Prefabricated slab pile construction locating frame and locating method

A positioning method and prefabricated plate technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problem of inability to prefabricate sheet pile limit or two-way limit, improve construction efficiency, wide application range, avoid position The effect of bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

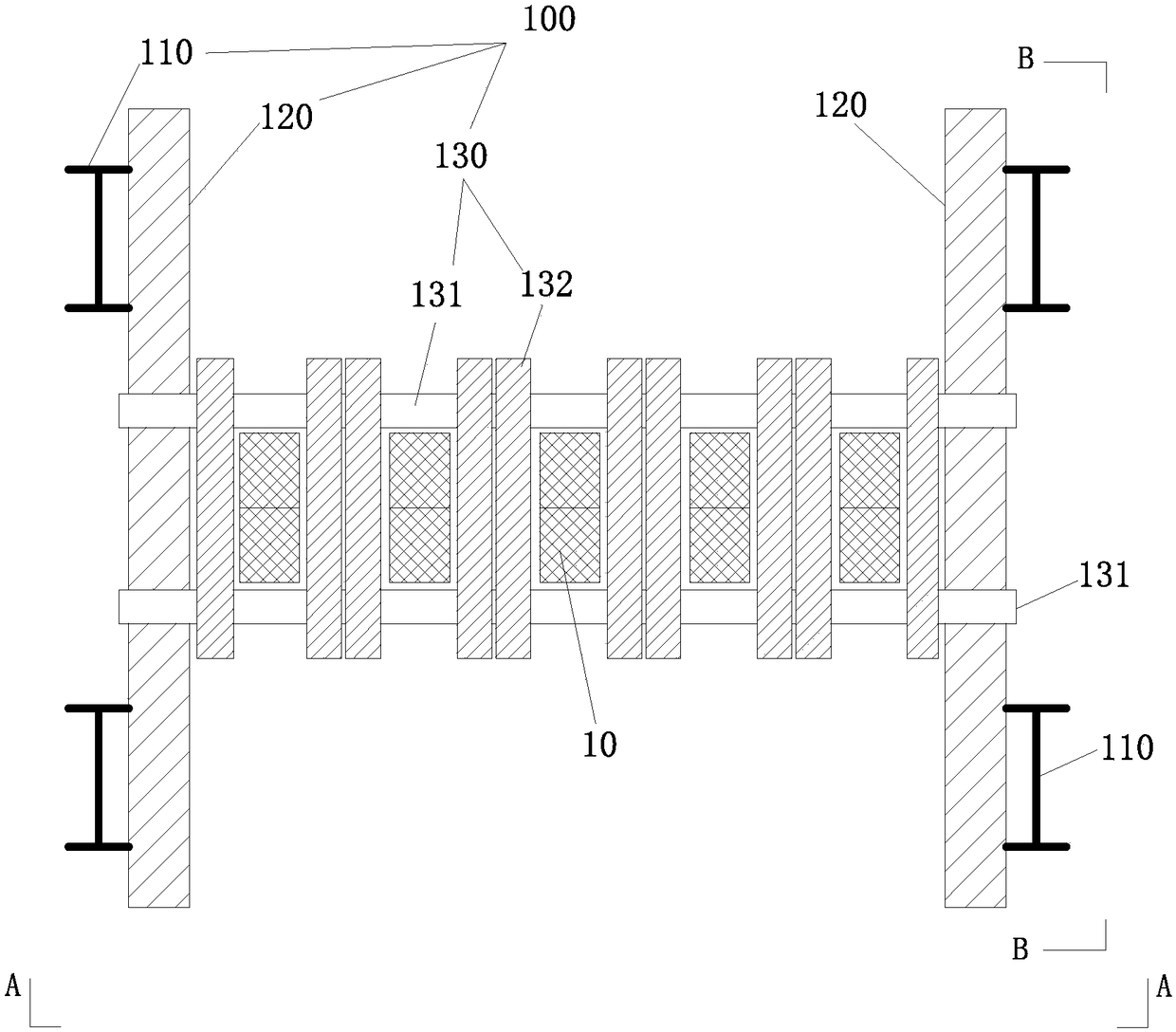

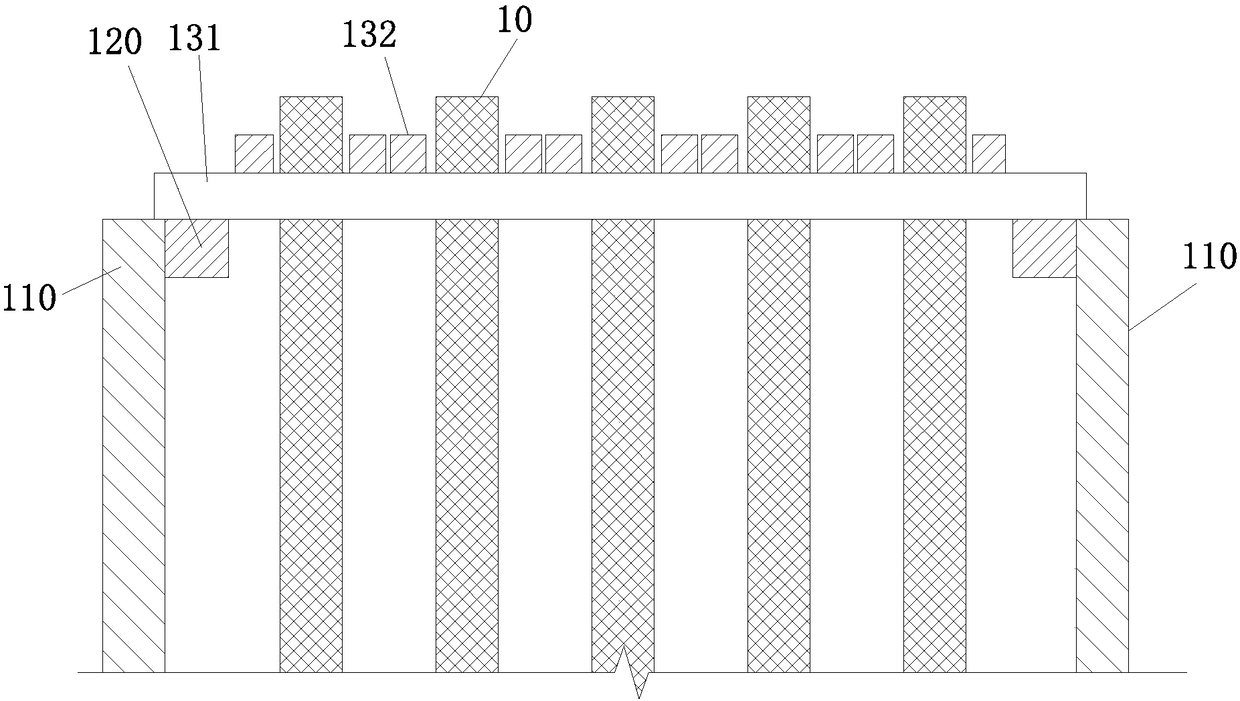

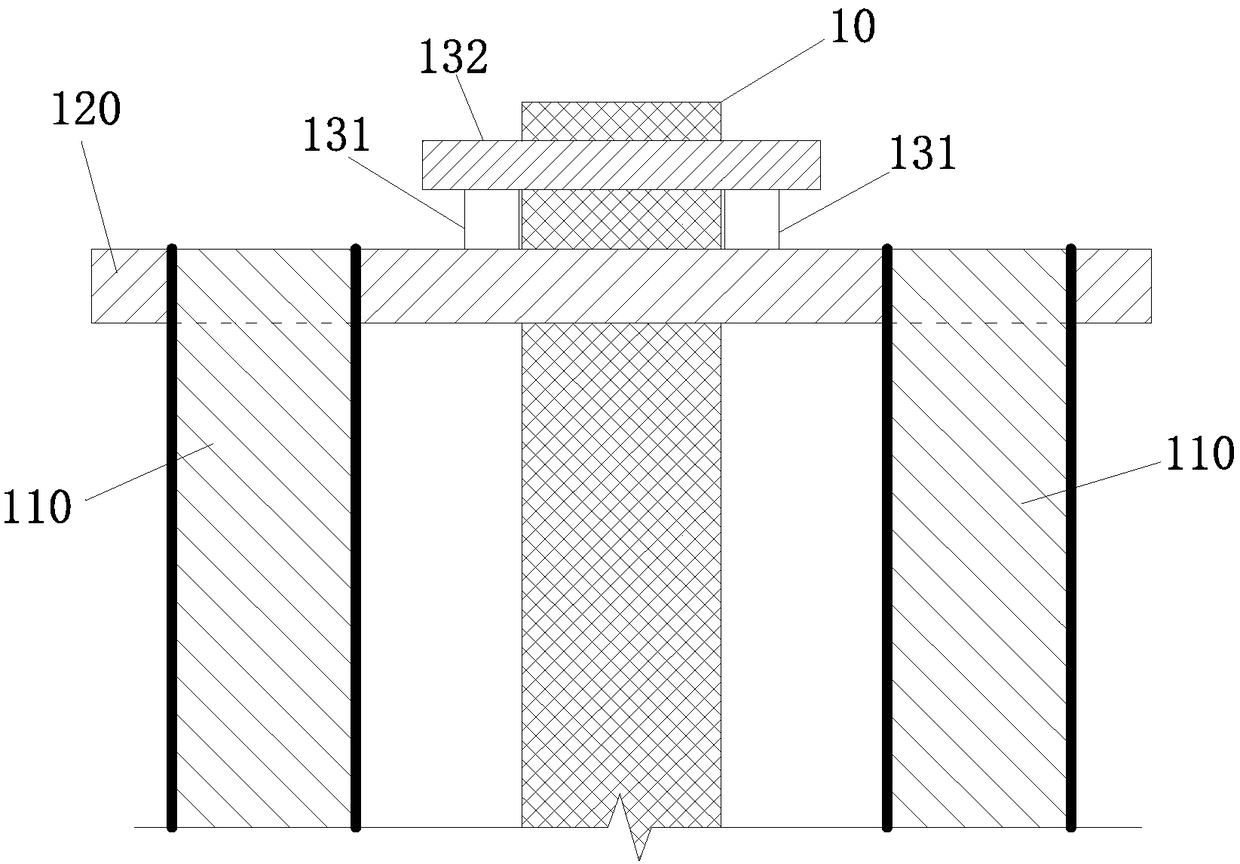

[0040] see Figure 1 to Figure 3 As shown, the prefabricated sheet pile construction positioning frame 100 in this embodiment includes two rows of four steel columns 110 , two steel crossbeams 120 and one stop component 130 . Wherein, the shaped steel columns 110 are arranged vertically, and each row of shaped steel columns 110 is respectively