Nitriding Furnace Roof Material Distribution Method and Equipment for Lime Nitrogen Multifunctional Fertilizer Production

A multifunctional, nitriding furnace technology, applied in nitrogen fertilizers, calcareous fertilizers, inorganic fertilizers, etc., can solve the problems of easy softening and deformation of distributor chutes, easy bearing damage, high equipment maintenance costs, and reduce equipment maintenance and use. cost, achieve the effect of heat exchange and cooling, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

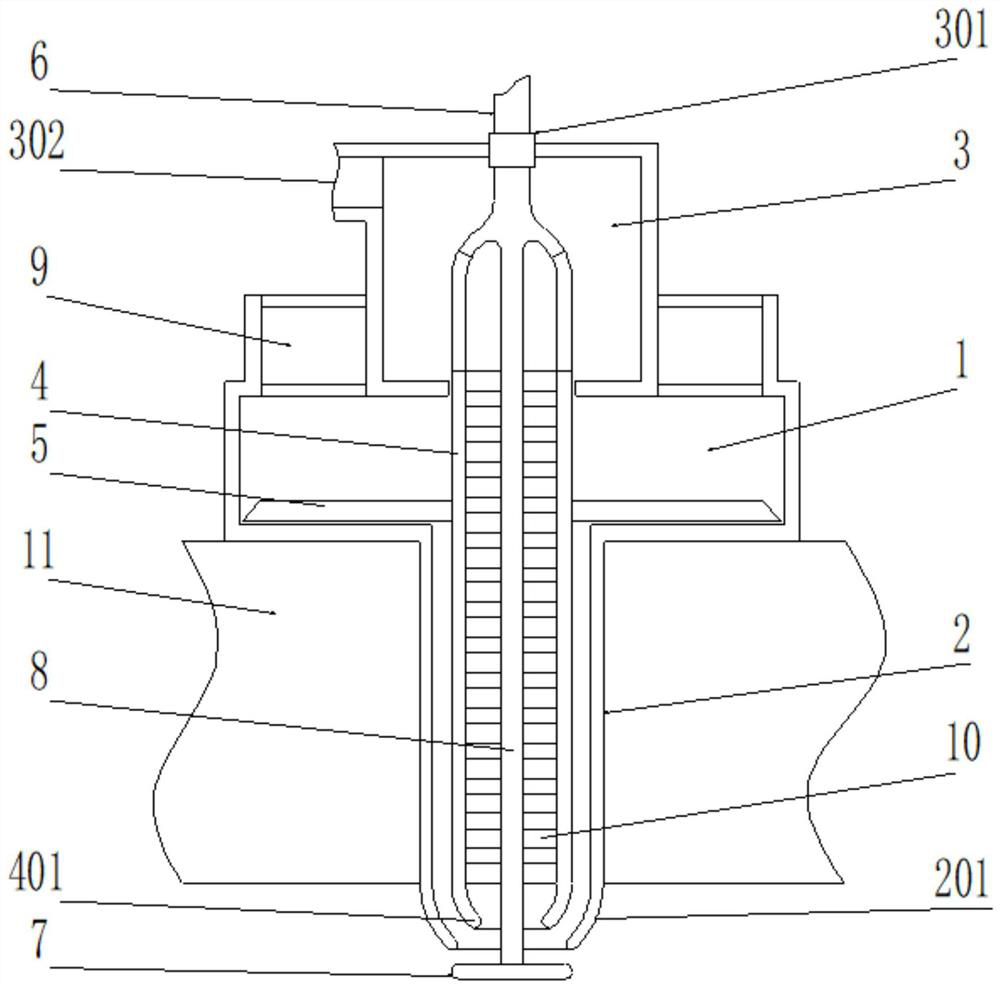

[0029] The method for distributing material on the roof of a nitriding furnace for the production of lime nitrogen multifunctional fertilizer comprises the following steps:

[0030] Step 1: Grind calcium carbide and other additives to below 60 mesh, said other additives include returned lime, nitrogen, etc., and mix them evenly;

[0031] Step 2: Stack the mixed material in the silo, push the material through the rake plate, so that the material is evenly dispersed in the silo;

