Low-temperature grain-storing integrative method

A comprehensive method and low-temperature technology, applied in the field of grain temperature control in grain storage, can solve the problems of high compressive strength, poor economy, inability or limited use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

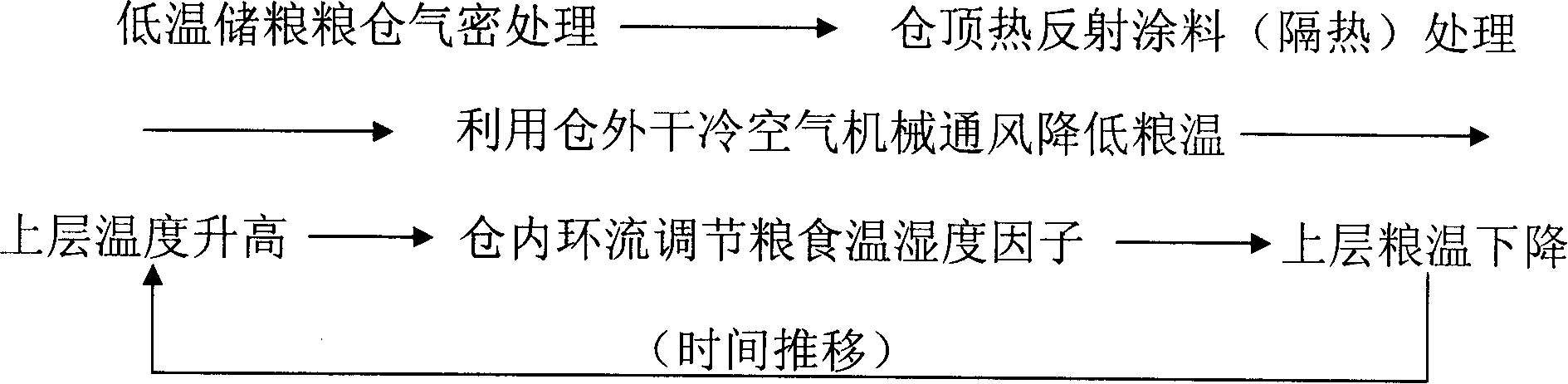

Method used

Image

Examples

Embodiment

[0021] Tall one-story warehouse or shallow round warehouse, the length of the warehouse is 42 meters, the width is 36 meters, the height of the eaves is 9.8 meters, the height of the ridge is 12 meters, and the height of the grain is 7.5 meters. Screws are forbidden, and its projected area is 1512m 2 , the expanded area is 1880m 2 .

[0022] 1. Carry out airtight treatment: that is, use sealant on the joints of the ridge opening (roof panel), cornice, roof panel joints, wall doors, gates, windows, fan outlets, cable outlets, wall cracks, etc. Sealing treatment, and add a sealing surface with foam plastic board or other materials in the relevant parts.

[0023] 2. The roof of the warehouse is painted with heat-reflective paint. The main chemical components of heat-reflective paint are acrylic resin and titanium dioxide, and the reflectivity is 0.91. Before painting, wipe off the dust on the surface, remove the rust on the rusty place first, and then apply the heat-reflective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com