Roof anti-skid heat-insulation waterproof coating and preparation method thereof

A waterproof coating, anti-skid technology, applied in the direction of reflection/signal coating, coating, climate change adaptation, etc., can solve the problems of the anti-skid performance not being paid attention to, increasing the construction cost and construction difficulty, poor waterproof performance, etc., to achieve excellent isolation. Heat reflective performance and anti-skid performance, reduced energy consumption, excellent performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

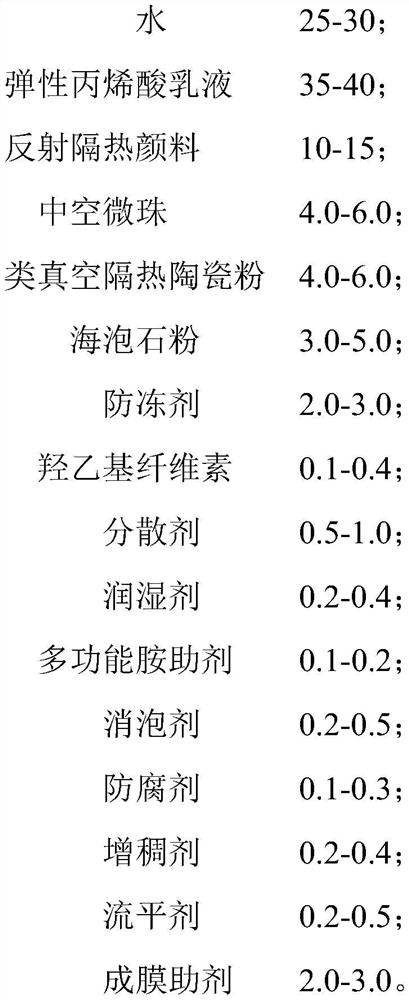

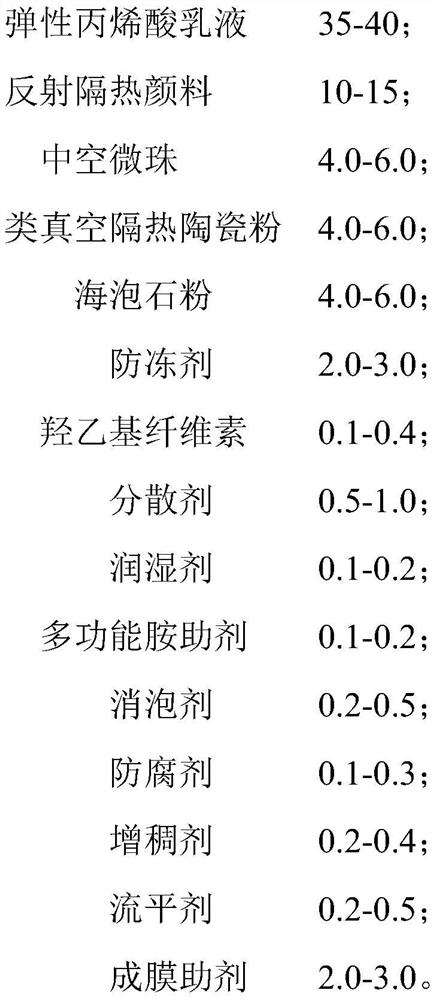

Method used

Image

Examples

Embodiment 1

[0033]A roof anti-slip, heat-insulating and waterproof elastic coating is composed of the following raw materials in the following parts by weight: water 29, elastic acrylic emulsion 35, titanium dioxide 15, hollow microspheres 5.0, vacuum-like heat-insulating ceramic powder 5.0, sepiolite powder 4.0, Antifreeze 2.0, hydroxyethyl cellulose 0.4, dispersant 0.8, wetting agent 0.3, multifunctional amine additive 0.1, defoamer 0.3, preservative 0.1, thickener 0.2, leveling agent 0.3, film-forming aid 2.5.

[0034] The product is obtained by the following preparation process:

[0035] Add 29kg of water into the dispersion tank, add 0.4kg of hydroxyethyl cellulose, and continue to disperse for 10-15min at a rotating speed of 800-1200r / min; then add 0.1kg of AMP-95 multifunctional amine additive during stirring, at this time The hydroxyethyl cellulose solution will thicken rapidly, keep the rotation speed at 800-1200r / min to disperse for 1-2min; then add 0.3kg defoamer, 0.1kg preser...

Embodiment 2

[0037] A roof anti-slip, heat-insulating and waterproof elastic coating is composed of the following raw materials in the following parts by weight: 30 parts of water, 35 parts of elastic acrylic emulsion, 15 parts of titanium dioxide, 4.0 of hollow microspheres, 5.0 of vacuum-like heat-insulating ceramic powder, 4.0 of sepiolite powder, Antifreeze 2.0, hydroxyethyl cellulose 0.4, dispersant 0.8, wetting agent 0.3, multifunctional amine additive 0.1, defoamer 0.3, preservative 0.1, thickener 0.2, leveling agent 0.3, film-forming aid 2.5.

[0038] Obtained by the following preparation process:

[0039] Add 30kg of water into the dispersion tank, add 0.4kg of hydroxyethyl cellulose, and continue to disperse at a speed of 800-1200r / min for 10-15min; then add 0.1kg of AMP-95 multifunctional amine auxiliary agent while stirring, this The hydroxyethyl cellulose solution will thicken rapidly, keep the rotation speed at 800-1200r / min to disperse for 3-5min; then add 0.3kg defoamer, 0...

Embodiment 3

[0041] A roof anti-slip heat-insulating and waterproof elastic coating, which is composed of the following raw materials in the following parts by weight: 30% water, 35% elastic acrylic emulsion, 15% titanium dioxide, 5.0% hollow microspheres, 4.0% vacuum-like heat-insulating ceramic powder, 4.0% sepiolite powder, Antifreeze 2.0, hydroxyethyl cellulose 0.4, dispersant 0.8, wetting agent 0.3, multifunctional amine additive 0.1, defoamer 0.3, preservative 0.1, thickener 0.2, leveling agent 0.3, film-forming aid 2.5.

[0042] Obtained by the following preparation process:

[0043] Add 30kg of water into the dispersion tank, add 0.4kg of hydroxyethyl cellulose, and continue to disperse at a speed of 800-1200r / min for 10-15min; then add 0.1kg of AMP-95 multifunctional amine auxiliary agent while stirring, this The hydroxyethyl cellulose solution will thicken rapidly, keep the rotation speed at 800-1200r / min to disperse for 3-5min; then add 0.3kg defoamer, 0.1kg preservative, 0.3kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com