Drying device based on swing type air guide plate

A drying device and air deflector technology, applied in drying, drying machine, drying gas arrangement, etc., can solve problems such as slow start-up speed, large energy consumption, and long warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific examples. The examples are implemented on the premise of the technical solutions of the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

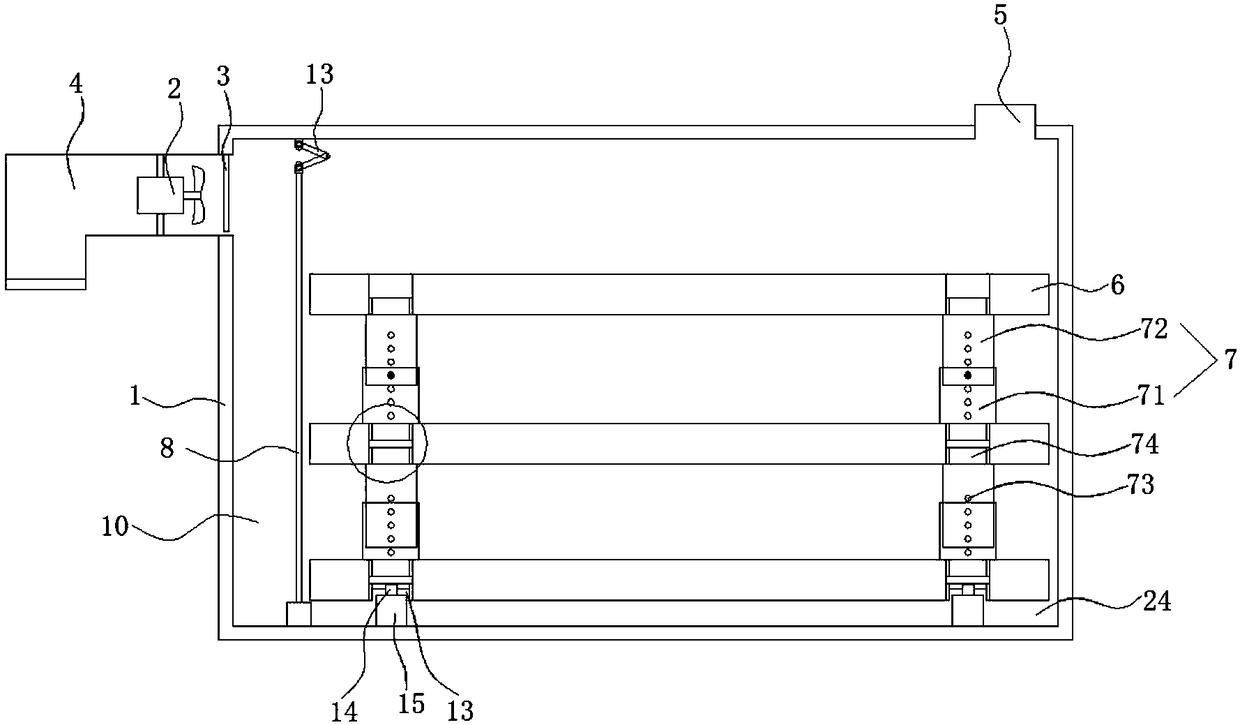

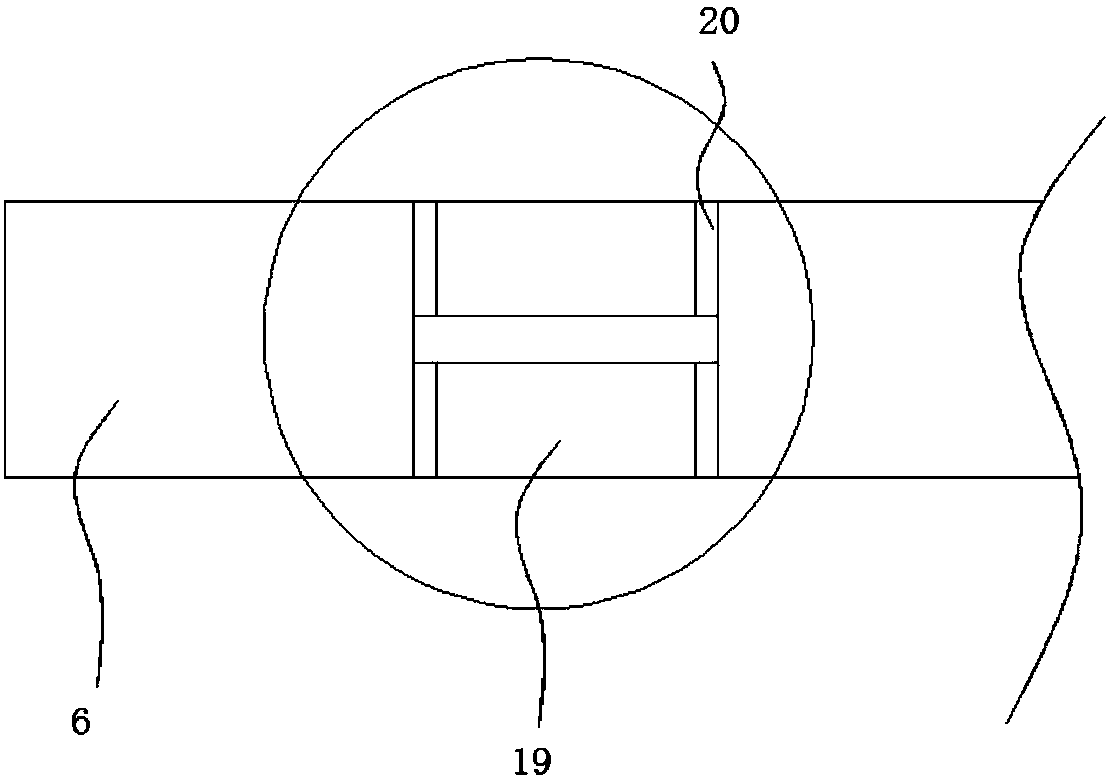

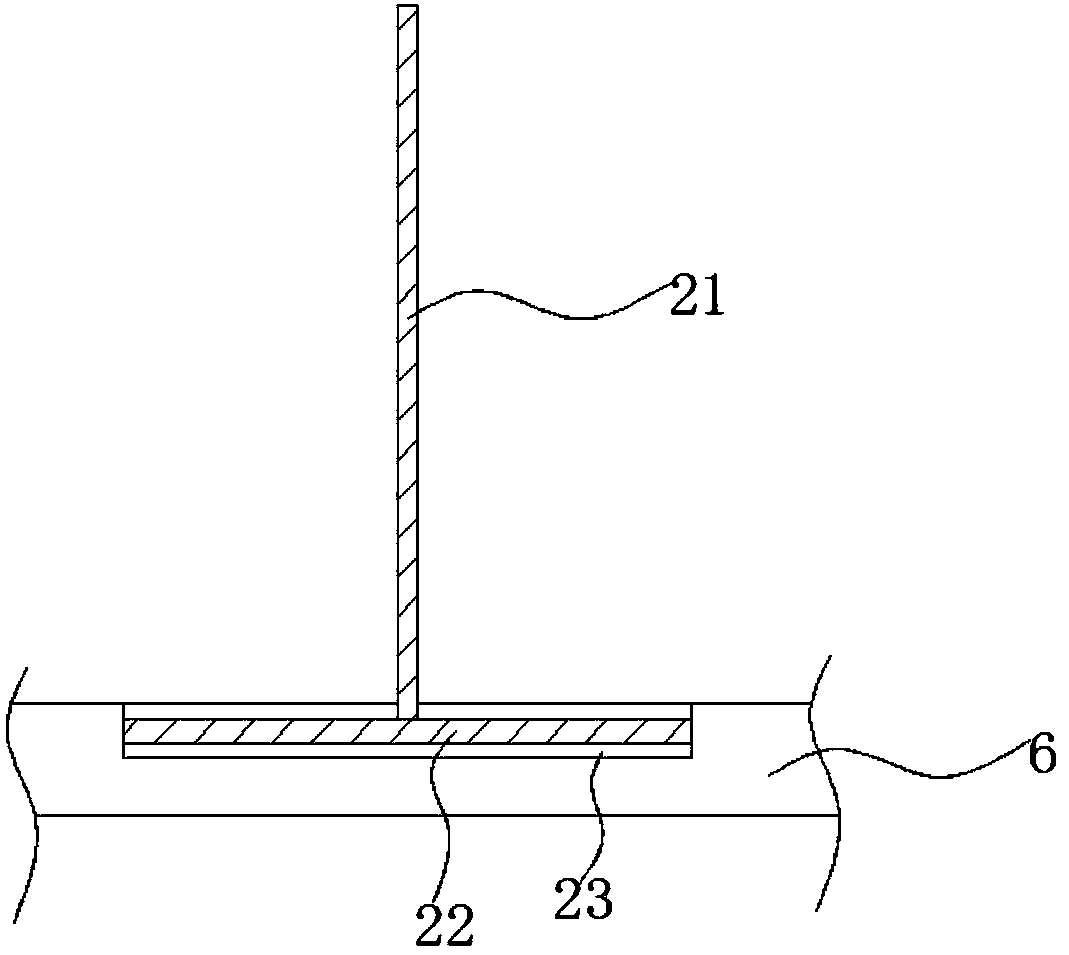

[0023] Such as Figure 1 to Figure 6 As shown, a drying device based on a swinging air deflector includes a box body 1, a fan 2, a heater 3, an air inlet 4 and an air outlet 5, and the air inlet 4 is arranged on the upper part of the side wall of the box body 1, and the The inlet of the tuyere 4 is set downward, the air outlet 5 is set on the top of the box 1 close to the other side wall of the box 1, the heater 3 is a heating resistor, and the heating resistor is located inside the fan 2, and the front side of the box 1 is also set There is a box door 24 that can open and close the box body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com