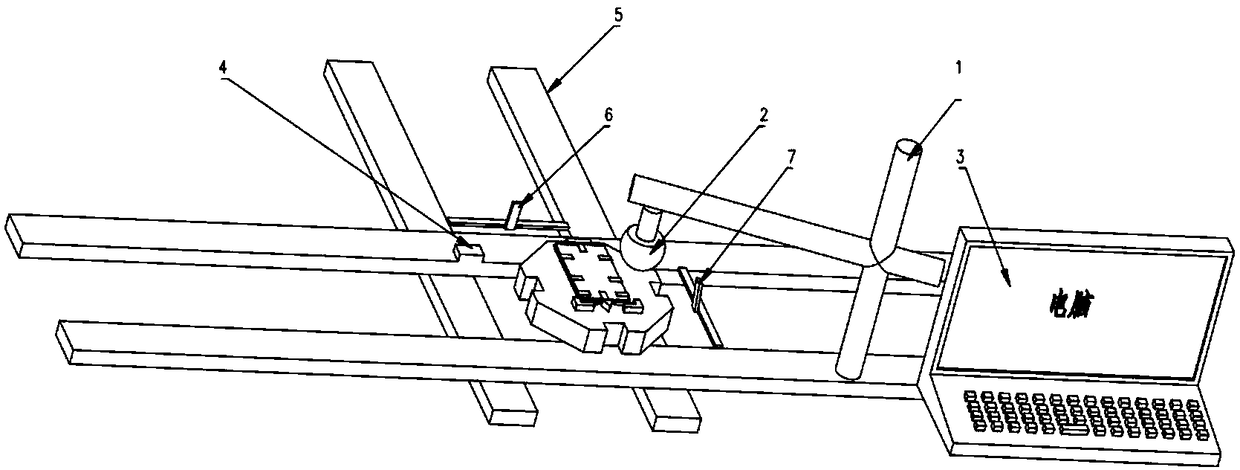

Method and device for testing coating condition of laminated chip pole piece

A laminated battery technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of large space occupation, inability to apply assembly line online detection, low efficiency, etc., and achieve the effect of improving battery safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

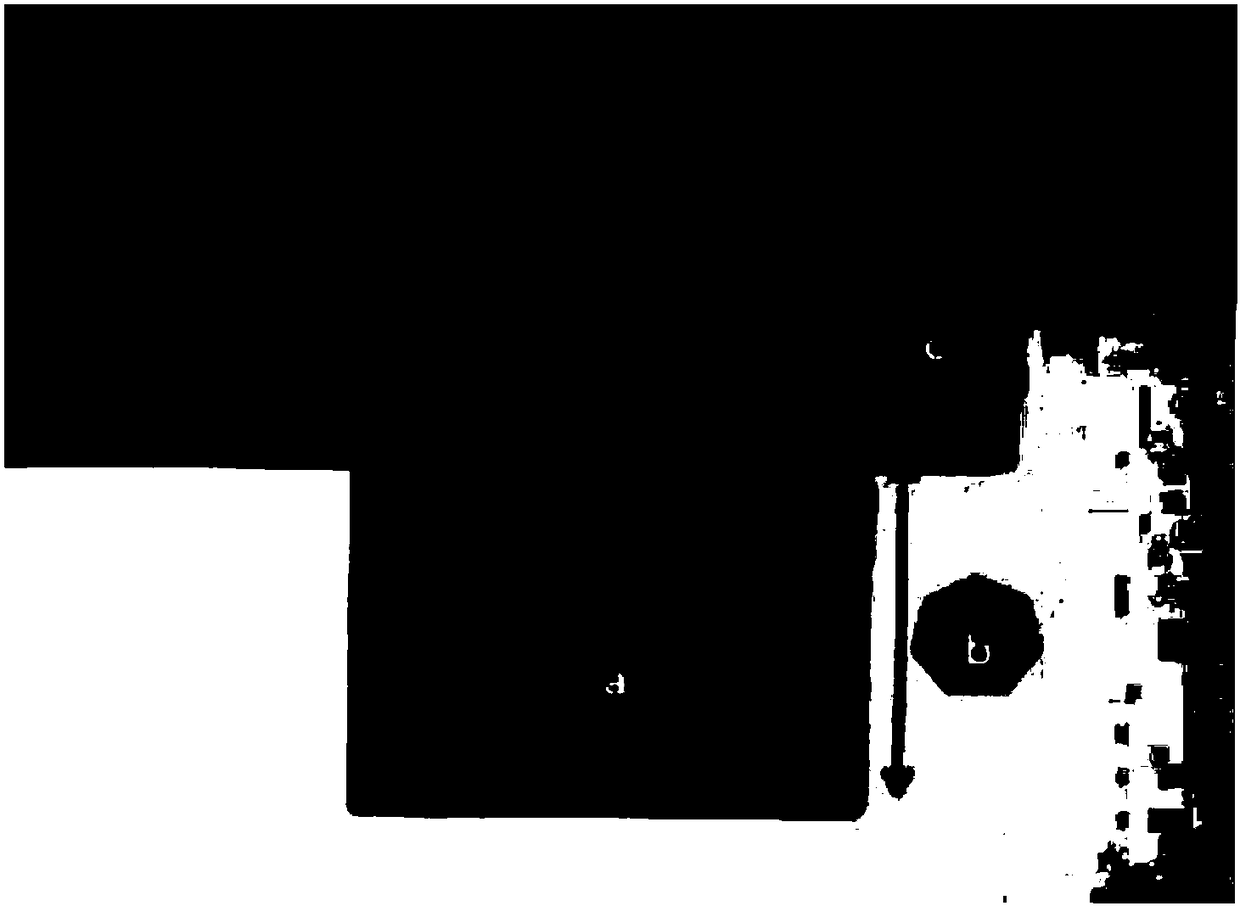

[0031] When the positive and negative pole pieces are stacked together, all the tabs of the positive pole pieces will completely overlap, and the tabs of the negative pole pieces will overlap together as a whole. When there is one or more pole pieces misaligned left and right between the tab layers, and there is an offset, the width dimension of the tab layer a>standard value; when there is one or more pole pieces offset upwards between the tab layers, the tab is exposed The length dimension b> standard value; when the pole piece of the tab layer deviates downward as a whole, the exposed length dimension b of the tab < the standard value; if the width direction of the separator and the negative electrode piece is poorly covered, the shoulder width c < the standard value.

Embodiment 2

[0033] Take 100 batteries to flow through the testing equipment on the assembly line, 15 of them are selected to the poorly coated area, measure the dimensions a, b, and c of the tabs of each defective battery, and at least one value is inconsistent with its standard value; Randomly select 15 normal batteries, and measure the dimensions a, b, and c of the tab positions, which are all consistent with the standard values.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com