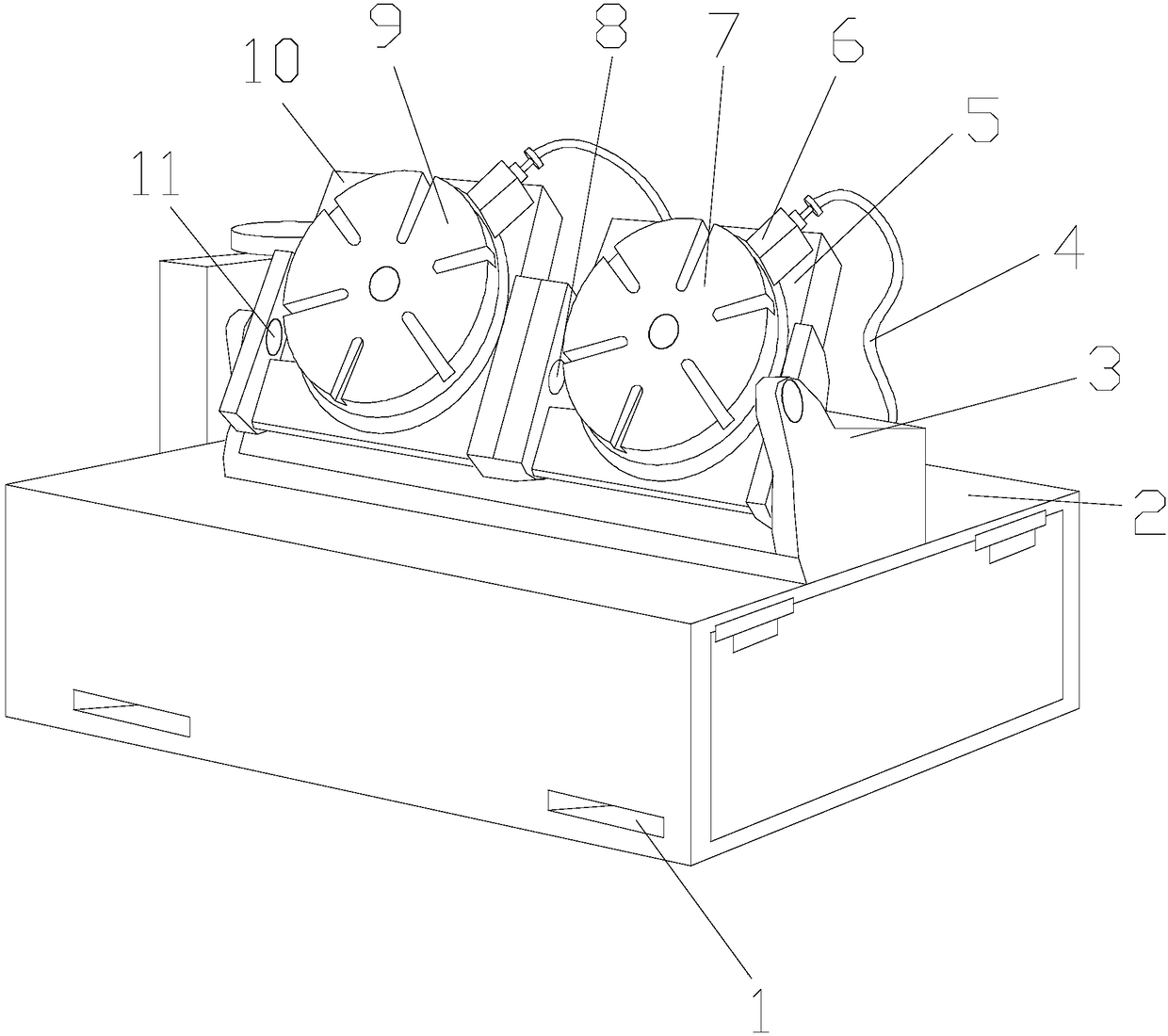

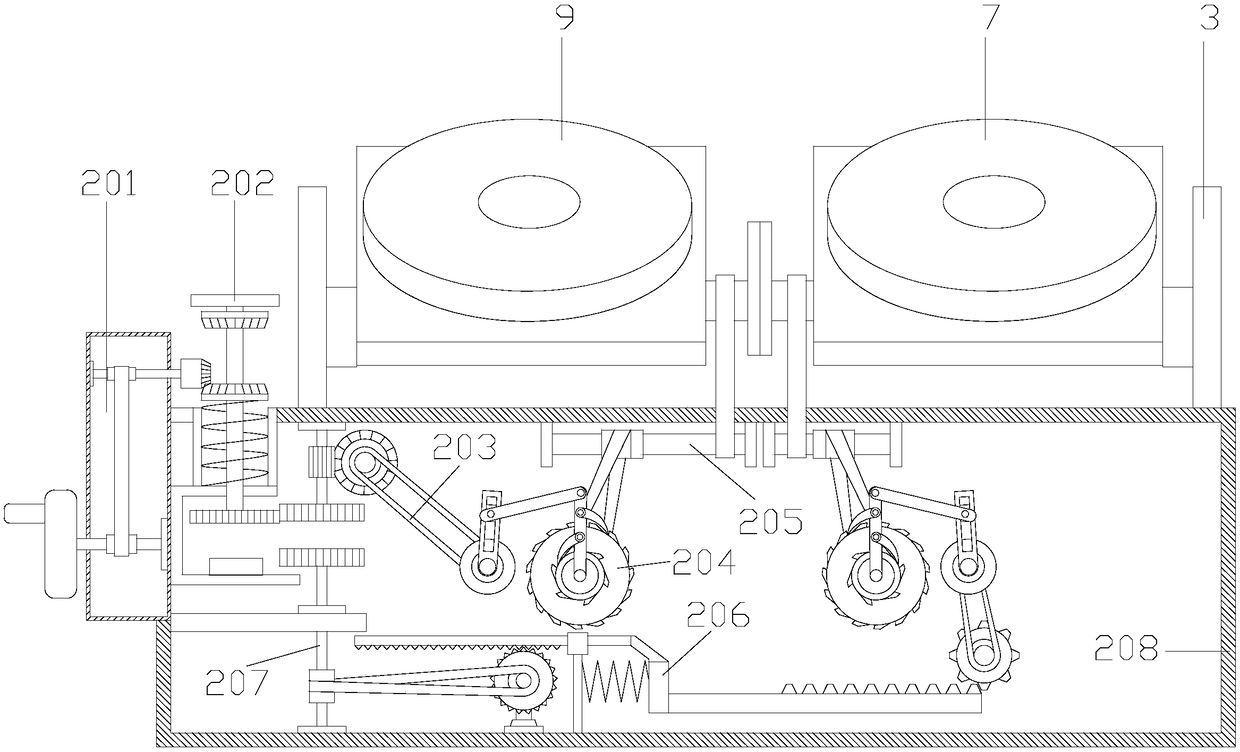

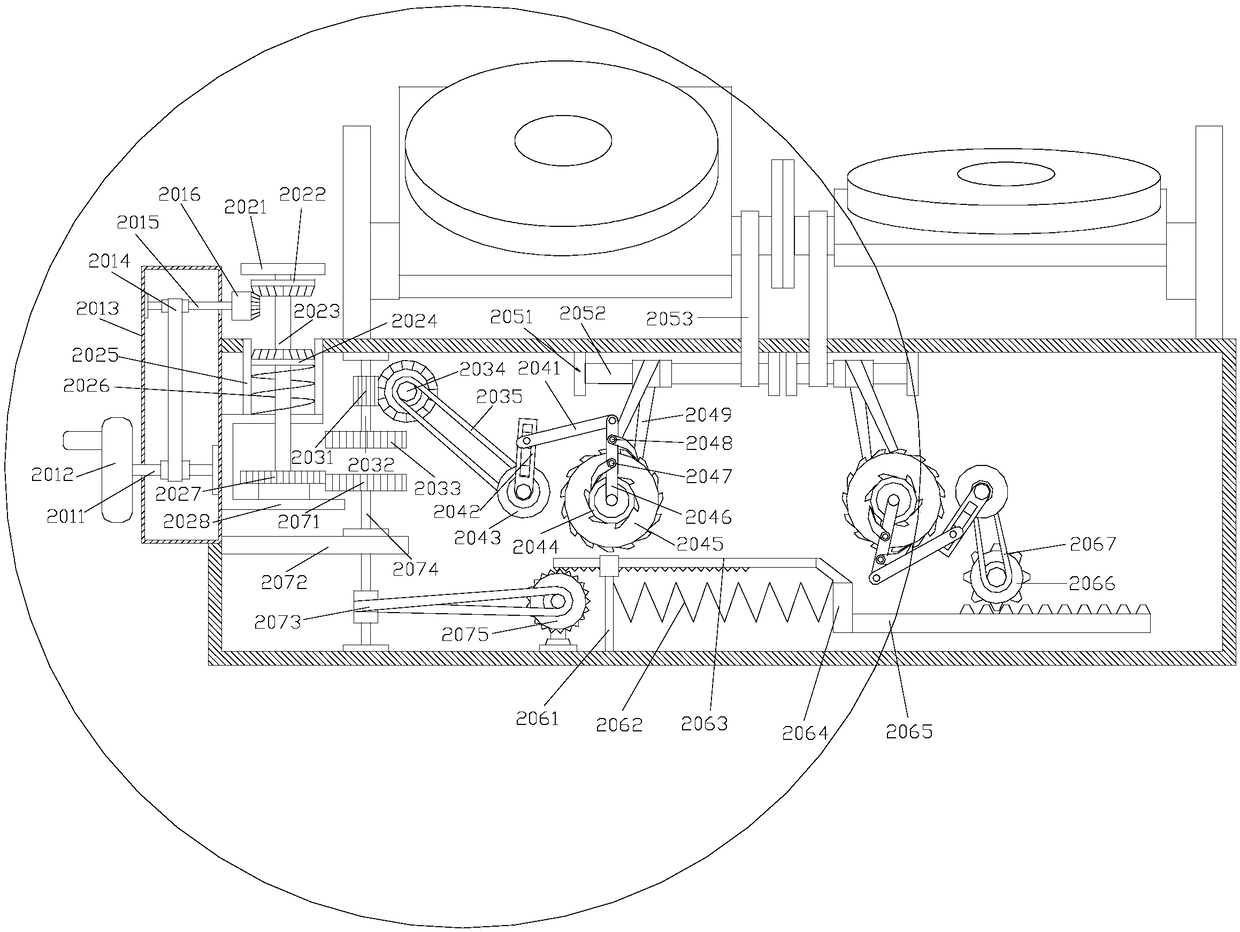

[0024] see Figure 1-Figure 4 , the present invention provides a lathe clamp device: its structure includes a positioning hole 1, a clamp base 2, a fixed frame 3, a vacuum tube 4, a first turning plate 5, a vacuum joint 6, a first clamp 7, a first turning shaft 8, a second Two fixtures 9, a second turning plate 10, and a second turning shaft 11, the positioning holes 1 are provided with more than two and are evenly and equidistantly distributed on the side of the fixture base 2, and the bottom of the fixed frame 3 is installed by buckling In the middle part of the upper end of the clamp base 2, the first turning plate 5 and the second turning plate 10 are fastened and mounted on the middle part of the fixed frame 3 through the first turning shaft 8 and the second turning shaft 11 respectively, and the first fixture 7 1. The bottom of the second clamp 9 is connected to the first flipping plate 5 and the second flipping plate 10 respectively by means of embedding, and the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com