A resonance smoke box and its method for enhancing heat exchange

The technology of a smoke box and a resonance cavity is applied in the field of resonance smoke box and its enhanced heat exchange, which can solve the problems of the reduction of heat exchange efficiency of smoke pipes, the limitation of heat exchange efficiency by the flow rate of flue gas, and the inability to apply to large-diameter smoke pipes, etc. To achieve the effect of easy adjustment of flue gas heat exchange efficiency, simple structure and good self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

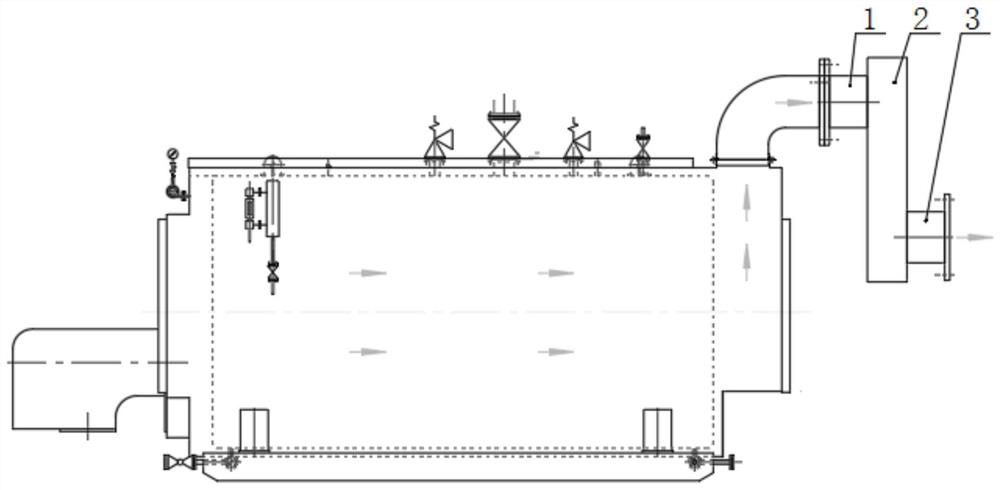

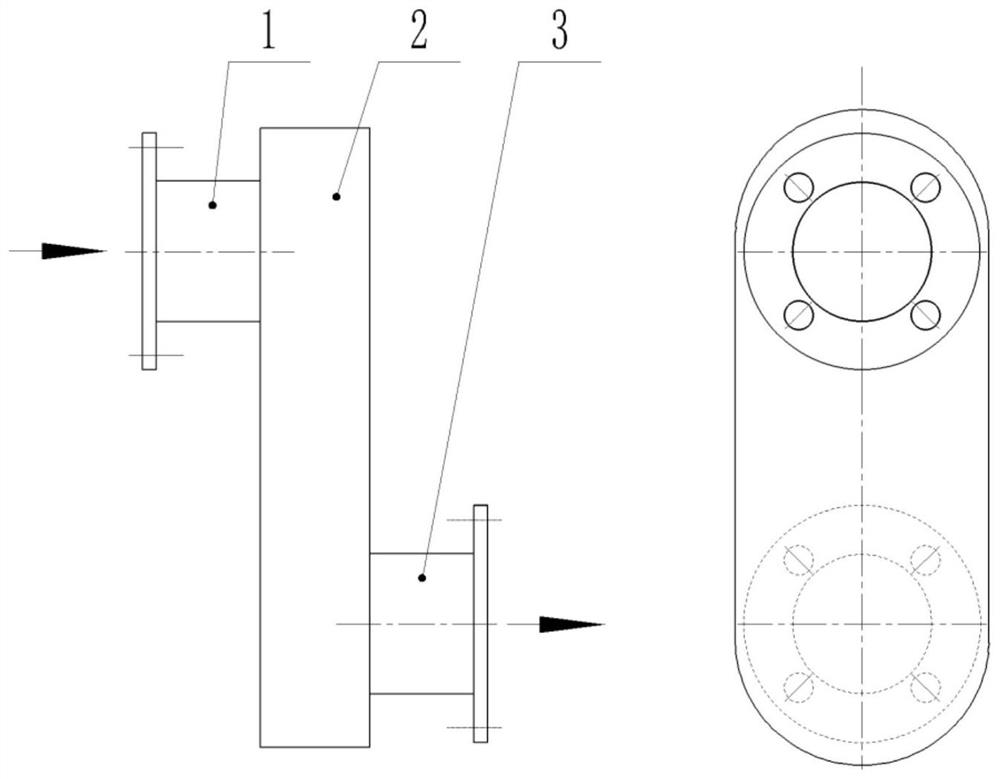

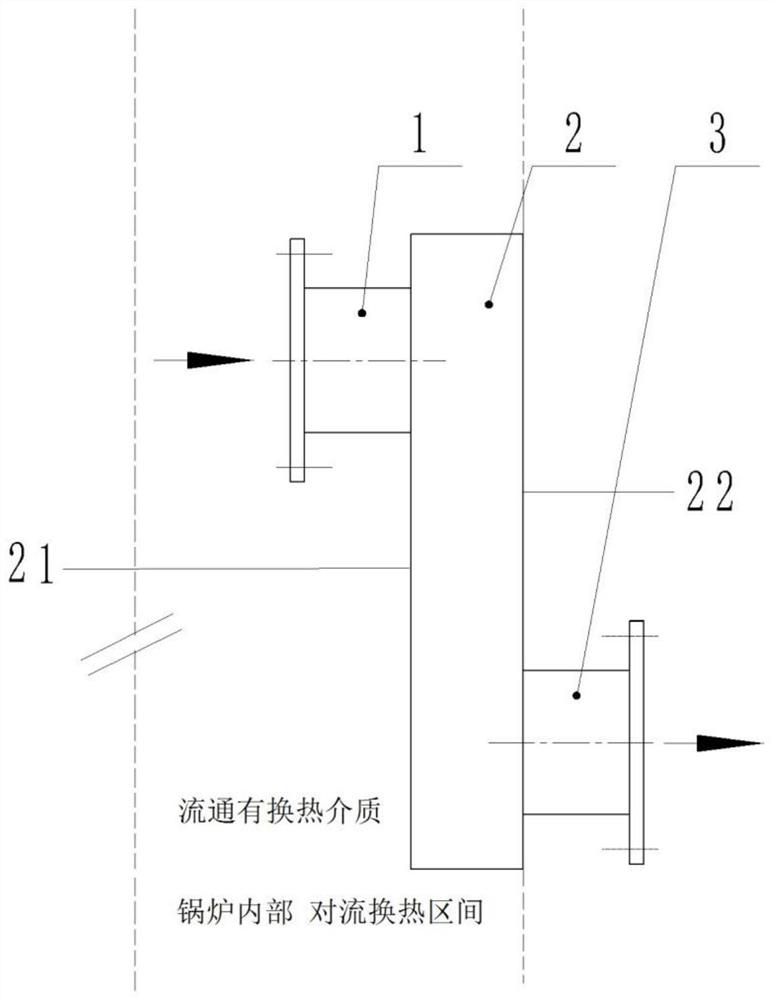

[0087] Such as figure 1 As shown, a resonance smoke box and a heat exchange method using the resonance smoke box, the resonance smoke box is connected to the convection heat exchange device (mainly heat exchange tube) inside the boiler and the flue gas used to transport flue gas and tail gas outside the boiler The resonant smoke box includes the flue gas inlet 1, the flue gas outlet 3, and the resonance cavity 2 between them. The high-temperature flue gas circulates in the heat exchange tube, and the flue gas tail gas formed after convective heat exchange passes through the flue gas. The inlet 1 enters the resonance cavity 2, and enters the flue through the flue gas outlet 3. Wherein, all parts of the resonant cavity 2 enter into the convective heat exchange section of the boiler, and cold water circulates between the heat exchange tubes and the external of the resonant cavity 2 .

