Array type elastic negative pressure fetching sucker

An array type suction cup technology, which is applied in the development field of industrial automation material suction devices, can solve the problems of unsuitable metal sheets, inconsistent heights, and the inability to perform batch array suction with a single suction cup, so as to achieve high suction operation efficiency and strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail now in conjunction with accompanying drawing.

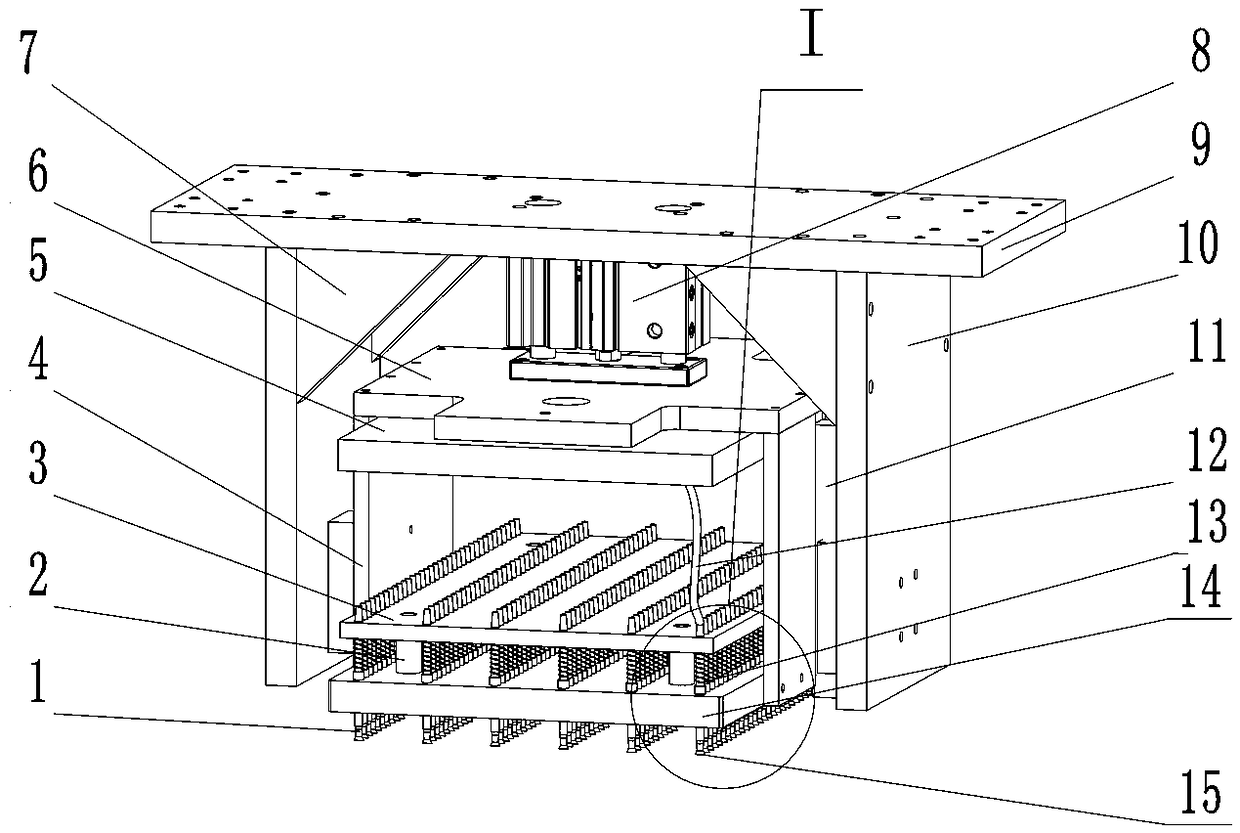

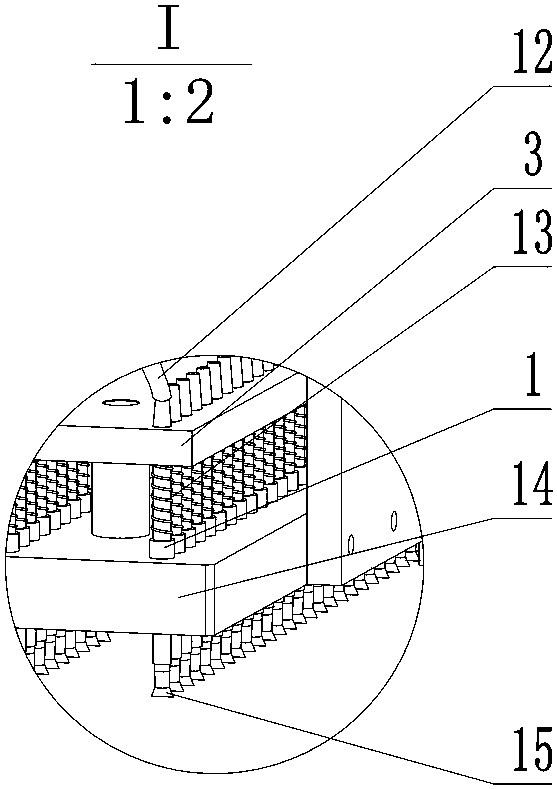

[0020] Such as Figure 1 to Figure 2 The array type elastic negative pressure retrieving suction cup shown can be divided into three parts in terms of structure and function, including a pneumatic drive assembly, a guide assembly, and a flexible suction cup assembly.

[0021] The pneumatic drive assembly includes a telescopic reinforcement plate 7, a straight cylinder 8, a base plate 9, and a side telescopic plate 10. The guide assembly includes a suction pipe group side plate 4, a cylinder connecting plate 6, and a linear guide rail 11. The flexible suction cup assembly includes a copper suction pipe 1 and a round support rod. 2. Spring baffle 3, suction cup 5, air pipe 12, spring 13, guide plate 14, rubber suction nozzle 15.

[0022] The side telescopic plate 10 is fixedly connected with the base plate 9 in the vertical direction, and the connection strength is streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com