An intelligent device for filtering casting paint

A foundry coating and intelligent technology, which is applied in the fields of filtration and separation, casting molding equipment, fixed filter element filters, etc., can solve the problems such as the inability to meet efficient automatic production, the inability to realize intelligent filtration of coatings, and the easy sedimentation of foundry coatings. And the effect of small human influence factors, high labor intensity and high-quality filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

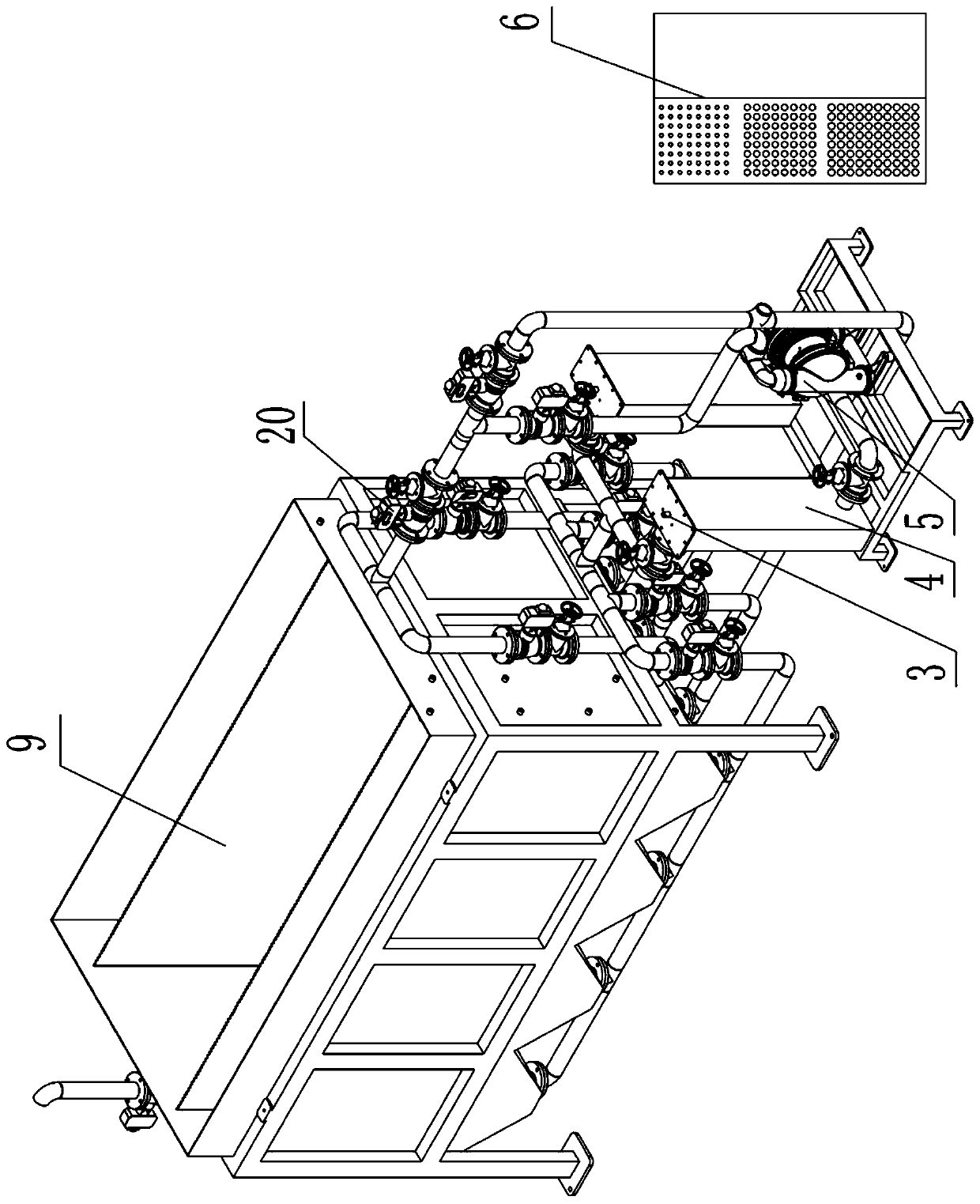

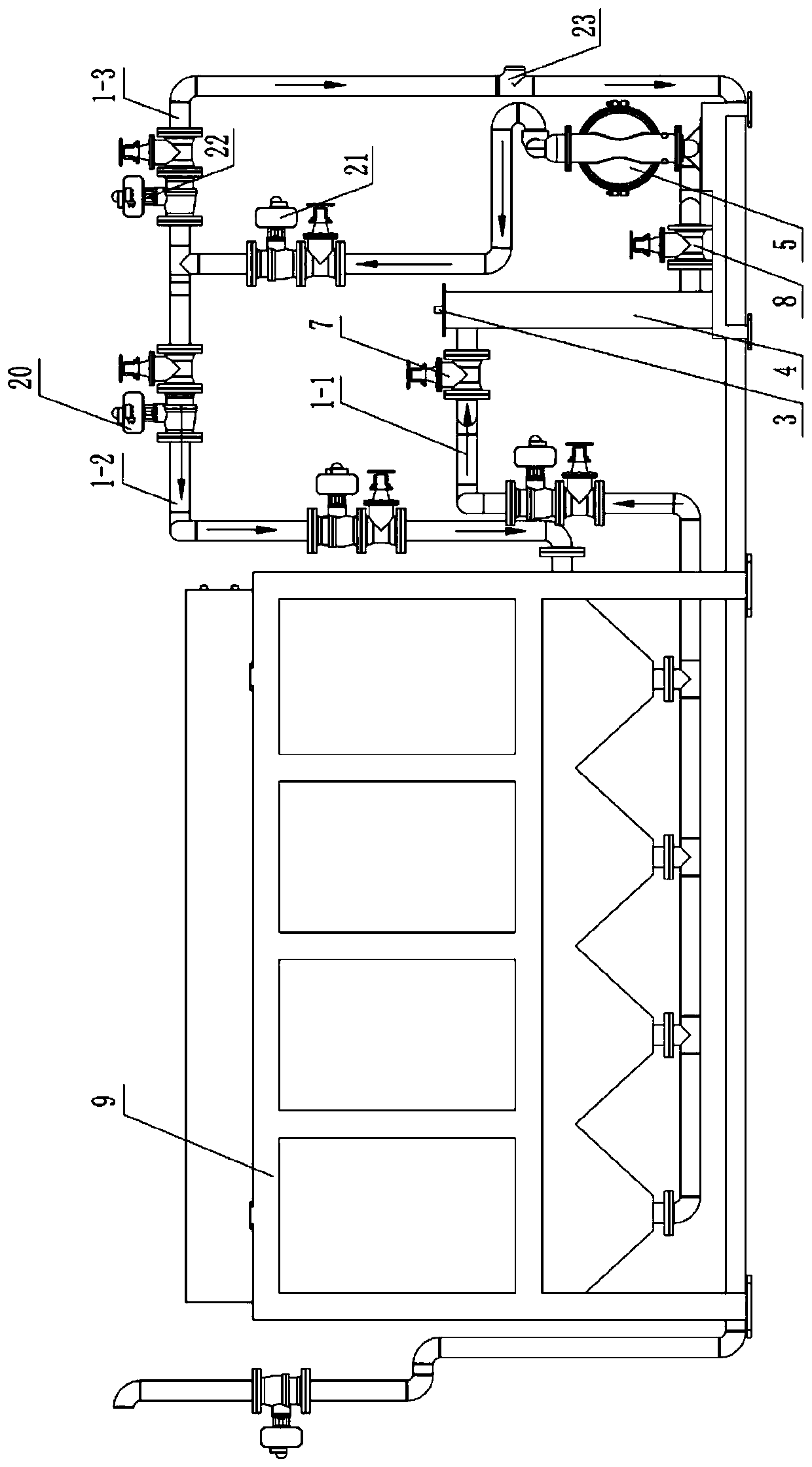

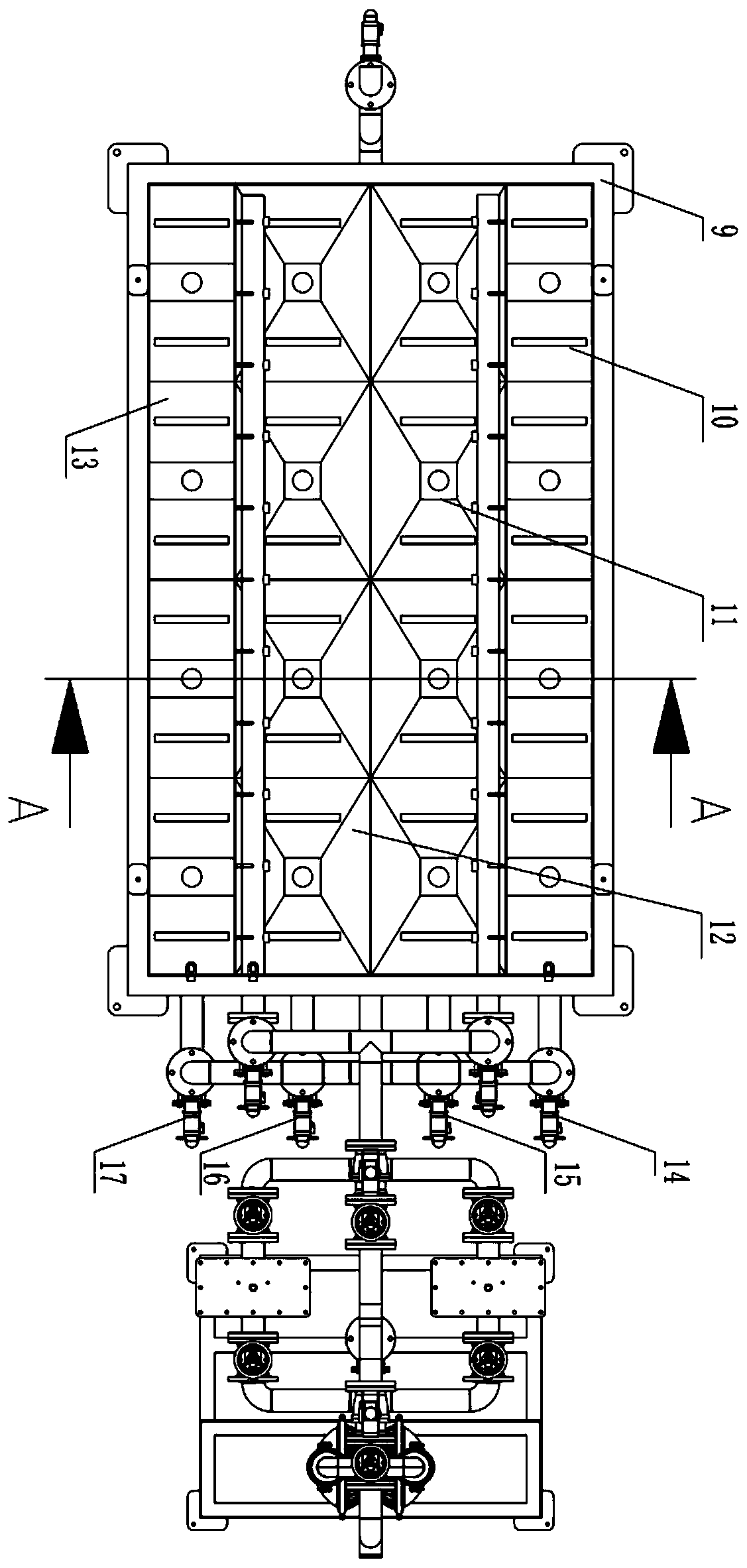

[0018] A device for intelligently filtering casting coatings, the structure comprising: a dipping pool 9 for applying coating to casting molds and sand cores, a backflow chamber 10, a dipping chamber 11, and a dipping chamber 11 sequentially connected to the bottom of the dipping pool 9. Coating 2 chamber 12, backflow 2 chamber 13, the return pipeline 1-1 respectively connected with backflow 1 chamber 10, dip coating 1 chamber 11, dip coating 2 chamber 12, and backflow 2 chamber 13 are all equipped with a return main valve, and The first main backflow valve 14, the second main backflow valve 15, the third main backflow valve 16, the fourth main backflow valve 17, and the first main backflow valve 14, the second main backflow valve 15, and the third main backflow valve 16 1. The filter chamber 4 communicated with the fourth backflow master valve 17 is used to filter the casting paint, the variable diameter inlet ball valve 7 arranged at the input end of the filter chamber body 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com