Non-equal-arm-length two-way automatic tensioning wheel

A technology of tensioning wheel and non-equal arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

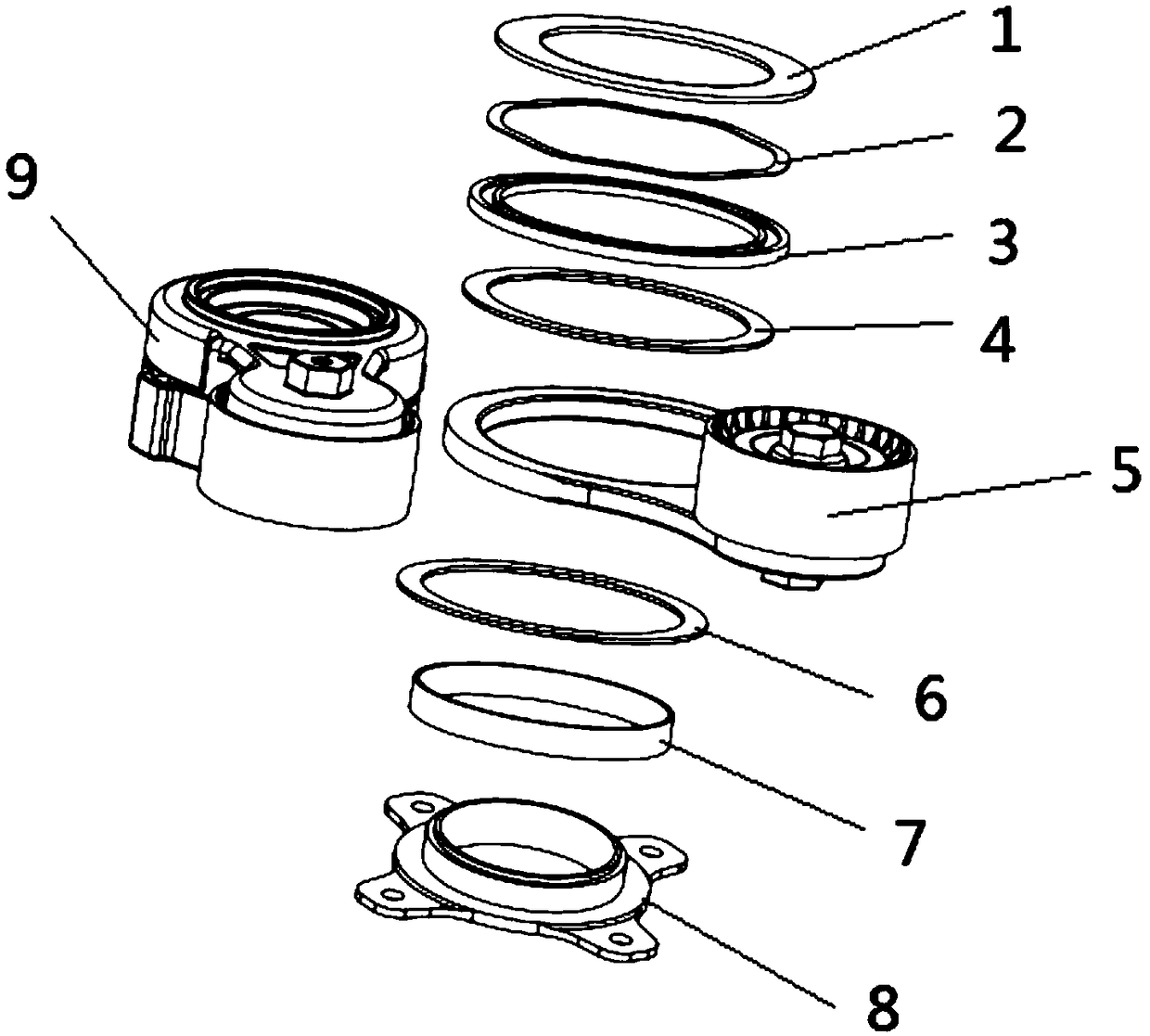

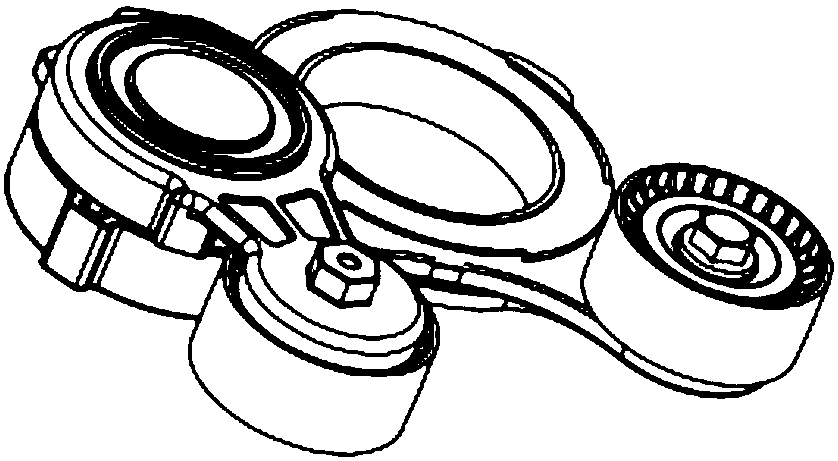

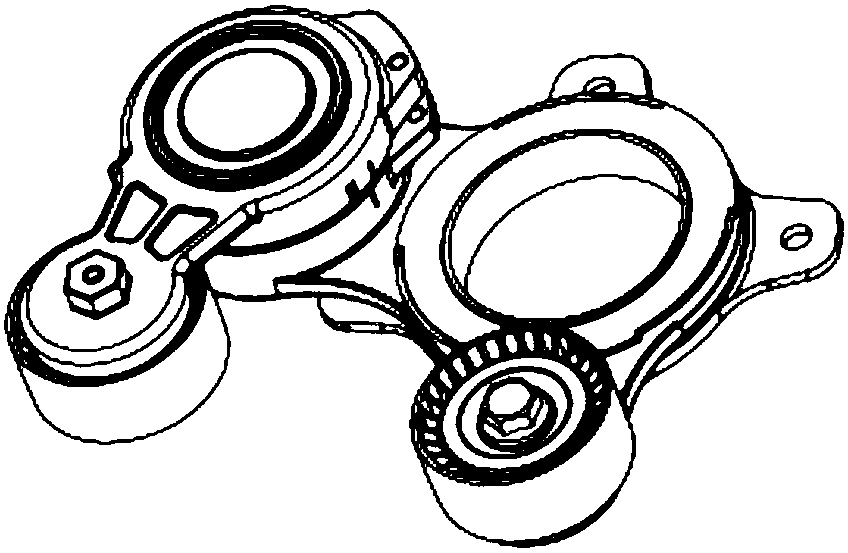

[0024] Such as Figure 1-3 As shown, the present embodiment discloses a non-equal length two-way automatic tensioning wheel, which consists of a base 8, a one-way automatic tensioning wheel assembly 9, a rocker arm assembly 5, a sliding bearing 7, a damping sheet I, a damping Sheet II, secondary spring cage 3, secondary spring 2, and cover plate 1 are assembled.

[0025] Base 8: it is the carrier of all parts of the tensioning wheel, and its end can be connected with the front housing of the opponent's intelligent motor at the same time, and is used to install and fix the two-way tensioner on the motor.

[0026] Sliding bearing 7: installed on the central cylindrical surface of the base through a keyway, used as a bearing, between the base body and the inner hole of the rocker arm assembly. The rocker arm assembly rotates on sliding bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com