Reflecting heat-insulating coating and preparation method thereof

A technology of thermal insulation coating and coating, applied in the direction of reflective/signal coatings, coatings, etc., can solve the problems of reduced mechanical properties of coatings, difficulty in achieving thermal insulation effect and balance of mechanical properties, poor thermal insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

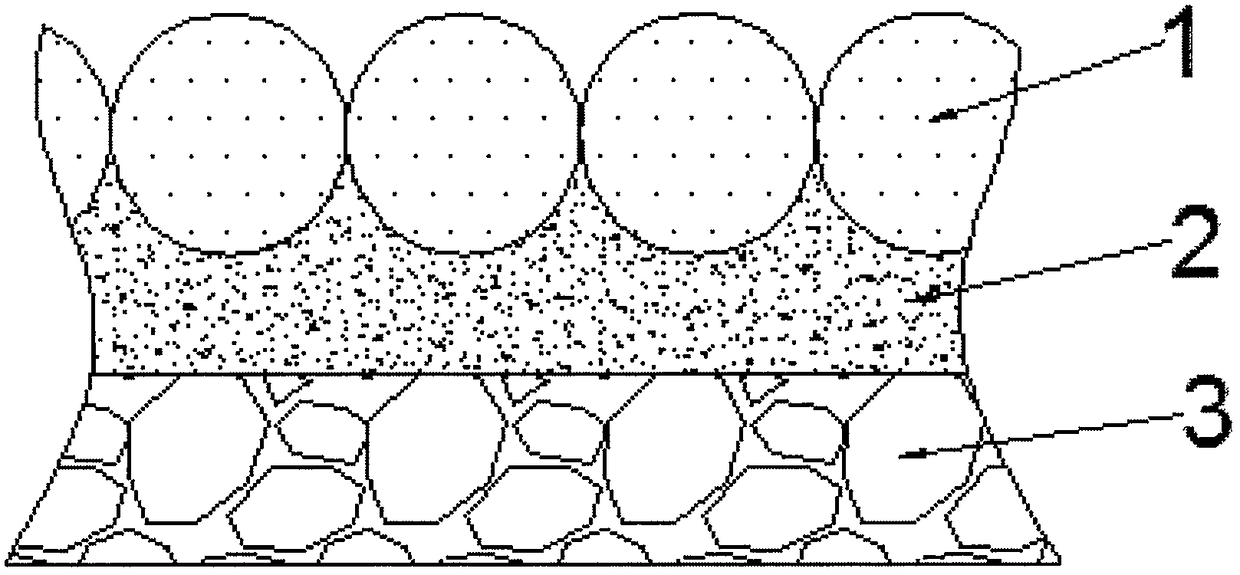

Image

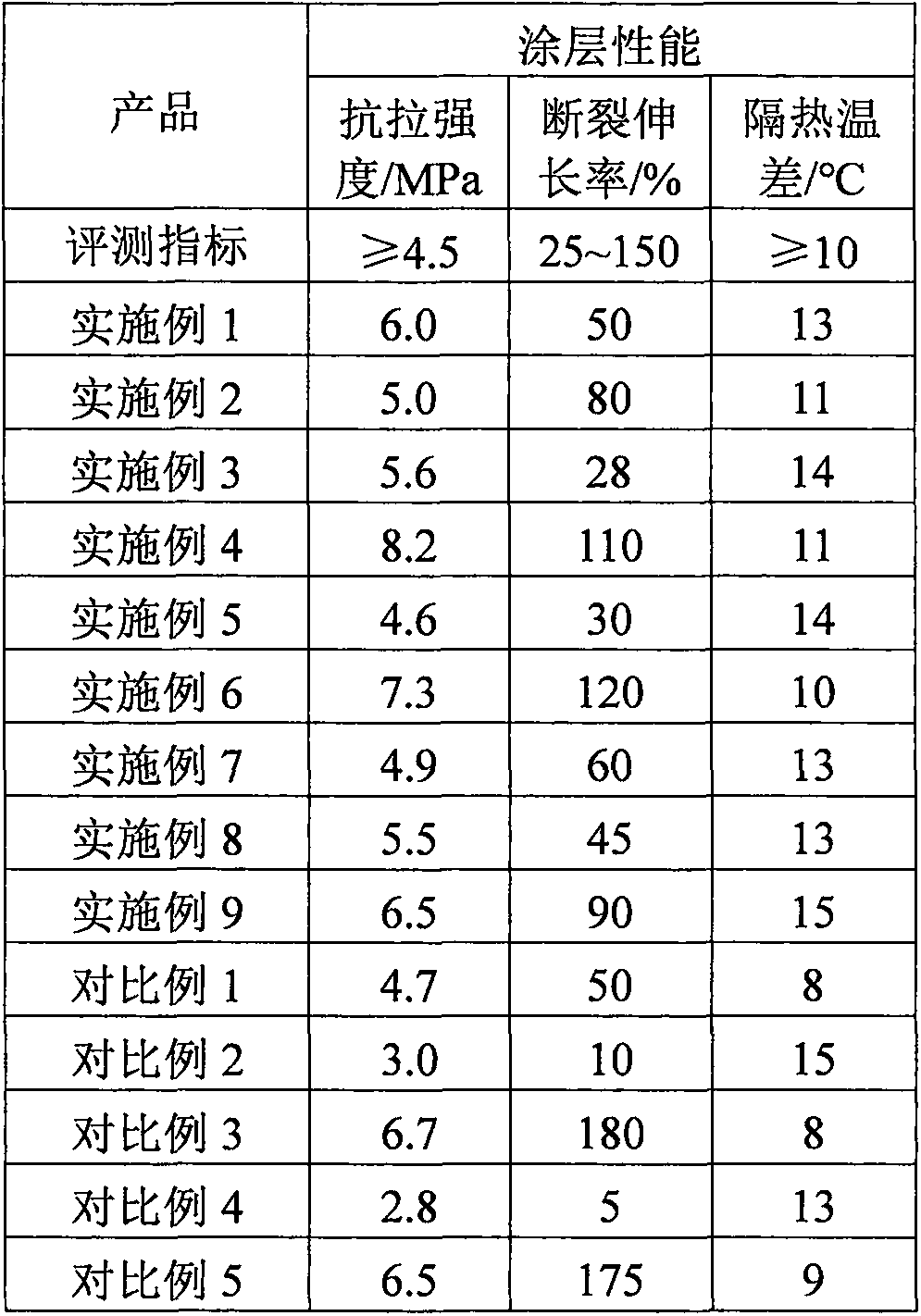

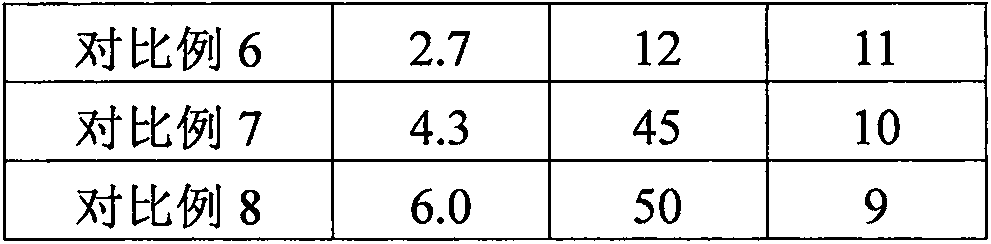

Examples

Embodiment 1

[0026] (1) The parts by weight of some raw materials in the basic coating are:

[0027] Titanium dioxide filler, 25 parts

[0028] Hollow glass microspheres, 8 servings

[0029] Hollow polymer microspheres, 10 parts

[0030] Film-forming resin emulsion, 60 parts

[0031] Various additives, 5 parts

[0032] (2) The preparation steps include:

[0033] a. Disperse a certain amount of surface-modified hollow glass microspheres in a solvent to obtain dispersion A;

[0034] b. Spray a certain amount of dispersion liquid A evenly on the surface of a certain area of release paper to obtain glass microbead transfer paper;

[0035] c. Spray a 400μm first base coat paint on the surface of the substrate;

[0036] d. After the first base coat is dry, spray a second base coat of 80 μm on the surface;

[0037] e. Before the surface of the second base coating is dry, paste the side of the glass microbead transfer paper containing glass microbeads on the surface of the reflective coat...

Embodiment 2

[0040] (1) The parts by weight of each raw material in the basis are:

[0041] Titanium dioxide filler, 20 parts

[0042] Hollow glass microspheres, 8 servings

[0043] Hollow polymer microspheres, 10 parts

