Nozzle structure for spraying concrete

A technology of shotcrete and concrete, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of increasing the rebound amount of concrete, affecting the construction environment, and not being able to solidify quickly, so as to reduce the rebound amount, speed up the mixing efficiency, improve the The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

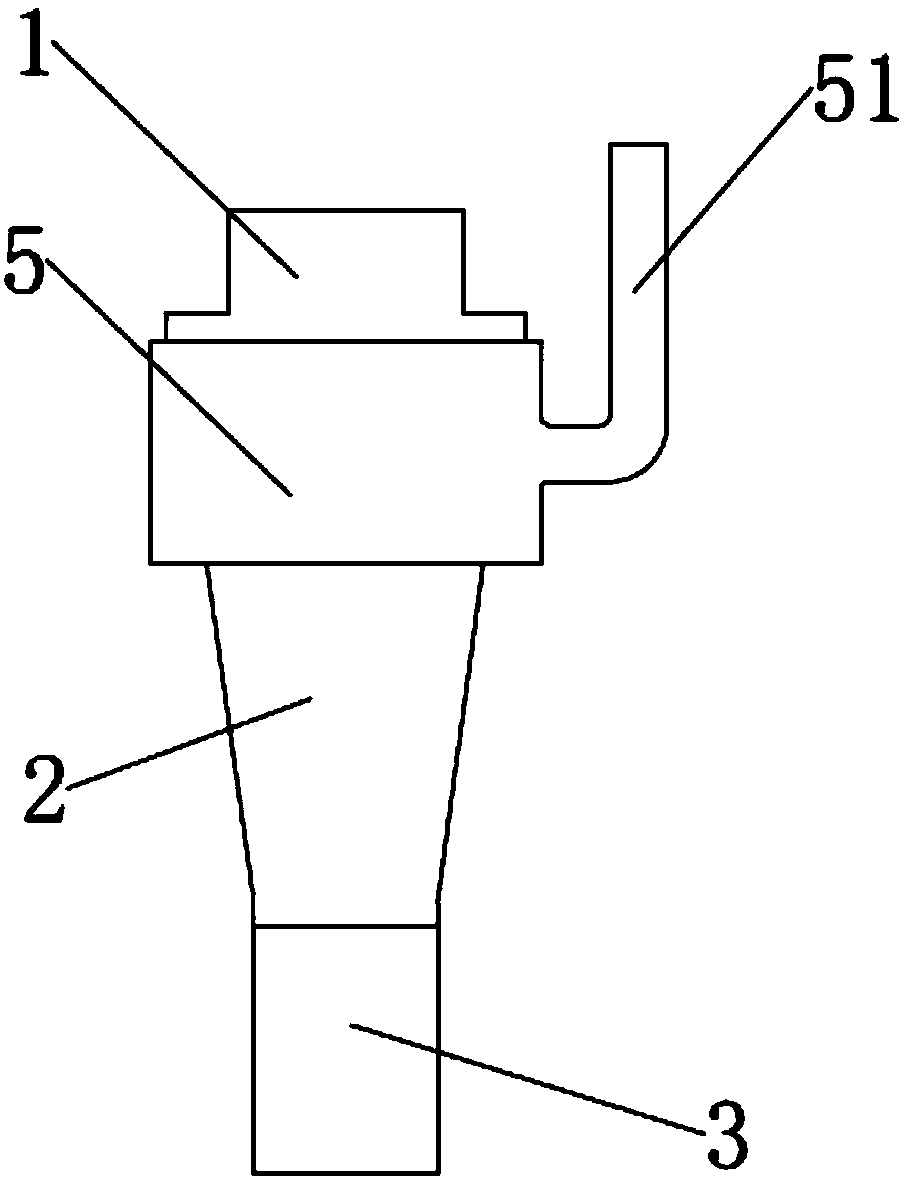

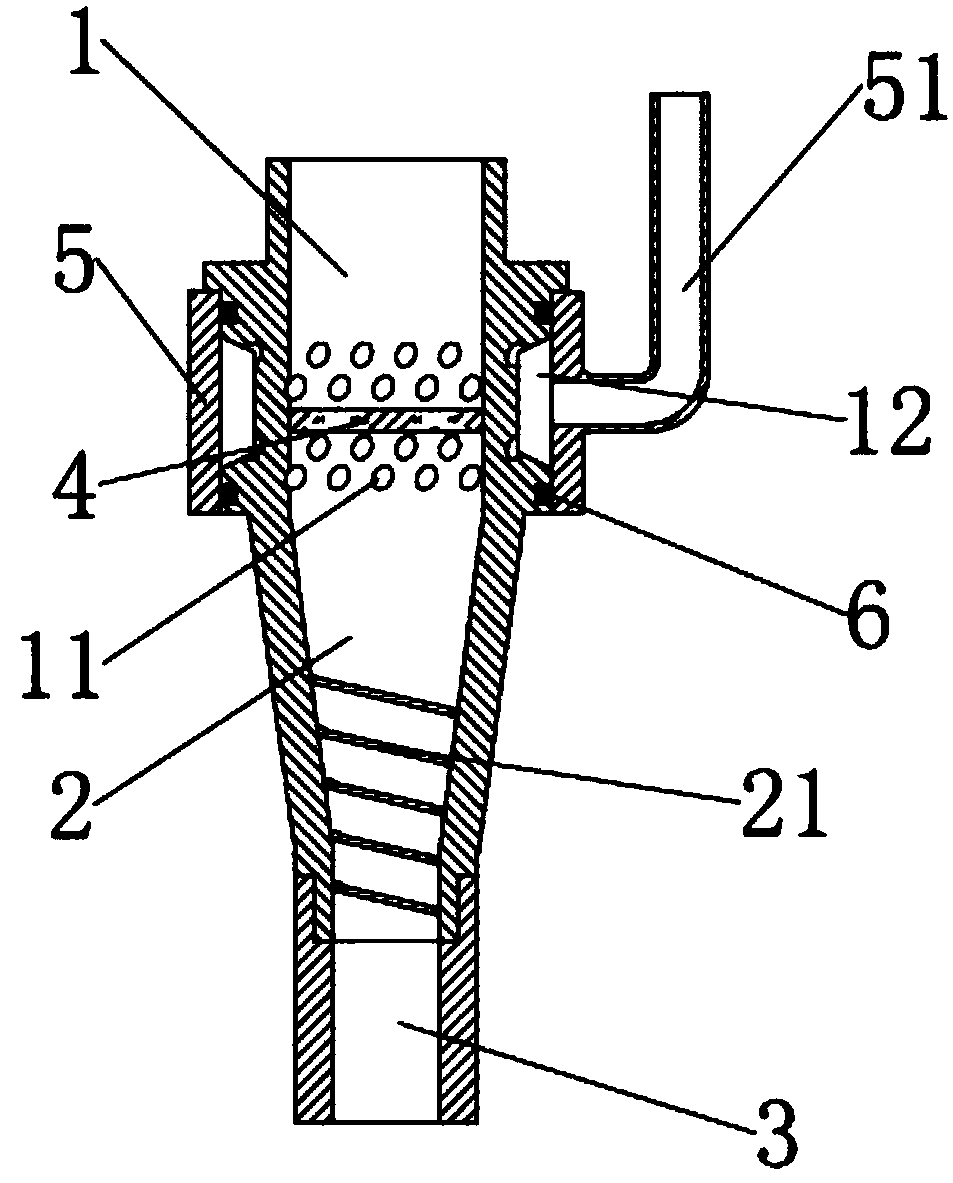

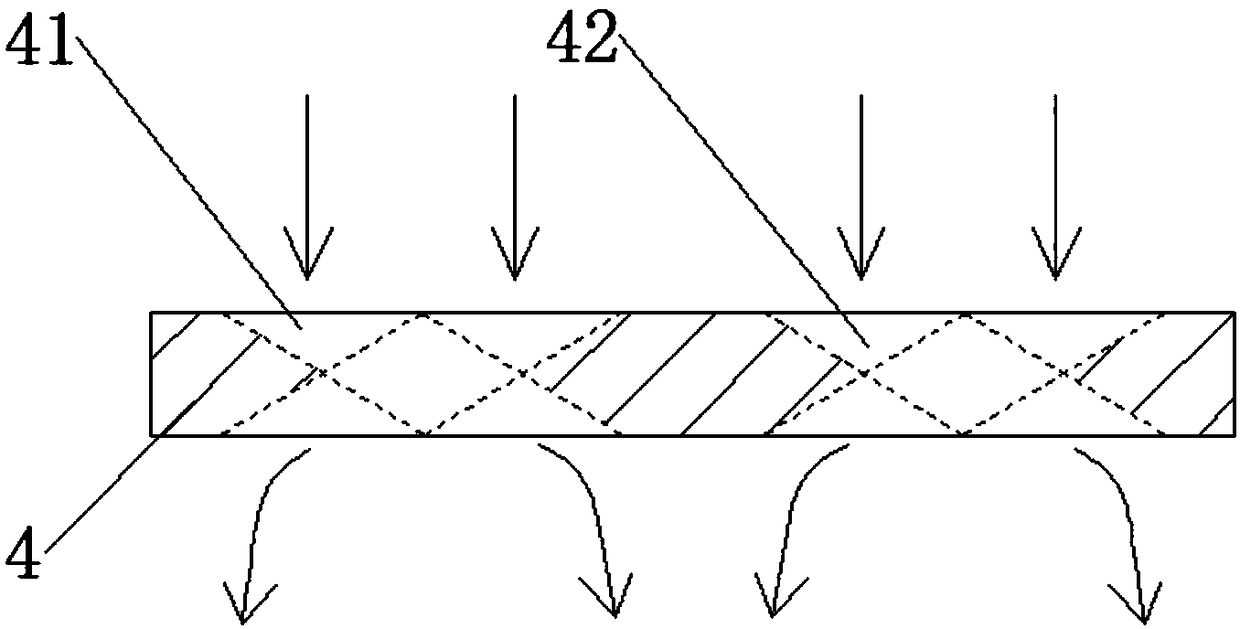

[0023] Embodiments of the present invention are as follows: Figure 1~4 As shown, a nozzle structure for spraying concrete includes a first mixing pipe 1, a second mixing pipe 2 and a spray pipe 3 connected to the concrete delivery pipe in sequence, and the side wall of the first mixing pipe 1 is provided with a Accelerating agent and air pass into a plurality of first through holes 11 in the pipe, and a drainage plate 4 is arranged between the corresponding plurality of first through holes 11 in the first mixing tube 1, and the drainage plate 4 is provided with circularly arranged through holes. The hole unit, the through hole unit includes a second through hole 41 extending from the outside of the upper surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com