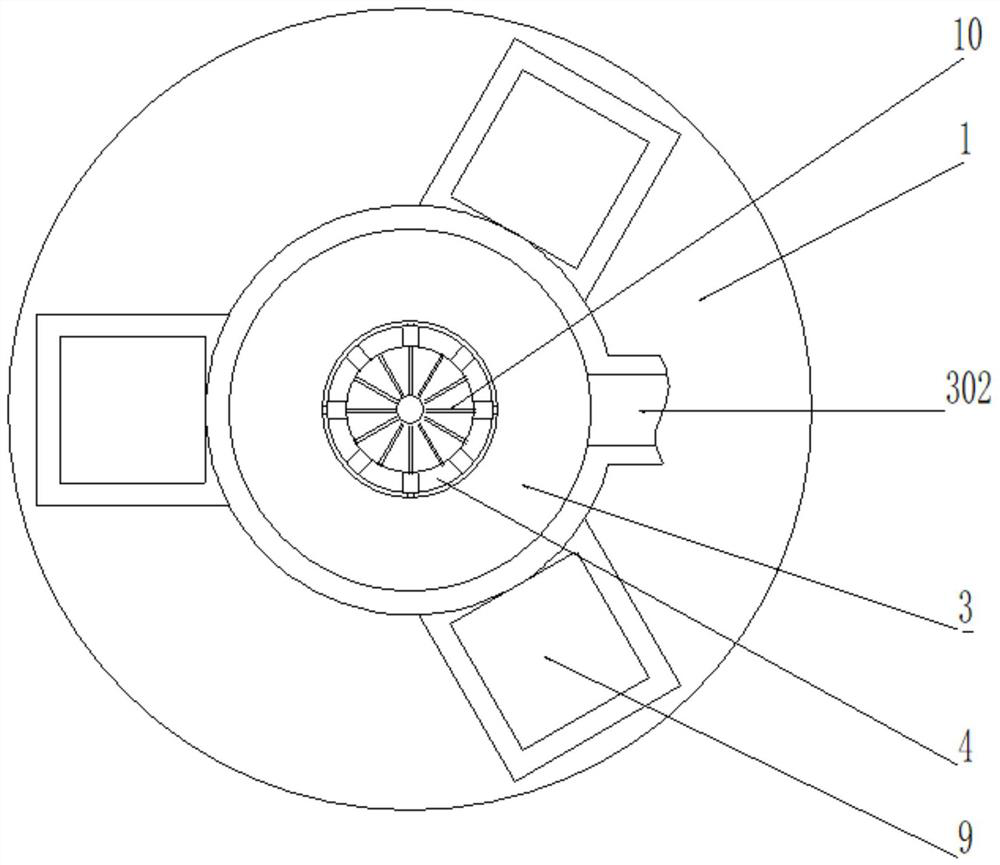

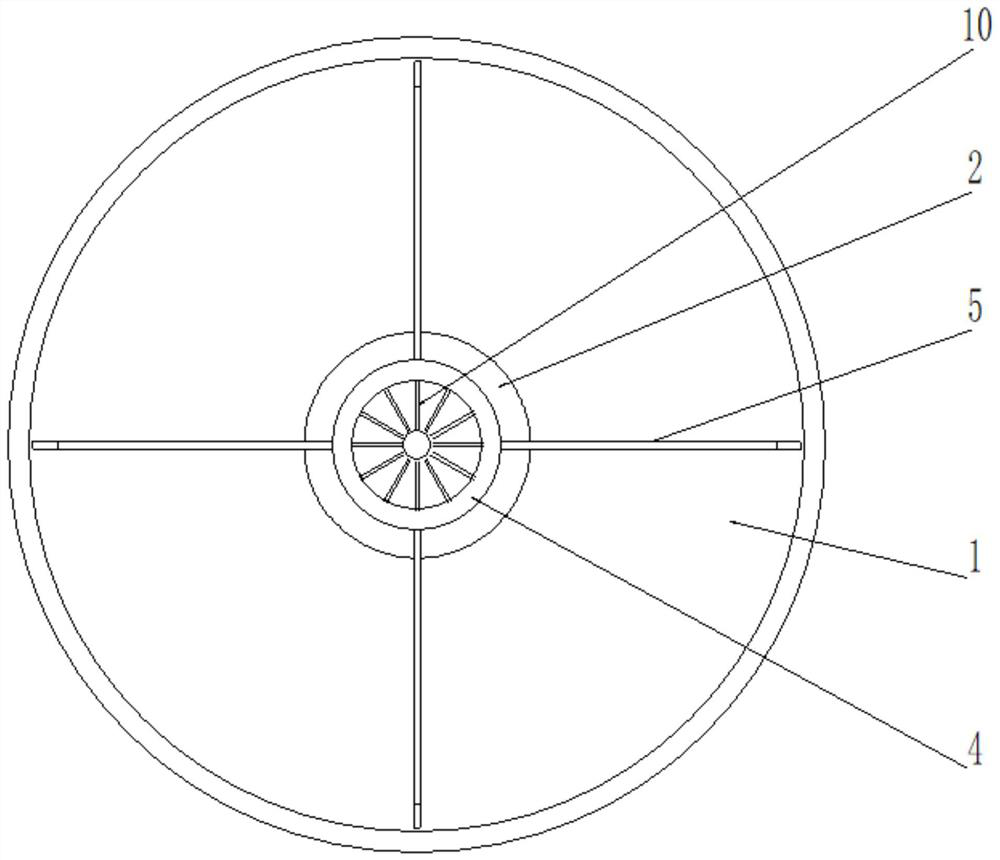

[0032] The above-mentioned silo is a circular silo, and the center of the bottom surface of the silo is provided with a drop hole, and the rake plate is a square plate, one side of which is close to the bottom surface of the silo, and the rake plate rotates around the drop hole to push the material;

[0033] Step 3: After the material rotates and disperses with the rake plate, it continues to be agitated by the rake plate, and falls from the drop hole when it moves to the center of the silo;

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com