[0044] Film-forming resin emulsion, 60 parts

[0045] Various additives, 5 parts

[0046] (2) The preparation steps include:

[0047] a. Disperse a certain amount of surface-modified hollow glass microspheres in a solvent to obtain dispersion A;

[0048] b. Spray a certain amount of dispersion liquid A evenly on the surface of a certain area of release paper to obtain glass microbead transfer paper;

[0049] c. Spray a 400μm first base coat paint on the surface of the substrate;

[0050] d. After the first base coat is dry, spray a second base coat of 80 μm on the surface;

[0051] e. Before the surface of the second base coating is dry, paste the side of the glass microbead transfer paper containing glass microbeads on the surface of the reflective coating, and ...

Embodiment 3

[0054] (1) The parts by weight of each raw material in the basis are:

[0055] Titanium dioxide filler, 30 parts

[0056] Hollow glass microspheres, 8 servings

[0057] Hollow polymer microspheres, 10 parts

[0058] Film-forming resin emulsion, 60 parts

[0059] Various additives, 5 parts

[0060] (2) The preparation steps include:

[0061] a. Disperse a certain amount of surface-modified hollow glass microspheres in a solvent to obtain dispersion A;

[0062] b. Spray a certain amount of dispersion liquid A evenly on the surface of a certain area of release paper to obtain glass microbead transfer paper;

[0063] c. Spray a 400μm first base coat paint on the surface of the substrate;

[0064] d. After the first base coat is dry, spray a second base coat of 80 μm on the surface;

[0065] e. Before the surface of the second base coating is dry, paste the side of the glass microbead transfer paper containing glass microbeads on the surface of the reflective coating, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com