Chassis structure for AGV (Automated Guided Vehicle)

A chassis and chassis frame technology, applied in the field of chassis structure, can solve the problems that cannot cope with the undulating road surface and affect the running accuracy of AGV vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

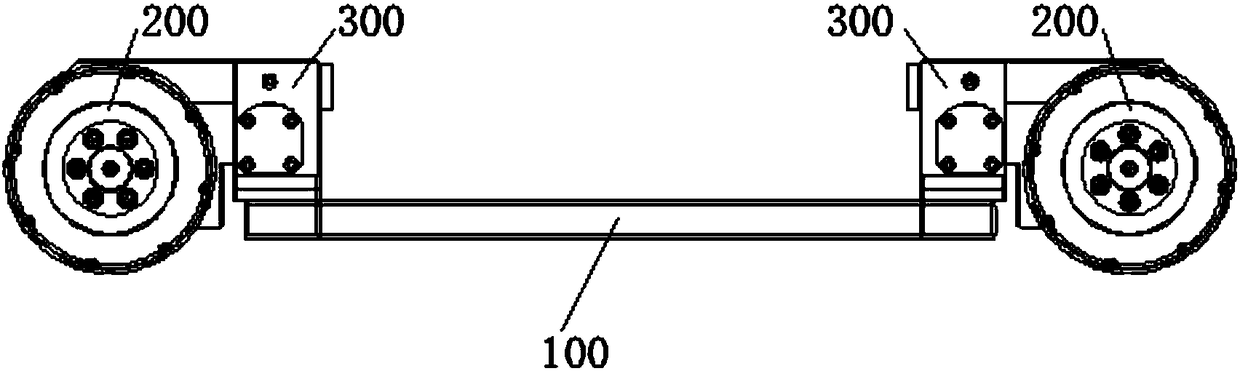

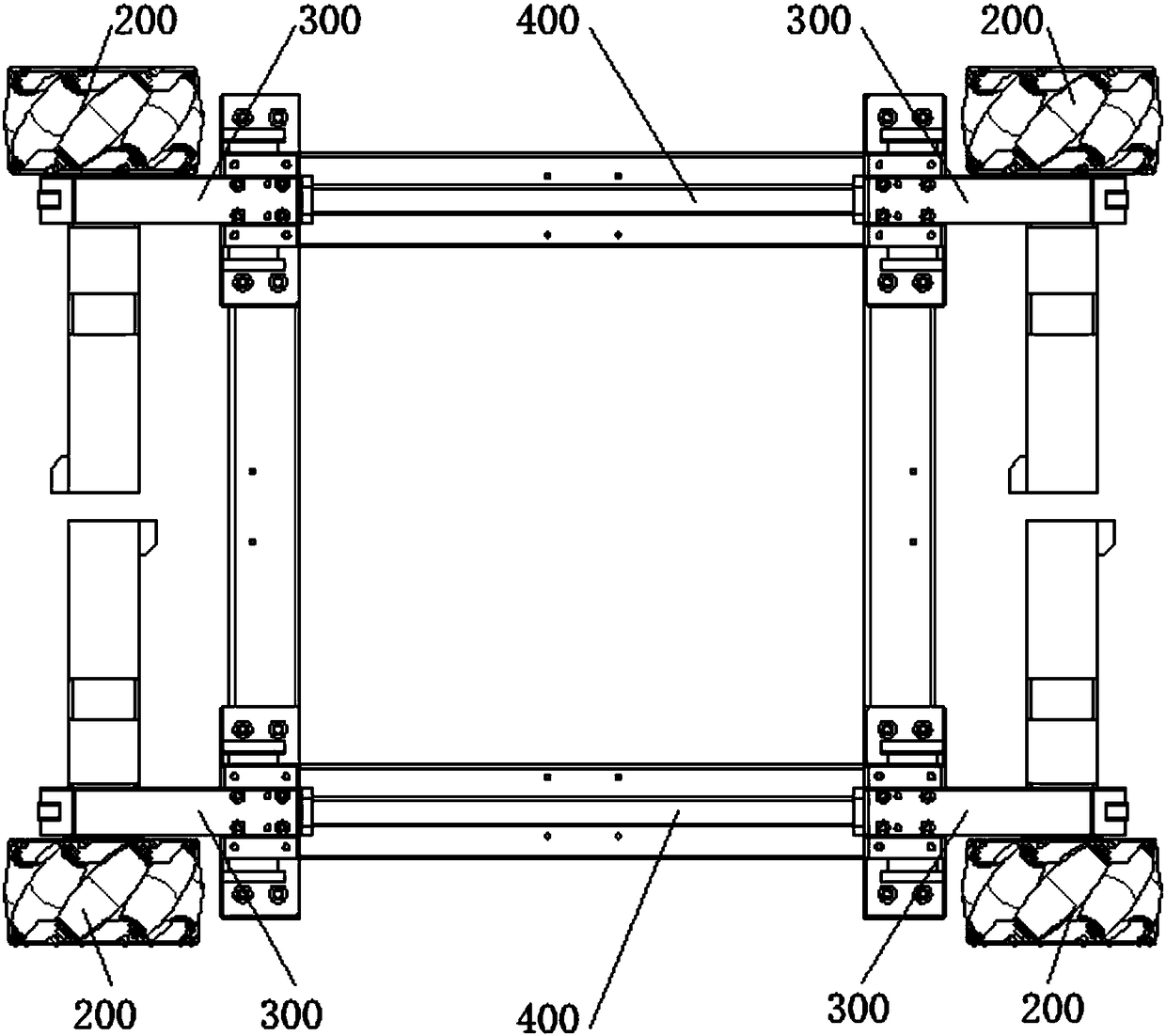

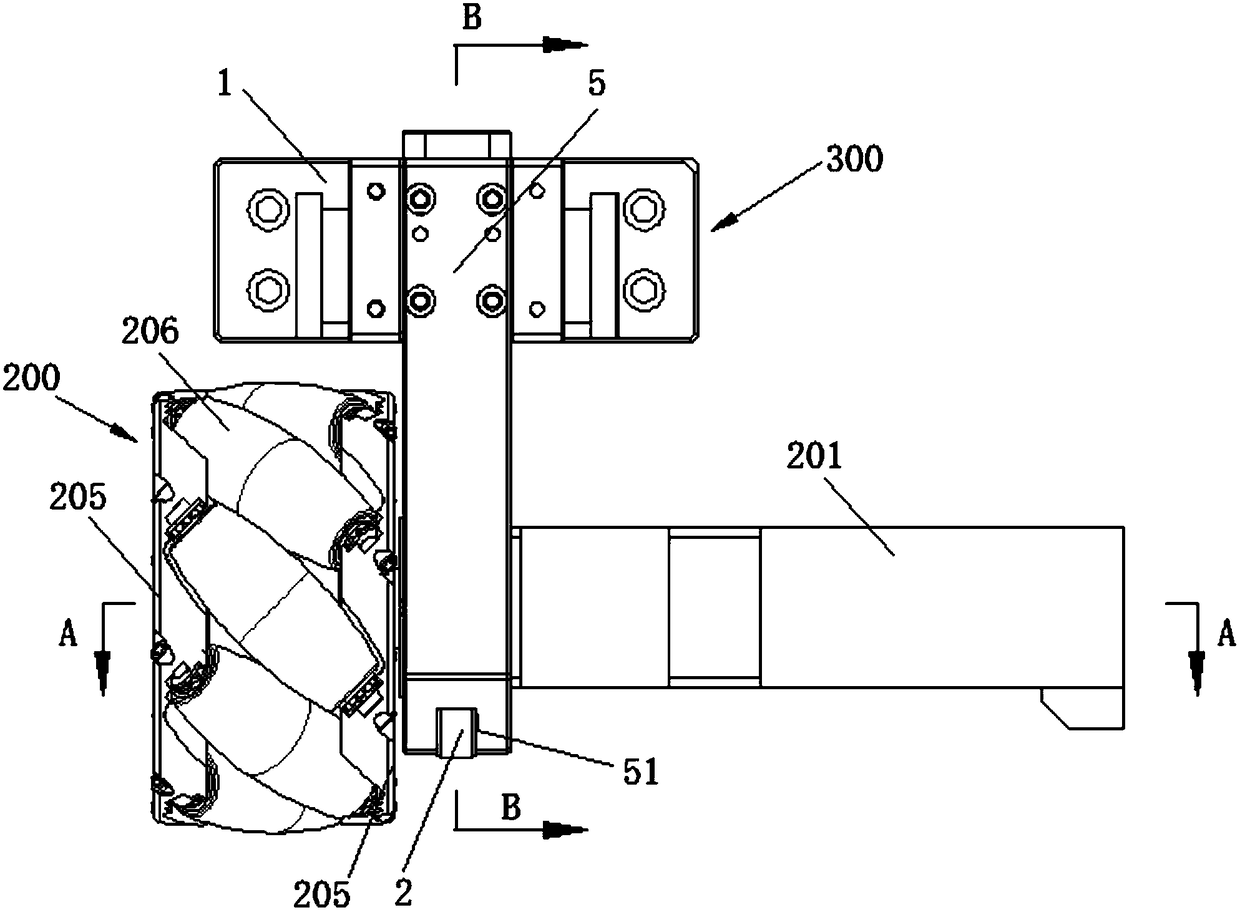

[0020] see Figure 1-6 As shown, a chassis structure of an AGV includes a quadrangular chassis frame 100, the four corners of the chassis frame 100 are provided with Mecanum wheel assemblies 200, and the four corners of the chassis frame 100 Each place is provided with a suspension mechanism 300, the suspension mechanism 300 includes a mounting seat 1, a swing plate 2, a swing pin 3, a spring 4 and a limit plate 5, and the mounting seat 1 is fixedly connected to the corner of the chassis frame 100, And the swing plate 2 is rotatably connected to the mounting base 1 through the swing pin 3, one end of the spring 4 is connected to the mounting base 1, and the other end is connected to the swing plate 2, and one end of the limiting plate 5 is fixedly connected to the mounting base 1 , when the oscillating plate 2 is overloaded, the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com