Steel structure virtual pre-assembly method

A pre-assembled, steel structure technology, used in image data processing, special data processing applications, instruments, etc., can solve the problems of uncontrollable position, failure to disclose high-precision assembly of two adjacent steel structure parts, and insufficient installation accuracy. To achieve the effect of shortening the construction period, simple method and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific drawings and examples, so as to facilitate a clear understanding of the present invention, but they do not limit the present invention.

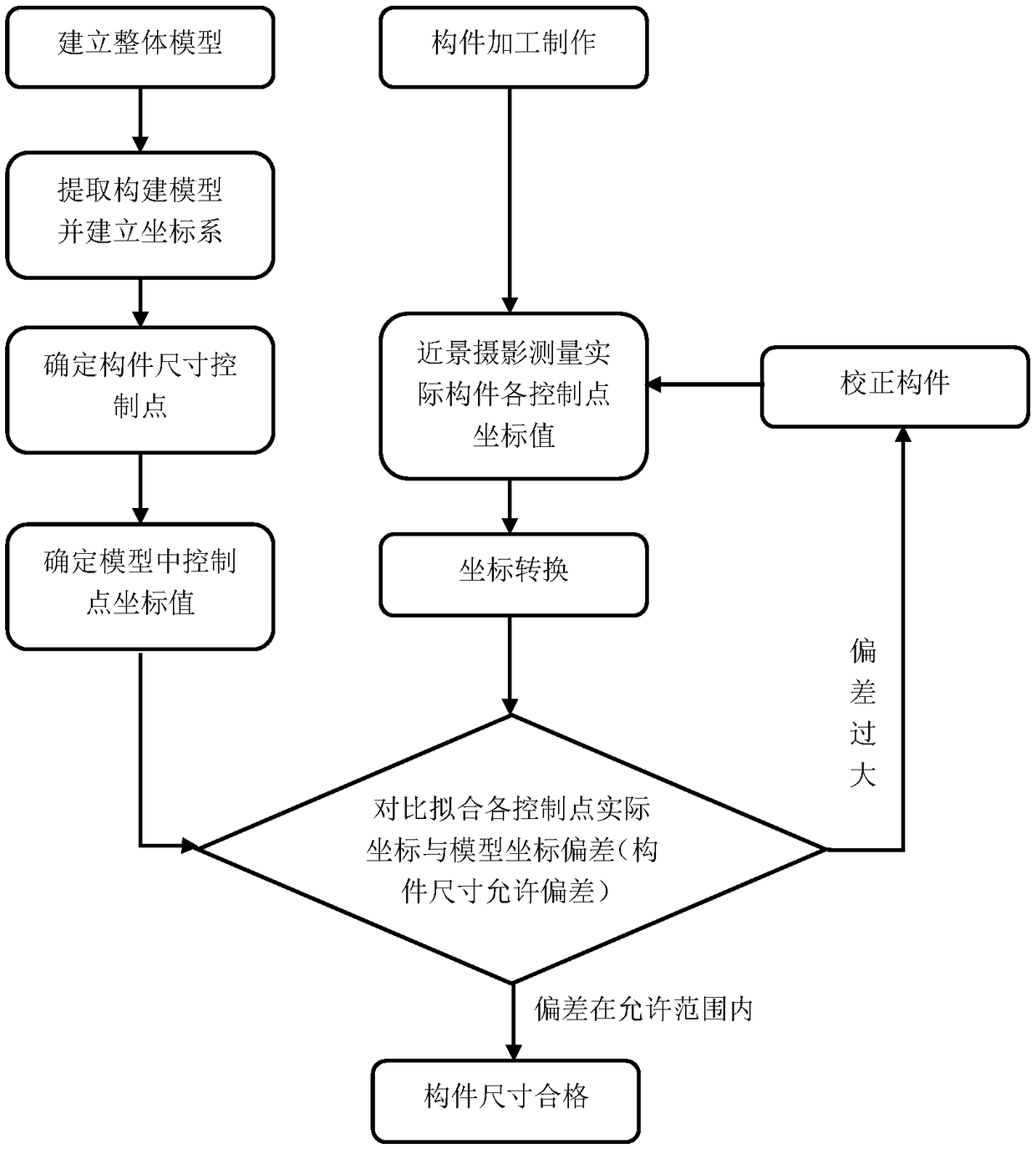

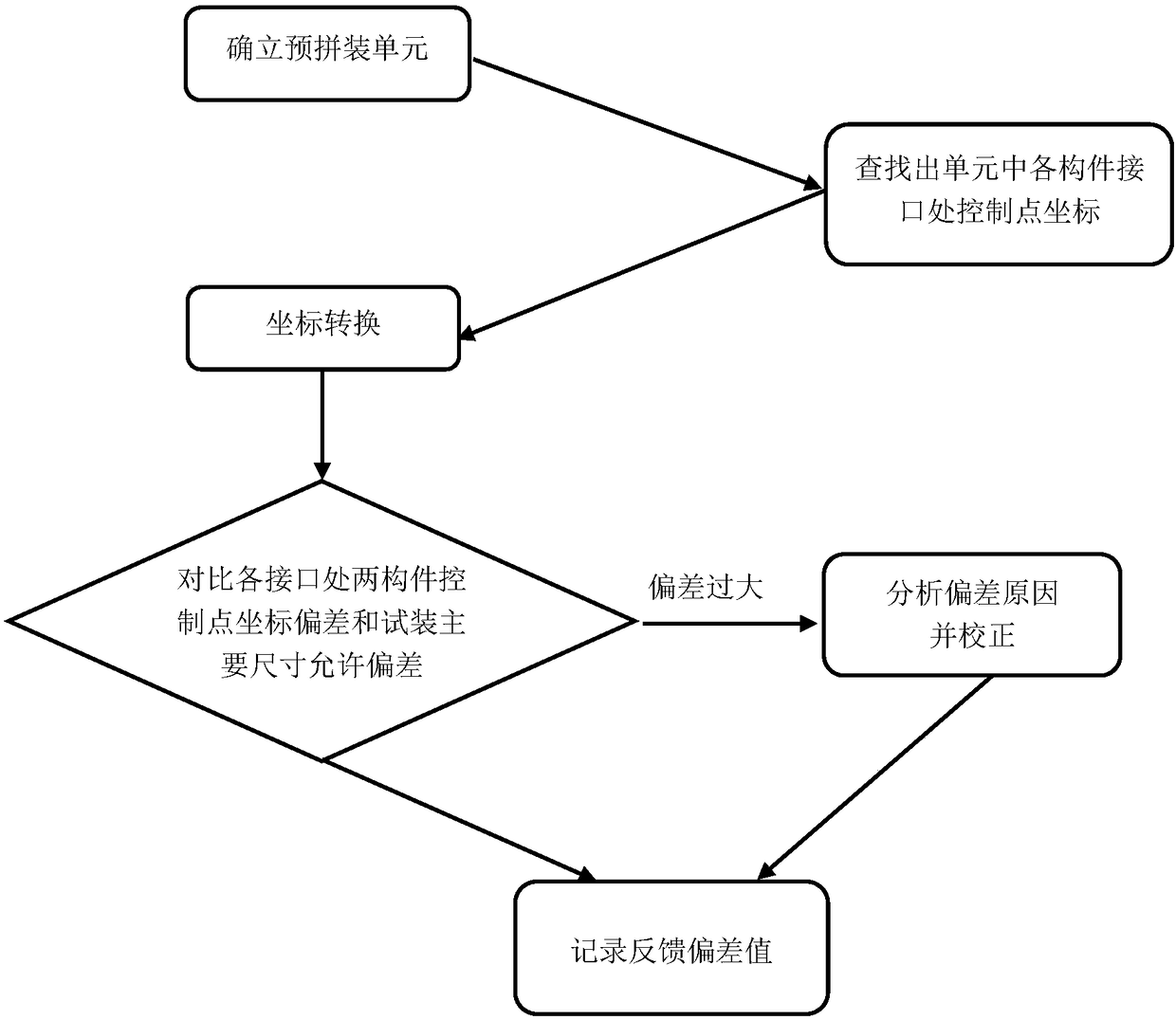

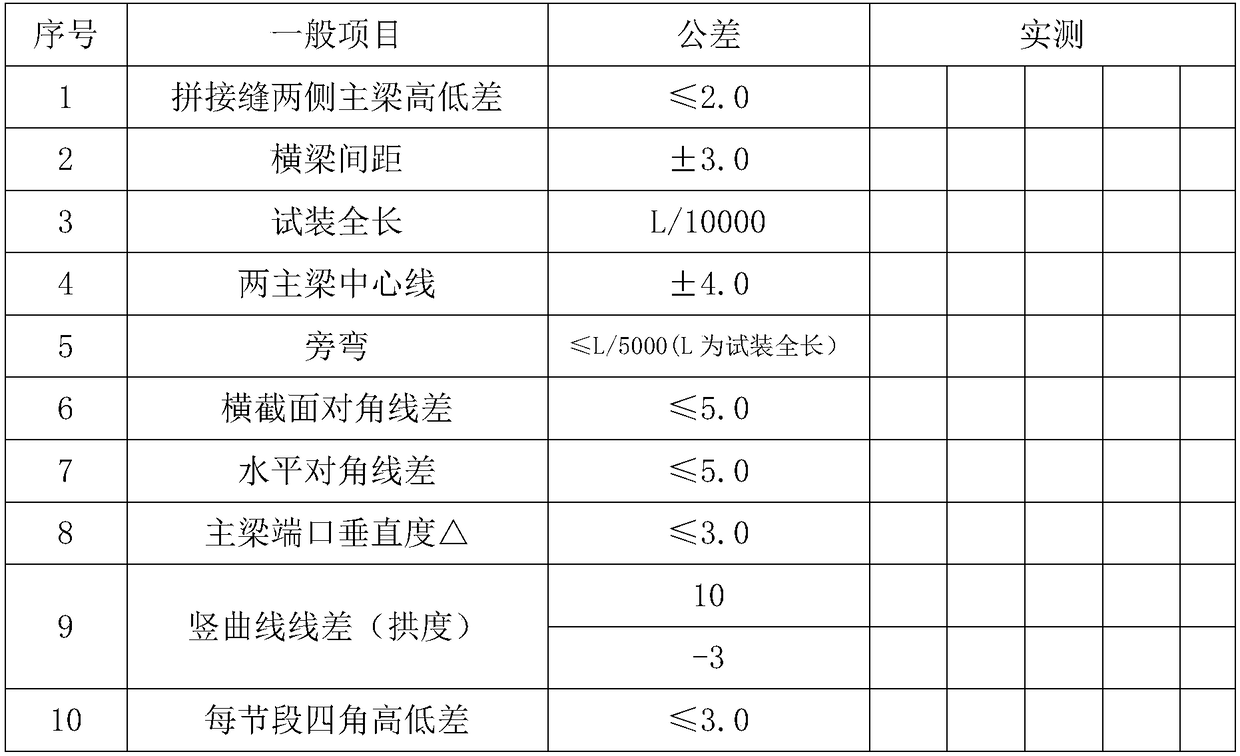

[0019] The purpose of the present invention is to provide a virtual pre-assembly technology for steel structures to address the above problems. The method specifically includes the following steps: (1) acquisition of measurement data of the structural member. (2) Acquisition of splice board design point data. (3) Assembly of structural parts. (4) Analysis of assembly accuracy. (5) Assembling a three-dimensional display.

[0020] Specifically, the step (1) is to select the structural member to be tested, number all the hole positions and feature points used for docking and detection, arrange photogrammetry tooling on the four corners of the docking hole group, and use digital The close-range photogrammetry system performs photogrammetry and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com