fixed with a horizontally arranged steel crossbeam 120, and the two steel crossbeams 120 are in the same horizontal plane. The limit assembly 130 includes two steel crosspieces 131 arranged at intervals in parallel and several steel vertical pieces 132 vertically arranged between the two steel crosspieces 131. The steel vertical pieces 132 and the steel crosspieces 131 form a plurality of limit frame, the size of the limiting frame matches the size of the prefabricated sheet pile 10, and the two ends of the steel crosspiece 131 are vertically fixed on the steel crossbeam 120 respectively. As an example, the steel column 110 adopts four ...

Embodiment 2

[0046] This embodiment provides a positioning method for the construction of prefabricated sheet piles 10 using the positioning frame 100 in Embodiment 1, combining Figure 1 to Figure 3 As shown, the construction method includes the following steps:

[0047] S1. Within 30 minutes after the construction of the mixing pile is completed, drive two rows of shaped steel columns 110 vertically into the mixing pile, and fix a steel beam 120 on each row of shaped steel columns 110, and the two steel beams 120 are in the same horizontal plane. The profiled steel columns 110 can be arranged as two in each row and four in total.

[0048] S2. Prepare the limiting component 130, and fix the limiting component 130 horizontally on the steel beam 120, and make the limiting frame 133 of the limiting component 130 be located directly above the position where the prefabricated sheet pile 10 is to be constructed. The preparation method of the limit assembly 130 is to arrange two steel crosspiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com