Damper with overload protection and electric tail gate support rod

A technology of overload protection and damper, which is applied in the field of electric tailgate struts, and can solve problems such as lack of overload protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The invention discloses a damper for overload protection and an electric tailgate strut, which can effectively solve the technical defect that the existing electric tailgate strut does not have the function of overload protection.

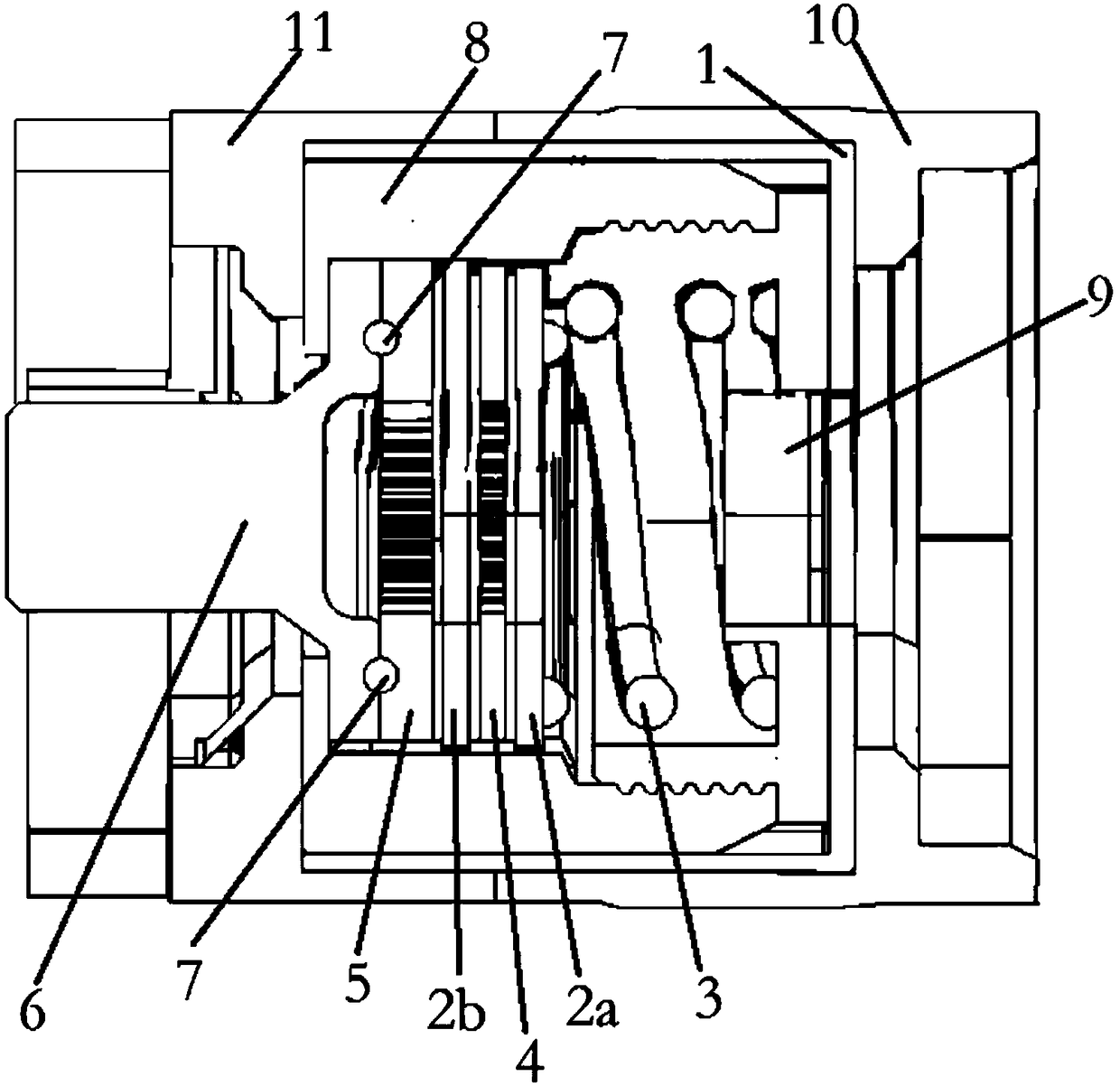

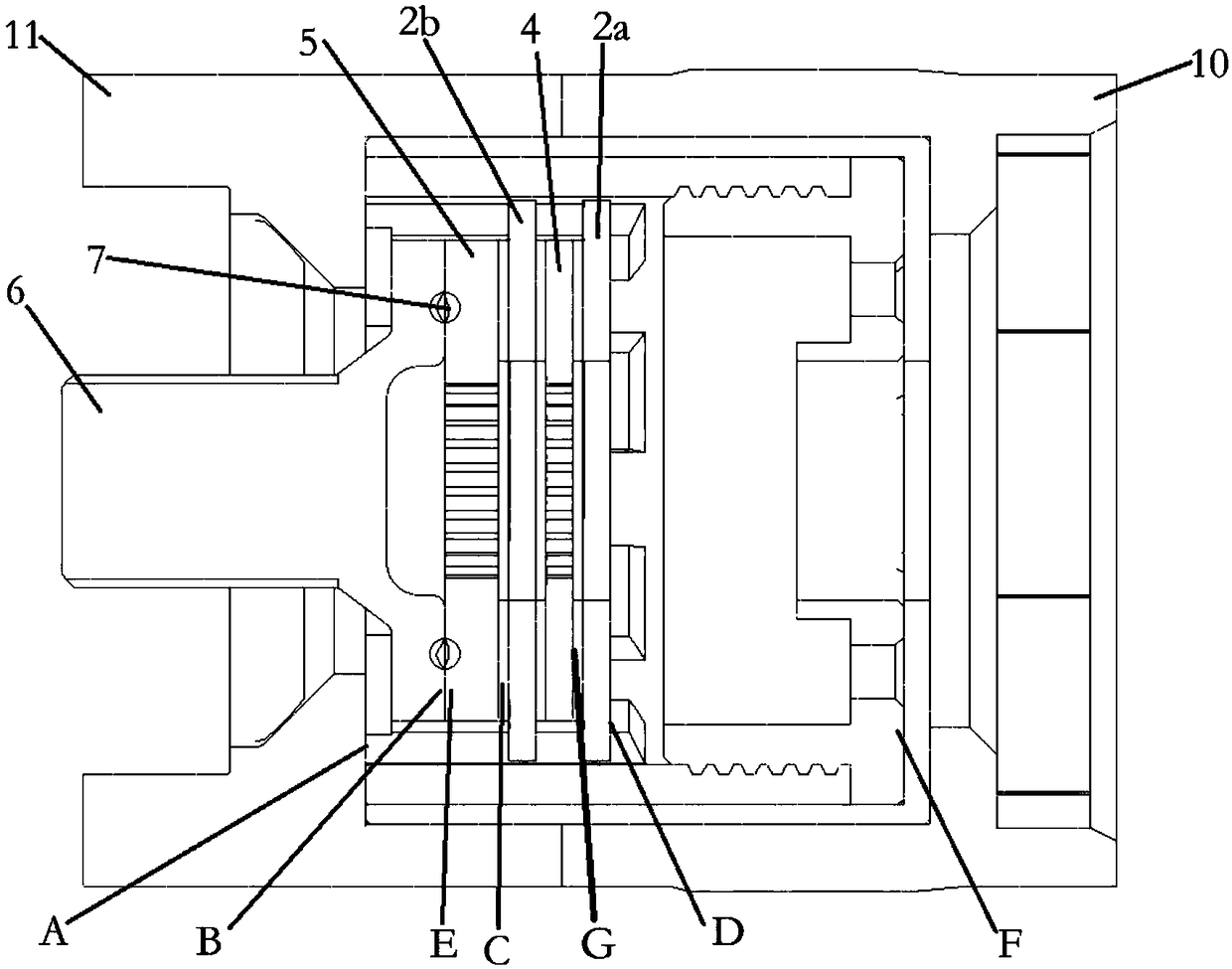

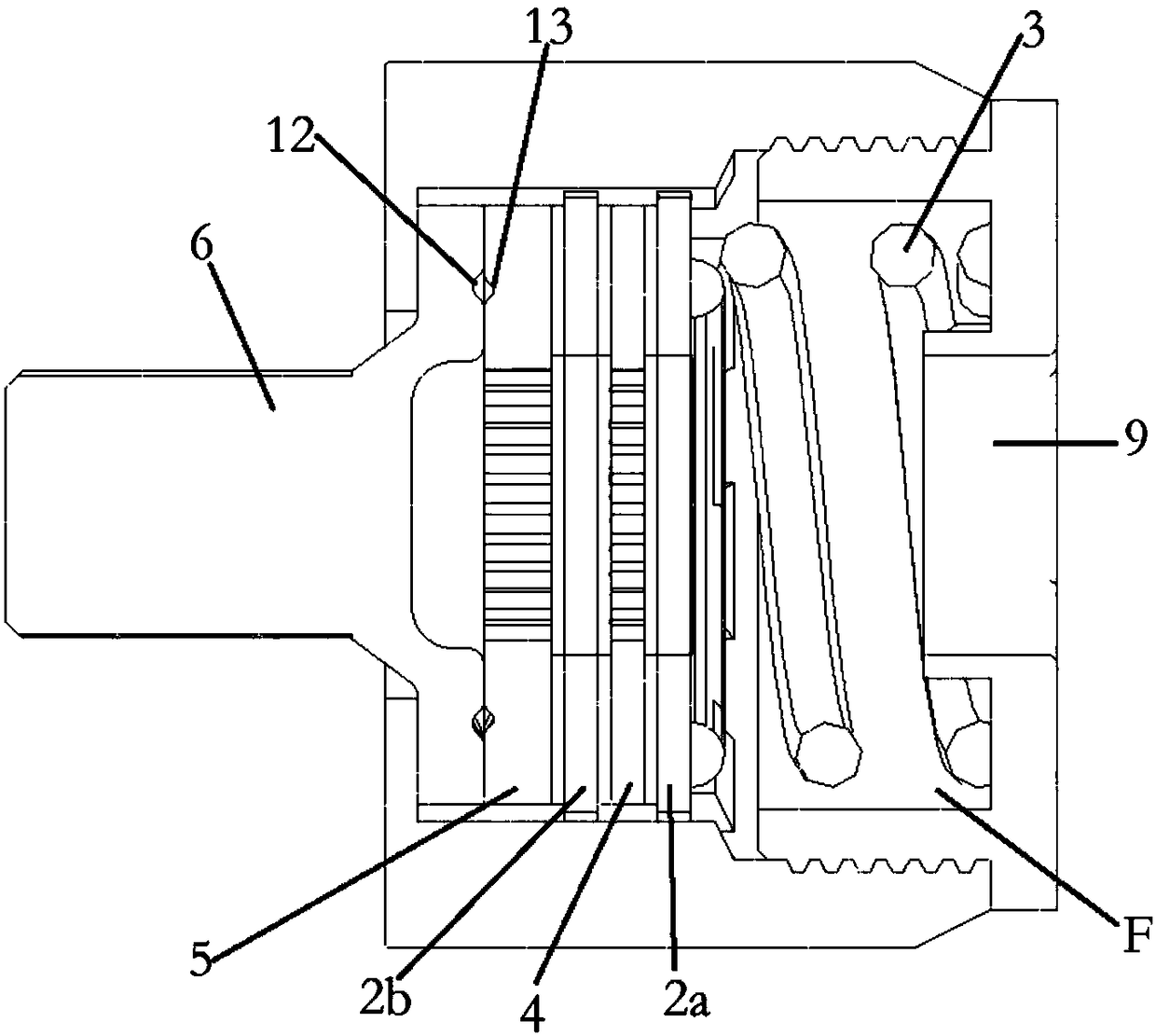

[0048] see Figure 1 to Figure 11 , an embodiment of a damper for overload protection provided in the embodiment of the present invention, including: a damper housing 1, a fixed plate 2, an elastic component, a friction plate 4, an overload friction block 5, an overload adapter seat 6 and an overload steel ball 7. The damper shell 1 defines the damper cavity 8; the first side B of the overload adapter seat and the second side E of the overload friction block are provided with a cavity for accommodating the overload steel ball 7; the overload steel ball 7 is arranged in the cavity , and the overload adapter 6 is arranged on the first side A of the damper cavity so that the overload adapter 6 rotates around the rotation axis 9 of the force out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com