Glass fiber reinforced plastic cooling tower with relatively high cooling effect

A cooling effect and FRP technology, applied in the field of cooling towers, can solve problems such as uneven water distribution, reduced cooling effect of cooling towers, poor ventilation, etc., and achieve the effects of improved cooling effect, reduced impeller diameter, and less fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

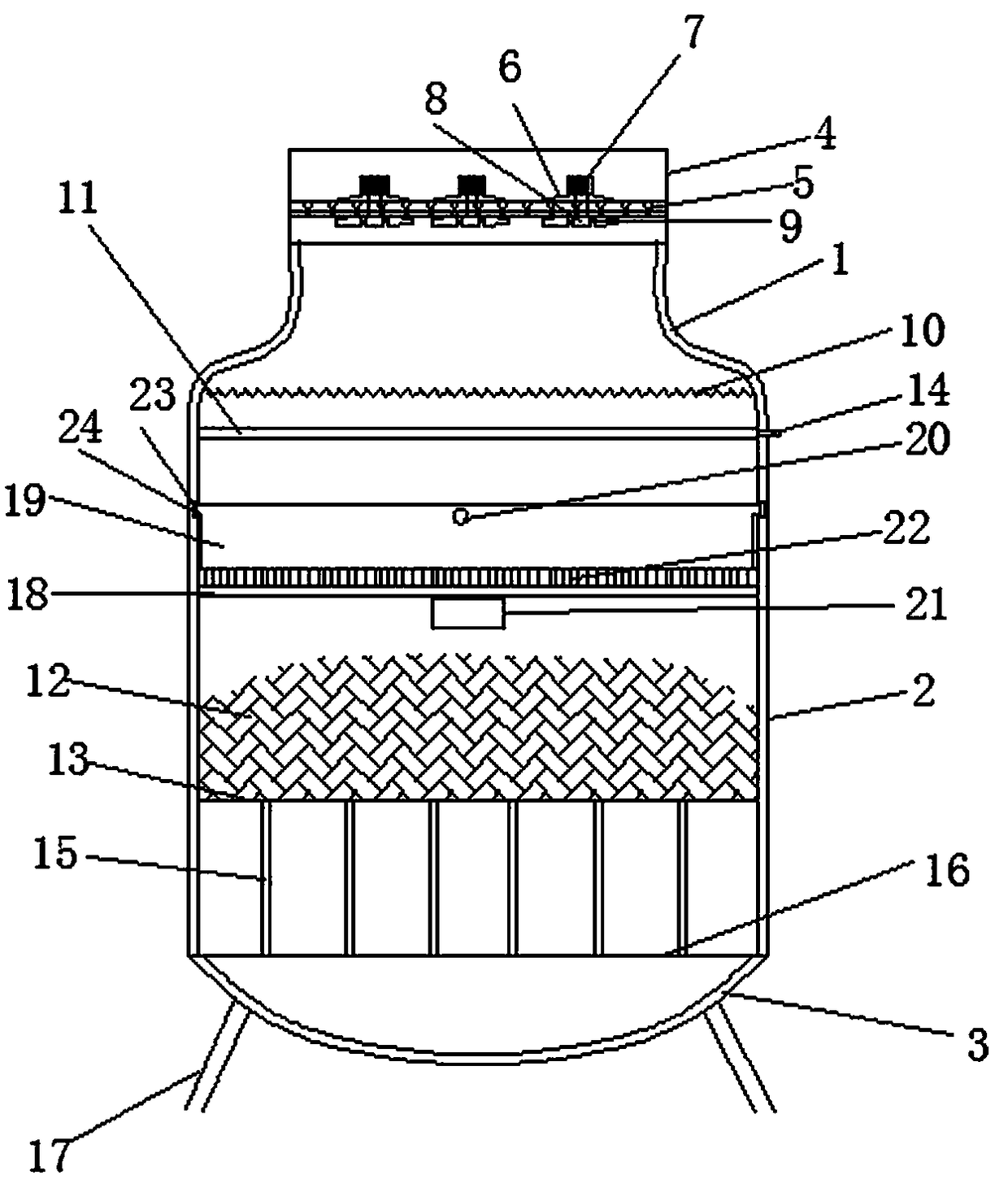

[0016] Embodiment 1: as figure 1 As shown, a FRP cooling tower with high cooling effect includes an upper shell 1, a middle shell 2, and a lower shell 3. The upper part of the upper shell 1 is connected with an air duct 4, and the air duct 4 is provided with a tuyere net inside. 5. There is a motor bracket 6 on the tuyere net 5, and three motors 7 are arranged on the motor bracket 6. The lower part of the motor 7 is connected to the reducer 8, and the lower part of the reducer 8 is connected to the fan 9; the upper shell 1 and the middle shell 2 are connected. ;The interior of the middle shell 2 is provided with a water eliminator 10, a water distribution pipe 11, a filler 12, and a filler bracket 13 in sequence from top to bottom; , the bamboo lattice filler has a longer service life and is not easy to silt and collapse. The wind mainly passes through the inside of the cooling tower, so the air volume in the middle is small. In order to improve the cooling effect in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com