[0088] The resonance smoke box is made of alloy steel as a whole, and the cross-sectional area o...

Embodiment 2

[0091] The structure and heat exchange method of the resonant smoke box are consistent with the embodiment 1, the only difference is that a row of reinforcing ribs are respectively arranged in the length direction (horizontal direction) and width (longitudinal) direction of the rear wall surface 22, and the material of the reinforcing ribs is alloy steel. Two rows of reinforcing ribs respectively extend from the middle of the length and width of the rear wall 22, dividing the rear wall 22 into four parts.

[0092] The width of the reinforcing rib in the length direction is 0.05m, and the thickness is 0.04m; the width of the reinforcing rib in the width direction is 0.04m, and the thickness is 0.04m.

Embodiment 3

[0094] The structure and heat exchange method of the resonant smoke box are consistent with Embodiment 1, the only difference is that, as Figure 4 As shown, three rows of reinforcing ribs are evenly arranged in the length direction (horizontal direction) and width (longitudinal) direction of the rear wall surface 22 respectively, and the material of the reinforcing ribs is aluminum.

[0095] In the length direction, the rib in the center has a width of 0.06m and a thickness of 0.04m; the ribs on both sides have a width of 0.05m and a thickness of 0.02m.

[0096] In the width direction, the rib in the center has a width of 0.05m and a thickness of 0.04m; the ribs on both sides have a width of 0.04m and a thickness of 0.02m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com