Underground pipe gallery curing shaping device

An underground pipe gallery and pipe gallery technology, which is applied to underwater structures, water conservancy projects, artificial islands, etc., can solve the problems of increasing the working pressure of operators, the easy deformation of the pipe gallery space, and the uneven inner wall of the pipe gallery. The corridor is professionally shaped, the inner diameter of the pipe gallery is ensured, and the construction period is shortened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

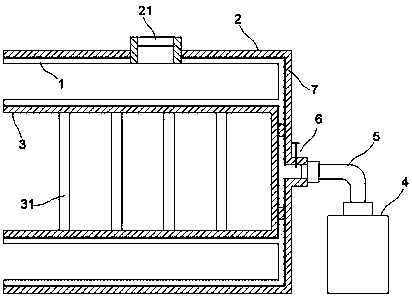

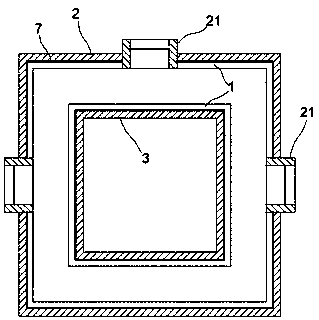

[0013] exist figure 1 , figure 2 In the shown embodiment, the solidification and shaping device of the local lower pipe gallery includes a shaping frame and an adjustment layer 1; the shaping frame includes an outer plastic frame 2 and an inner plastic frame 3, and the outer plastic frame 2 and the inner plastic frame 3 are fixedly connected; a support rod 31 is provided between the opposite frame walls of the inner plastic frame 3, and a grouting hole 21 is provided on the outer plastic frame 2; the adjustment layer 1 covers the outer wall of the inner plastic frame 3 and the outer plastic The inner wall of the frame 2, the adjustment layer 1 includes an air bag made of a flexible material, and the air bag is filled with an adjustment liquid, and the adjustment liquid is an electrorheological fluid; The cavity 4 is connected, and a regulating valve 6 is arranged between the regulating layer 1 and the guide tube 5; a conductive wire mesh 7 is laid in the regulating layer 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com