A kind of preparation method of skin sensor based on sacrificial layer technology and prepared product

A sacrificial layer and sensor technology, applied in the direction of sensors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of easy deformation of skin sensors, damage to sensor structure, and inability to use, etc., to achieve low price, ensure safety, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

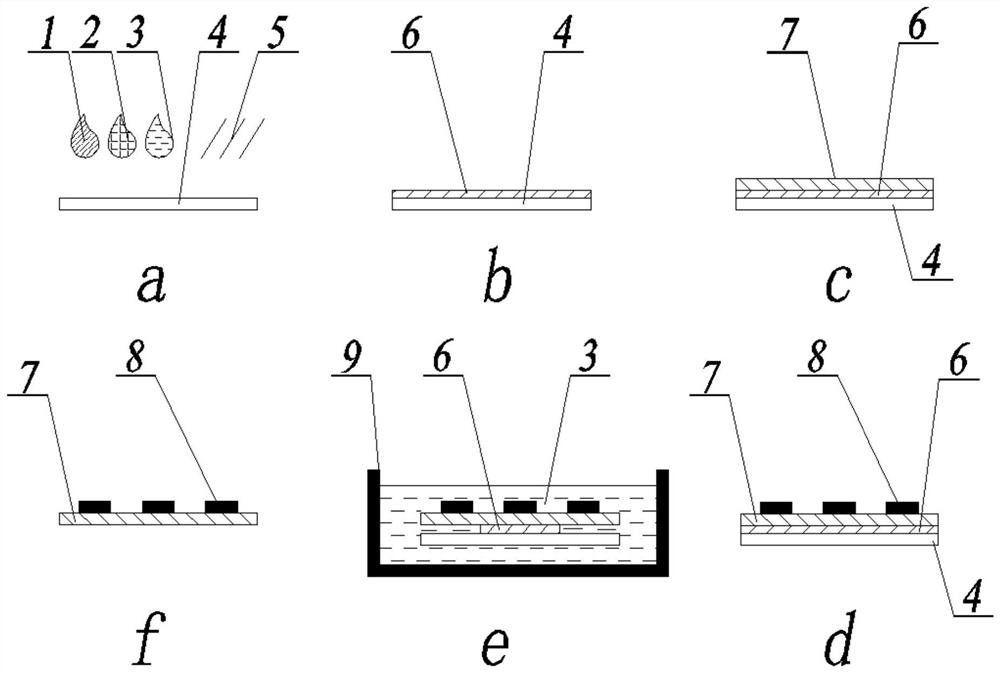

[0036] According to one aspect of the present invention, as figure 1 As shown, the present invention provides a method for preparing a skin sensor based on sacrificial layer technology, comprising the following steps:

[0037] In step (1), polyvinyl alcohol powder is added into deionized water 3 to dissolve, and configured into a polyvinyl alcohol solution, which is left to stand for later use. Preferably, the mass fraction of polyvinyl alcohol in the polyvinyl alcohol solution is 8-12%. The configuration method of the polyvinyl alcohol solution is as follows: use a balance to weigh a predetermined mass of polyvinyl alcohol powder, then use a measuring cylinder to measure a predetermined volume of deionized water 3 and pour it into a beaker, and then slowly add the polyvinyl alcohol powder into the beaker , and stir with a glass rod at the same time; after mixing evenly, put magnetic beads into the solution and stir for 4 to 6 hours on a magnetic stirrer, while heating to pro...

Embodiment 1

[0056] a Select a 4-inch monocrystalline silicon wafer as the hard substrate 4, and use acetone 1, isopropanol 2, and deionized water 3 to ultrasonically clean the polished surface of the silicon wafer in sequence. The cleaning time of each reagent is 2 minutes, and finally use nitrogen gas 5 Dry the surface and let it stand for later use.

[0057] b Spin-coat a polyvinyl alcohol solution with a mass fraction of 10% on the hard substrate 4 at a spin-coating speed of 500 rpm and a spin-coating time of 5 minutes. Then put the hard substrate 4 on a hot plate and heat it at 80° C. for 20 minutes, so that the water is heated and evaporated, and the polyvinyl alcohol is cured to form a film, and the preparation of the sacrificial layer is completed. Among them, the manufacturer of polyvinyl alcohol is Shanghai Chenqi Chemical Technology Co., Ltd., the model is PVA1788, the degree of polymerization is 1650-1850, and the degree of alcoholysis is 88%.

[0058] c Spin-coat polydimethyl...

Embodiment 2

[0064] a Select a 4-inch monocrystalline silicon wafer as the hard substrate 4, and use acetone 1, isopropanol 2, and deionized water 3 to ultrasonically clean the polished surface of the silicon wafer in sequence. The cleaning time of each reagent is 2 minutes, and finally use nitrogen gas 5 Dry the surface and let it stand for later use.

[0065] b The material and preparation method of the sacrificial layer are the same as in Example 1.

[0066] c Spin-coat platinum-catalyzed silicone rubber on the polyvinyl alcohol sacrificial layer 6 as the substrate of the sensor, the spin-coating speed is 800 rpm, and the spin-coating time is 3 minutes, and then it is cured at room temperature for 2 hours to obtain Flexible base7. The model of platinum-catalyzed silicone rubber is Ecoflex 00-30, and the mass ratio of the two components is 1:1. The thickness of the substrate under this condition was 50 micrometers.

[0067] d Integration of the sensor element 8 on the flexible substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com