Evaluation method of plastic deformation performance of graded crushed stone based on pdi index

A graded crushed stone and plastic deformation technology, applied in data processing applications, instruments, calculations, etc., can solve the problem of single performance evaluation index of graded crushed stone, excessive plastic deformation of graded crushed stone base, objective and accurate deformation performance Evaluation and other issues, to achieve the effect of objective and reasonable plastic deformation performance, easy operation and clear concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] The optimized gradation of crushed stone aggregate gradation is shown in Table 1, and the results of vibration compaction test show that:

[0027] The optimum moisture content is 3.40%, and the maximum dry density is 2.47g / cm 3 .

[0028] Table 1 aggregate gradation

[0029] Sieve hole(mm) 31.5 19 9.5 4.75 2.36 0.6 0.075 Passing rate(%) 100 64 47 36 28 17.5 7.5

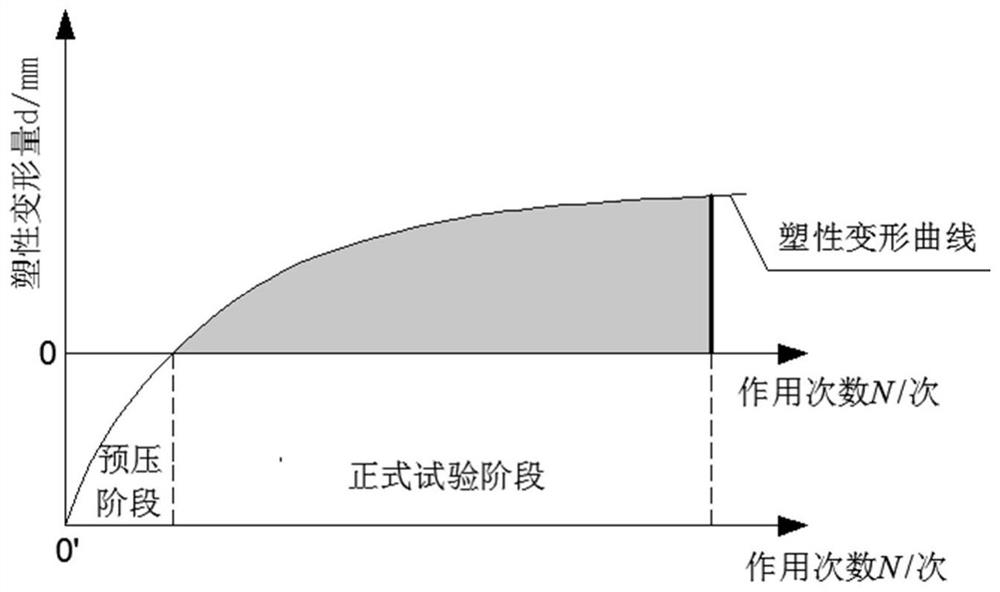

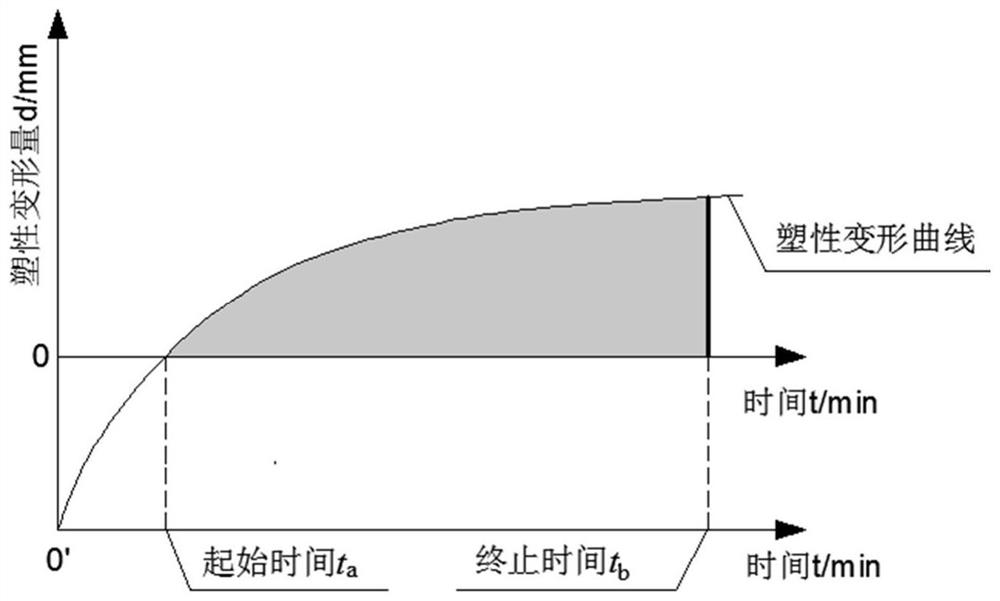

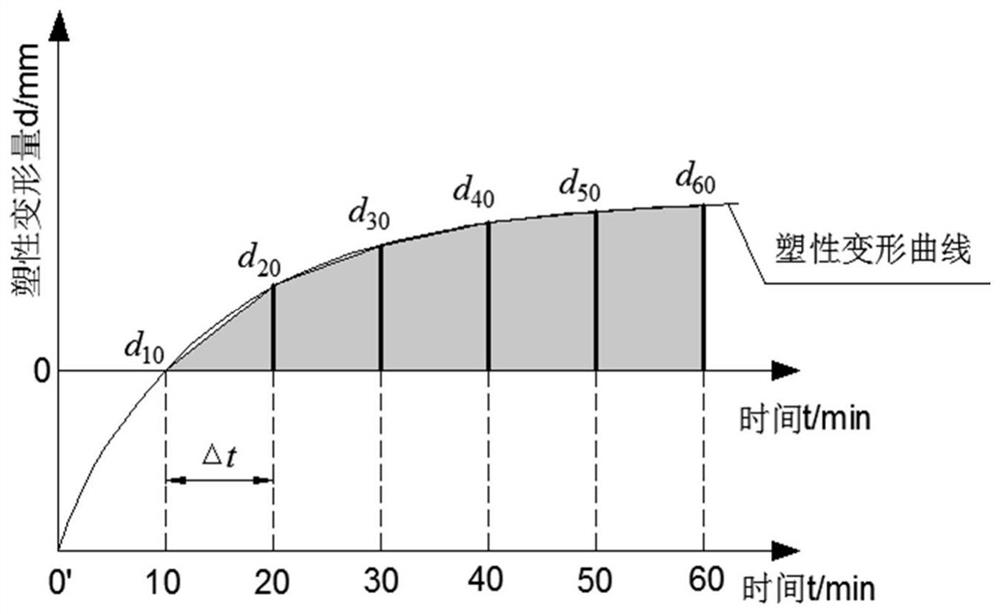

[0030] Plastic deformation tests were carried out on the graded crushed stone specimens in the optimal water content state and saturated state respectively.

[0031] Among them, the state of optimum moisture content means that after the specimen is formed (without demoulding), it is placed indoors for 4h to 5h, and then the plastic deformation test is carried out (at this time, the moisture content of the specimen is close to the optimum moisture content, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com