A free piston buffer mechanism

A technology of buffer mechanism and piston, applied in the field of buffer mechanism, can solve problems such as collision, and achieve the effect of improving safety, compact structure and stable buffer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

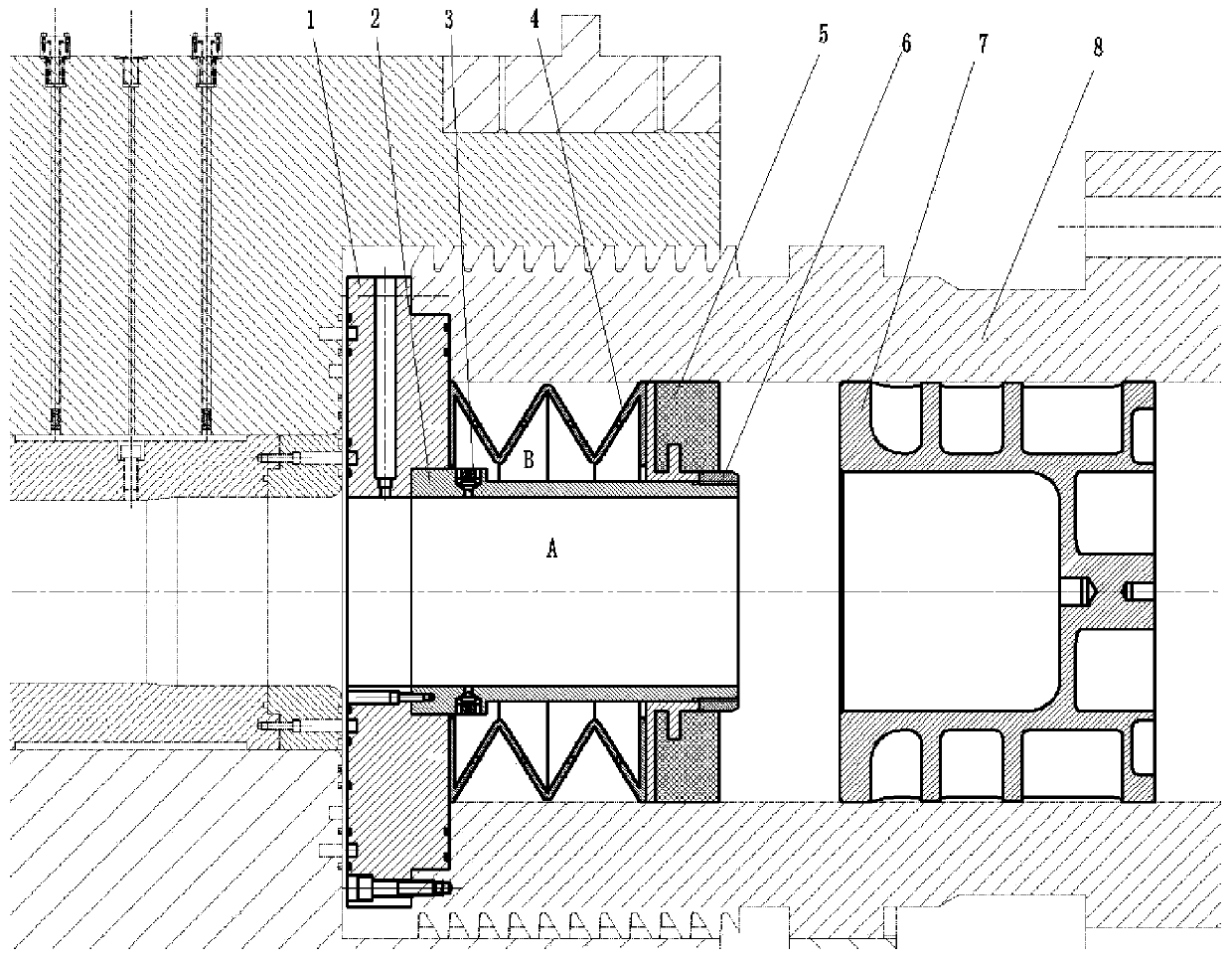

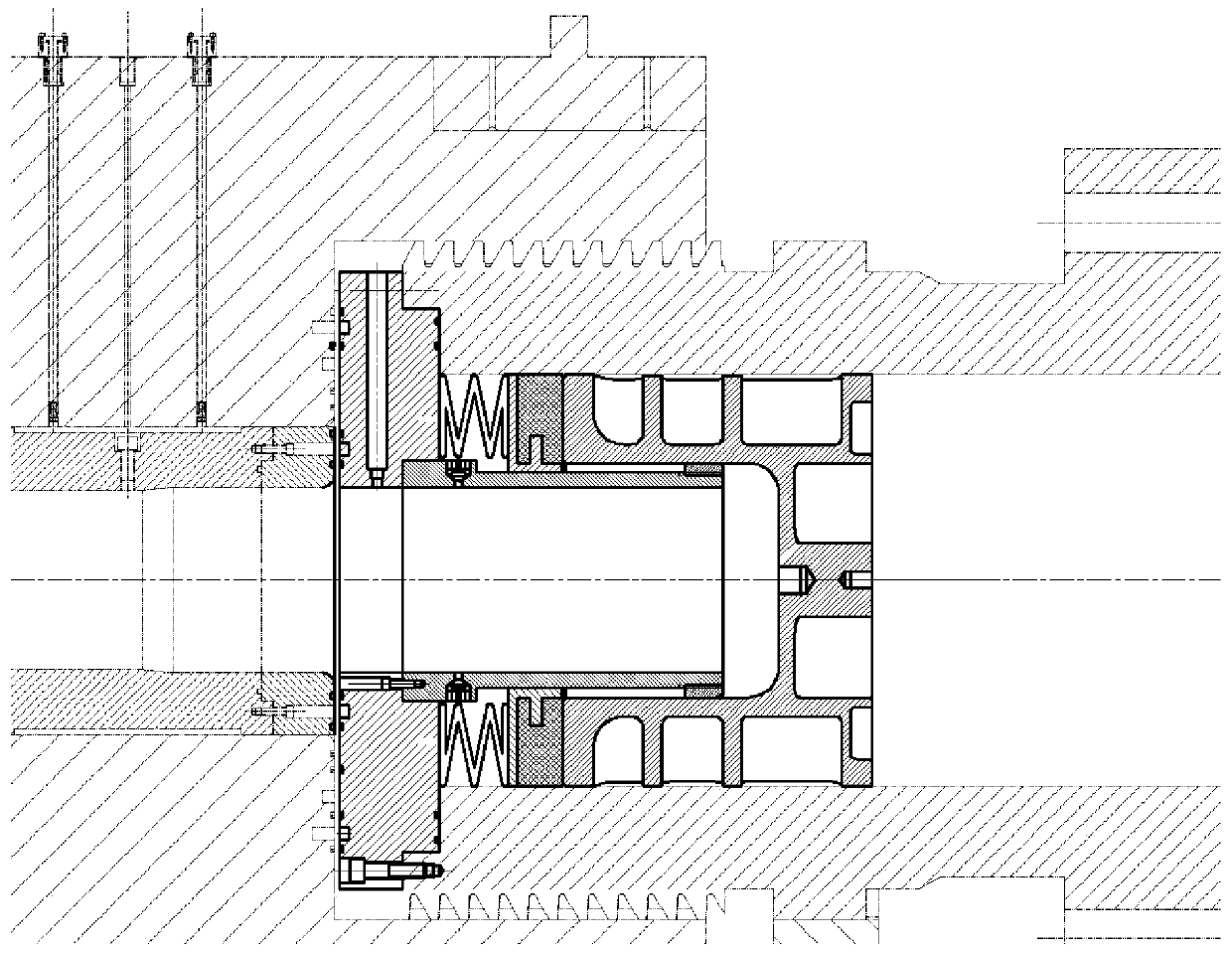

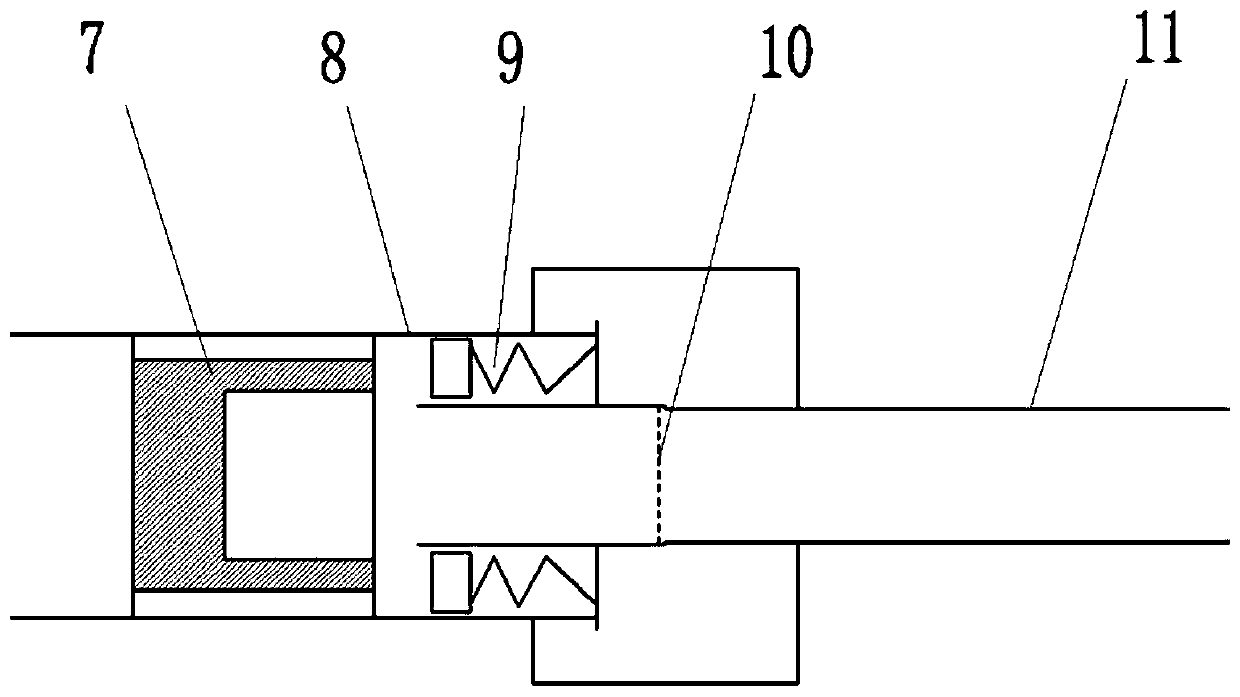

[0029] to combine image 3 , the wind tunnel body includes a compression tube 8 and a shock tube 11, and the diaphragm 10 is held between the compression tube 8 and the shock tube 11 by a clamping mechanism. The free piston 7 is set in the compression tube 8 and can move freely in the axial direction to the end of the compression tube 8. If there is still a high speed at the end of the compression tube 8, the free piston 7 will directly collide with the clamping mechanism of the diaphragm 10 , resulting in damage. Therefore, the present invention increases the free piston buffer mechanism 9, which is arranged at the tail section of the compression tube 8 and the front part of the diaphragm 10 clamping mechanism.

[0030] to combine figure 1 , the free piston buffer mechanism, which is suitable for buffering the impact of the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com