Graphene inorganic nano wall coating

An inorganic nanometer and graphene technology, applied in anti-corrosion coatings, reflective/signal coatings, coatings, etc., can solve problems such as poor adhesion, poor decoration, and large moisture absorption, and achieve low surface tension, difficult coating detachment, The effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

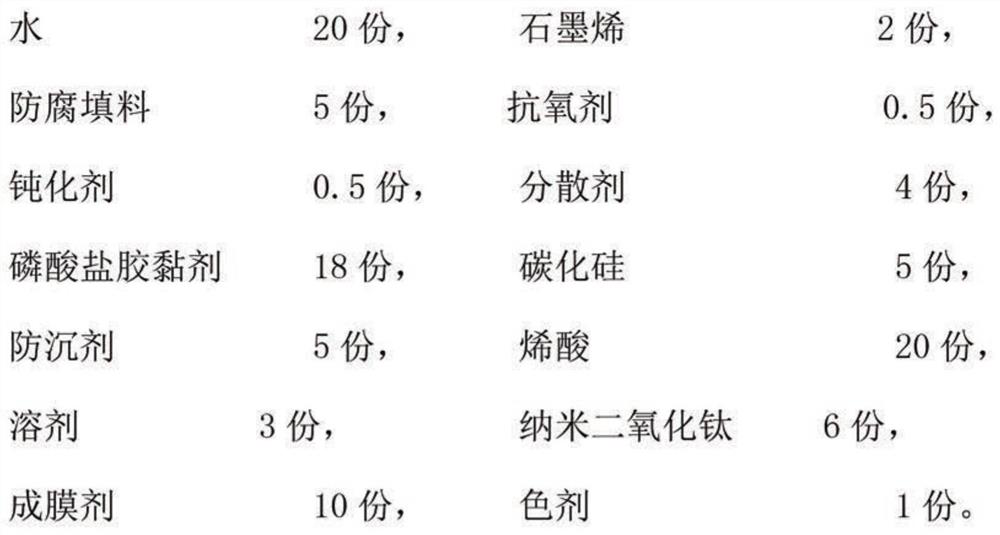

[0015] The present invention will be further described in detail below in conjunction with specific embodiments.

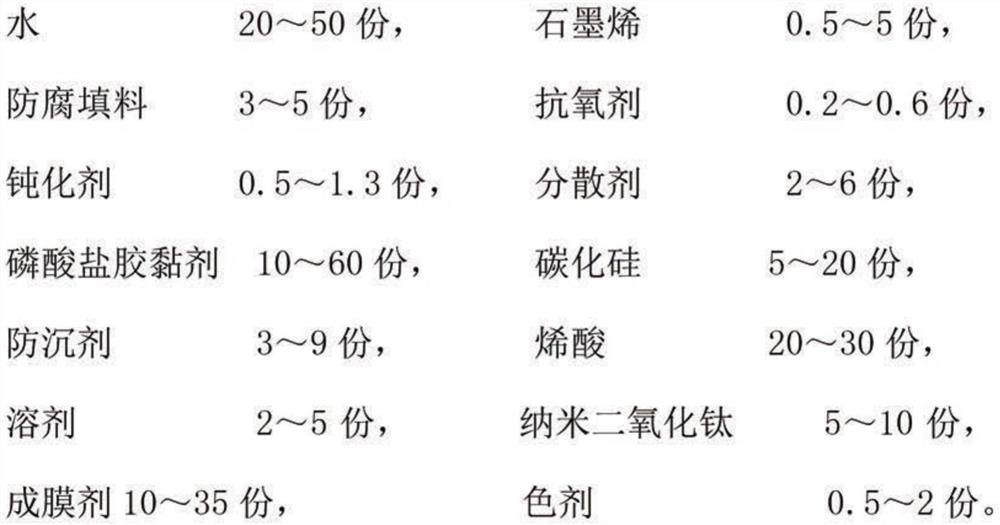

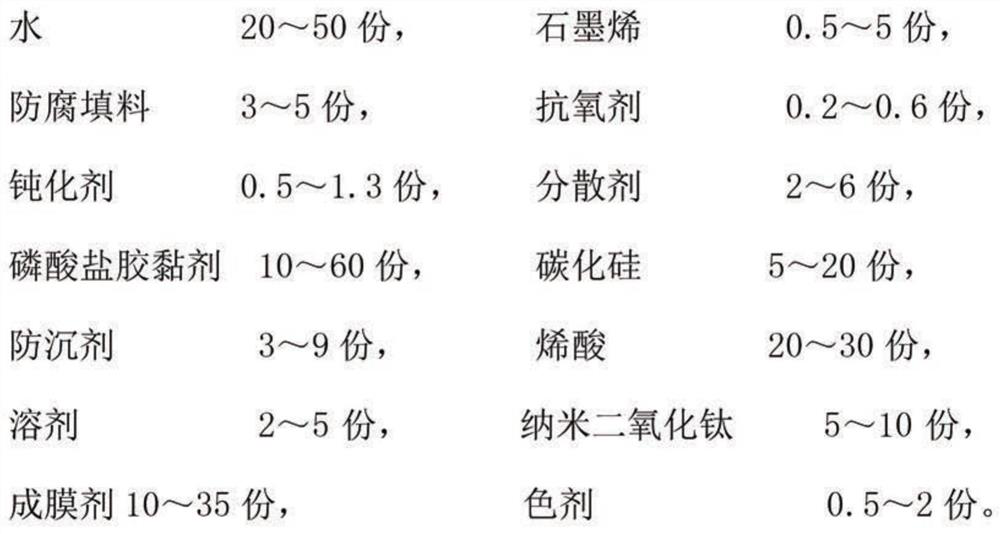

[0016] Present embodiment is used for graphene inorganic nanometer wall coating, and this formula comprises the material of following parts by weight:

[0017]

[0018] Graphene has a stable solvophilic group, which greatly improves the dispersion and stability of graphene in the dispersion medium, so that graphene can exist uniformly and stably in the coating for a long time. The two-dimensional lamellar structure of graphene is uniformly dispersed in the graphene-modified inorganic anti-corrosion coating, complements the anti-corrosion filler in the coating, or overlaps each other, or stacks each other, and fills in the inorganic skeleton constructed by the inorganic adhesive. Form a dense shielding layer to inhibit the entry of corrosive factors such as oxygen, chloride ions, and water molecules, so that the graphene-modified inorganic anti-corrosion coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com