Reflective and heat-insulating colored sand, preparation method and application

A technology of colored sand and bottom sand, which is applied in the field of architectural coatings, which can solve the problems of coating surface pollution and low reflection performance, and achieve the effects of excellent weather resistance, colorful colors, and excellent reflection and heat insulation durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

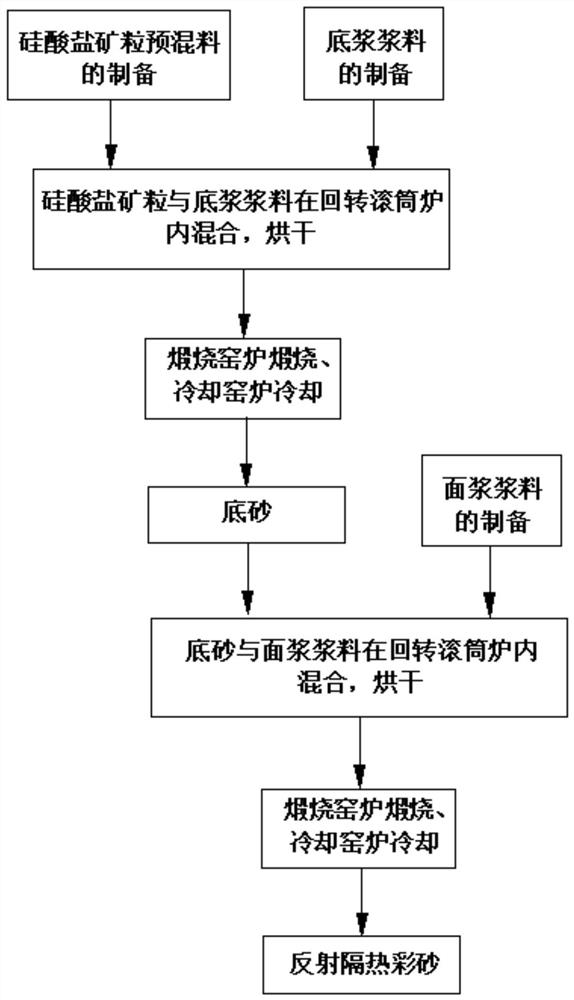

Method used

Image

Examples

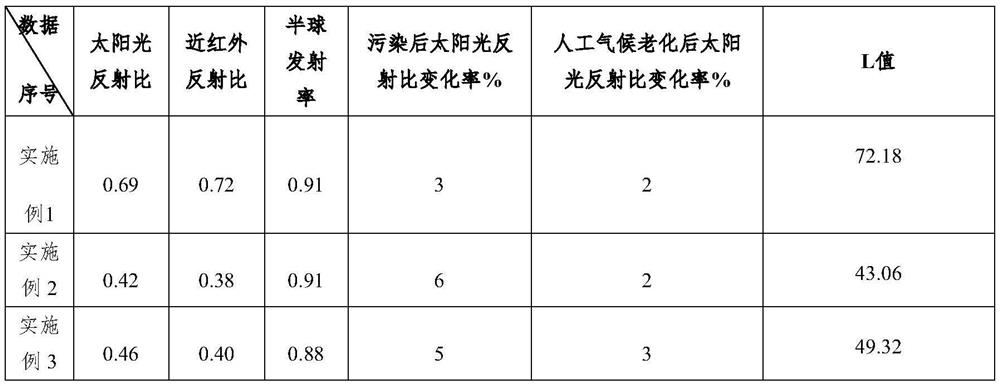

Embodiment 1

[0031] Preparation of yellow sand reflective insulation method of the present invention, comprising the steps of:

[0032] S1: Preparation of granulated silicate mineral premix: selected from silica sand # 6, # 7, # 8 sand, and gradation adjustment screen, and the granules according to the weight of silicate mineral different size ratio: 63% of 40-80 mesh, 80-120 mesh 20%, 17% mixed 120-200 mesh, silicate mineral particles to obtain a premix;

[0033] S2: the pulp slurry and the bottom surface of the pulp slurry was prepared:

[0034] Preparation of Substrate pulp slurry, the weight ratio of sodium silicate 38%, 22% kaolin, 8% industrial borax, 17% rutile titanium dioxide, nano zinc oxide 5% and 10% of water, was added dispersing machine sanding, grinding 1.2 h, undercoat pulp slurry;

[0035] Preparation of batter slurry, the sodium silicate 38%, 30% kaolin, titanium yellow as a yellow pigment cold 7%, and 5% rutile titanium dioxide was added 20% aqueous dispersion machine sandin...

Embodiment 2

[0039] The method of the present invention is prepared by the method of the present invention, including the following steps:

[0040] S1: Preparation of silicate mine premix: 6 #, 7 #, 8 # sand directly from quartz sand mine, and adjust the level with screens, and subtraction of different particle silts of silicate minerals according to weight Metals: 40-80 mesh 70%, 80-120 mesh 15%, 120-200 mesh 15% mixed uniform, silous silicate mine premix;

[0041] S2: Preparation of Squash Slurry and Slurry Slurry:

[0042] Preparation of the bottom slurry, 3% by weight of water glass, 27% kaolin, 1% industrial boar sand, 30% of golden-red stone powder, 10% nano-zinc oxide, 1% iron oxide (inorganic cold pig reinforcing agent) And the water is 1%, add a frosted dispersion, grind 1.5 h, and the bottom slurry is obtained;

[0043] Preparation of the slurry slurry, 30% of the water glass, 26% kaolin, 5% red cold pig powder, 10% of the golden-red stone powder, 29% in the water, 20%, grinding 1.5 ...

Embodiment 3

[0047] It is prepared by the method of the present invention to prepare a green reflective insulation, including the following steps:

[0048] S1: Preparation of silicate mine premix: 6 #, 7 #, 8 # sand directly from quartz sand mine, and adjust the level with screens, and subtraction of different particle silts of silicate minerals according to weight Metals: 40-80 mesh 80%, 80-120 mesh 10%, 120-200 mesh 10% mixed uniform, gadenilicate mine premix;

[0049] S2: Preparation of Squash Slurry and Slurry Slurry:

[0050] Preparation of the bottom slurry, the weight ratio is 48% of the water glass, 20% kaolin, 8% of the industrial bohaha, 10% of the golden-red stone powder, 8% nano-zinc oxide, 6%, add a frosted dispersion, grind 2h Get a bottoming slurry;

[0051] Preparation of the plasma slurry, 60% of the water glass, 20% kaolin, 10% of the green pigment toner, 6% of the golden-red, titanium white powder, and 4% water 4%, grinding 2 h, green plasma slurry;

[0052] S3: Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com